Self-insulation high-strength environment-friendly concrete and preparation method thereof

An environmentally friendly concrete and high-strength technology, applied in the field of concrete, can solve the problems of poor compatibility between resin and concrete material interface, improper selection and treatment, and reduced concrete performance, so as to enhance strength performance, improve activation effect, increase strength and heat preservation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

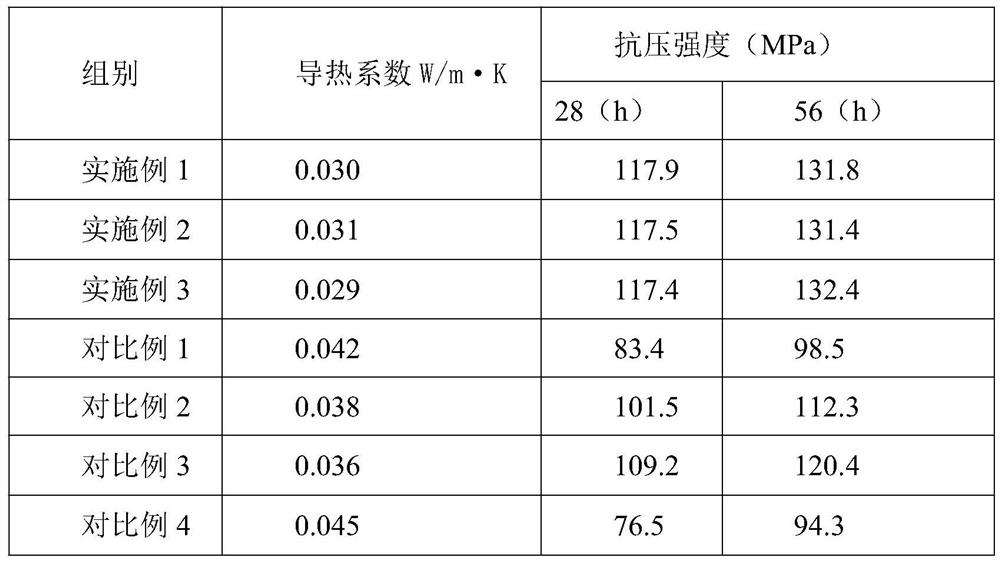

Examples

Embodiment 1

[0032] A kind of self-insulating high-strength environment-friendly concrete of the present embodiment comprises the following raw materials in parts by weight:

[0033] 200 parts of cement, 50 parts of mineral powder, 55 parts of fine sand, 30 parts of fly ash, 15 parts of modified styrene resin, 10 parts of activated bentonite, 5 parts of interface agent, 4 parts of water reducing agent and 180 parts of deionized water; The particle size of mineral powder is 100 mesh; the particle size of fine sand is 500 mesh; the particle size of fly ash is 50 mesh; the water reducer is sulfonated lignin water reducer;

[0034] The preparation method of described improved styrene resin is:

[0035] Step 1: Styrene resin surface treatment: add styrene resin to n-pentane foaming agent for foaming treatment, and then send it to a low-energy plasma processor for plasma treatment. The processing power is 2kW and the frequency is 20kHz;

[0036]Step 2: Preparation of nano-active liquid: Add cop...

Embodiment 2

[0047] A kind of self-insulating high-strength environment-friendly concrete of the present embodiment comprises the following raw materials in parts by weight:

[0048] 250 parts of cement, 100 parts of mineral powder, 65 parts of fine sand, 40 parts of fly ash, 25 parts of modified styrene resin, 20 parts of activated bentonite, 15 parts of interface agent, 10 parts of water reducing agent and 200 parts of deionized water; The particle size of mineral powder is 200 mesh; the particle size of fine sand is 1000 mesh; the particle size of fly ash is 100 mesh; the water reducer is sulfonated lignin water reducer;

[0049] The preparation method of described improved styrene resin is:

[0050] Step 1: Styrene resin surface treatment: Add styrene resin to n-pentane foaming agent for foaming treatment, and then send it to a low-energy plasma processor for plasma treatment. The processing power is 5kW and the frequency is 30kHz;

[0051] Step 2: Preparation of nano-active liquid: A...

Embodiment 3

[0062] A kind of self-insulating high-strength environment-friendly concrete of the present embodiment comprises the following raw materials in parts by weight:

[0063] 225 parts of cement, 75 parts of mineral powder, 60 parts of fine sand, 35 parts of fly ash, 20 parts of modified styrene resin, 15 parts of activated bentonite, 10 parts of interface agent, 7 parts of water reducing agent and 190 parts of deionized water; The particle size of mineral powder is 150 mesh; the particle size of fine sand is 750 mesh; the particle size of fly ash is 75 mesh; the water reducer is sulfonated lignin water reducer;

[0064] The preparation method of described improved styrene resin is:

[0065] Step 1: Styrene resin surface treatment: add styrene resin to n-pentane foaming agent for foaming treatment, and then send it to a low-energy plasma processor for plasma treatment. The processing power is 3.5kW and the frequency is 25kHz ;

[0066] Step 2: Preparation of nano-active liquid: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com