Cross vertical SiO2 nanorod and preparation method thereof

A technology of nanorods and cross arrangement, which is applied in the field of crossed vertical SiO2 nanorods and its preparation, achieving the effects of high purity, low substrate requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Crossed perpendicular SiO2 according to the present invention 2 The preparation method of nanorod material, its step is as follows:

[0024] Step 1: pre-clean the substrate substrate, loaded quartz boat, and quartz tubes with openings at both ends;

[0025] The second step: put SiO powder as the reaction source into the quartz boat, and then cover the pretreated substrate with the bright side facing down on the reaction source in the quartz boat, but it cannot be in contact with the reaction source. Then put the quartz boat into the quartz tube with openings at both ends, and finally put the quartz tube reaction system into the tube furnace, and pass in the protective gas Ar;

[0026] Step 3: Raise the temperature of the furnace to make the source temperature in the furnace reach a suitable reaction temperature, and keep it warm for 3-4 hrs; after the reaction, lower the reaction temperature to room temperature and take out the quartz tube, and white flocs grow on the ...

Embodiment 1

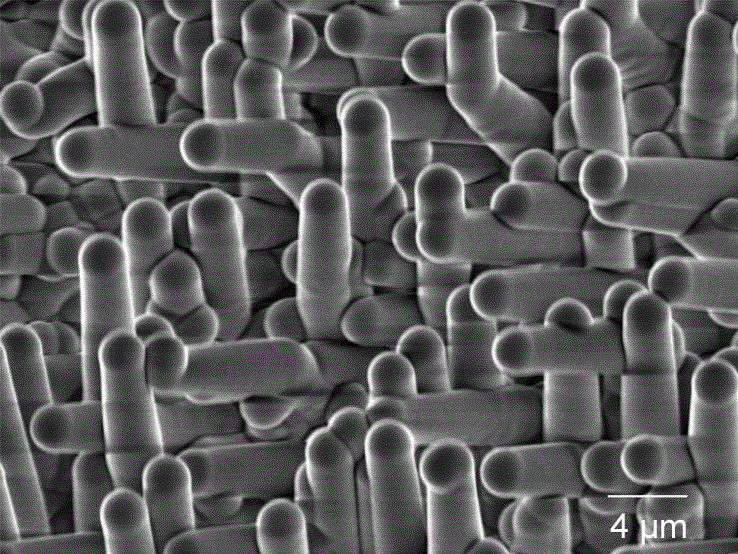

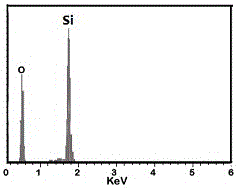

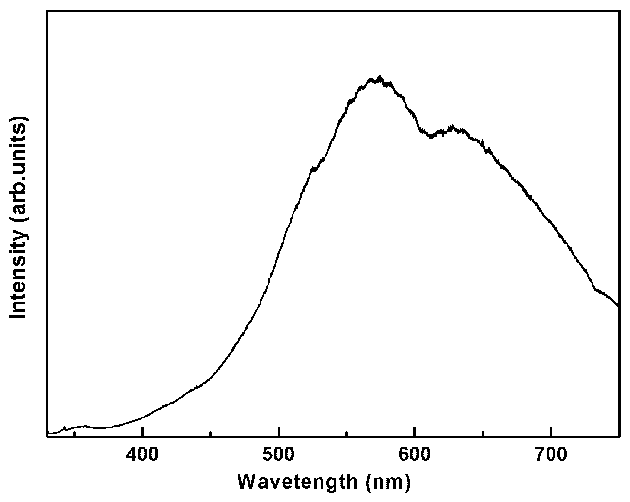

[0036] Put 0.4 g of SiO powder with a purity of 99.99% as a reaction source into a quartz boat, and then put the quartz boat into a quartz tube; use an n-type Si (111) piece as a substrate, clean it, and put it into a Place the substrate in the quartz boat at a distance of 0.7-3.7 cm from the furnace core, put the quartz boat equipped with the reaction source into the quartz tube, then put the quartz tube into the tube furnace, pass in the protective gas Ar, and control the flow at 80 sccm; turn on the heating component of the tube furnace, make the temperature of the reaction source in the furnace reach 1150 °C, the substrate temperature is about 1147-1150 °C, and keep the constant temperature for 3 hrs; cool down to room temperature and take out the quartz tube, that is, on the substrate Orderly growth of white flocculent vertically intersecting SiO 2 Nanorods, see figure 1 . figure 1 Medium SiO 2 The deposition temperature of the nanorods is about 1147 °C, and their diam...

Embodiment 2

[0038]Put 0.4 g of SiO powder with a purity of 99.99% as the reaction source into a quartz boat; use a quartz glass sheet as the substrate substrate, clean it, and place it along the quartz tube at a distance of 1.7-3.7 cm from the reaction source Substrate, put the quartz tube equipped with the reaction source and the substrate into the tube furnace, pass the protective gas Ar, and control the flow rate at 90 sccm; open the heating component of the tube furnace, so that the temperature of the reaction source in the furnace reaches 1050 ℃, the substrate temperature is 1040-1050 ℃, and kept at a constant temperature for 4 hrs; the quartz tube is taken out and lowered to room temperature, that is, white flocculent crossed vertical SiO is grown on the quartz substrate 2 Nano stave. The diameter of the grown nanorods is in the range of 100-800 nm, and the length is in the range of 0.5-4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com