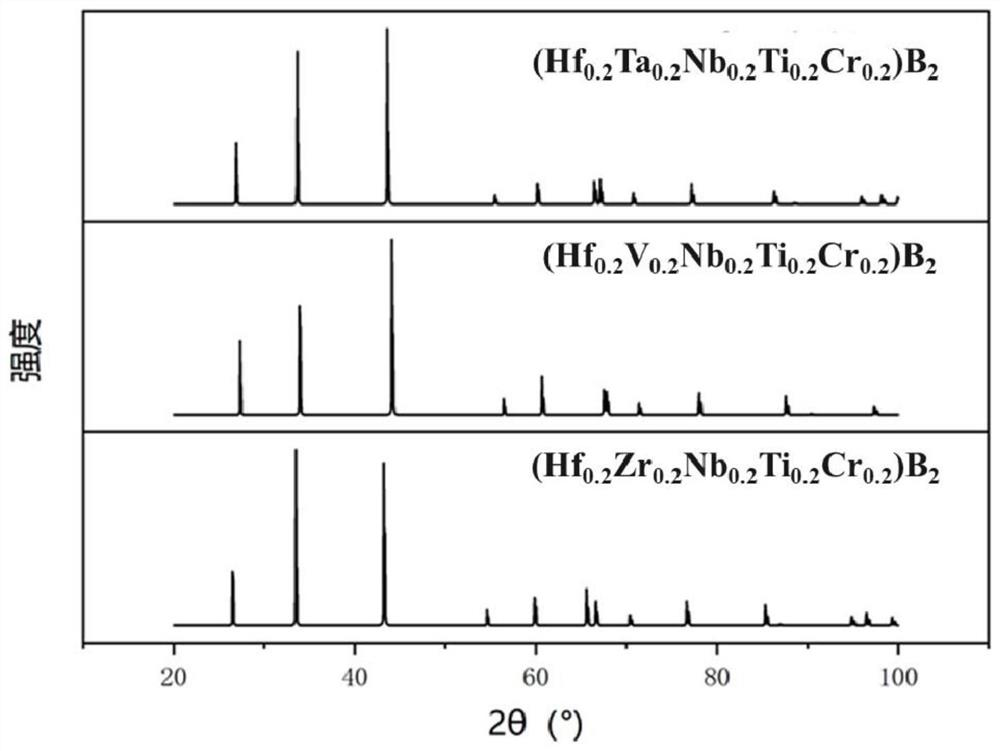

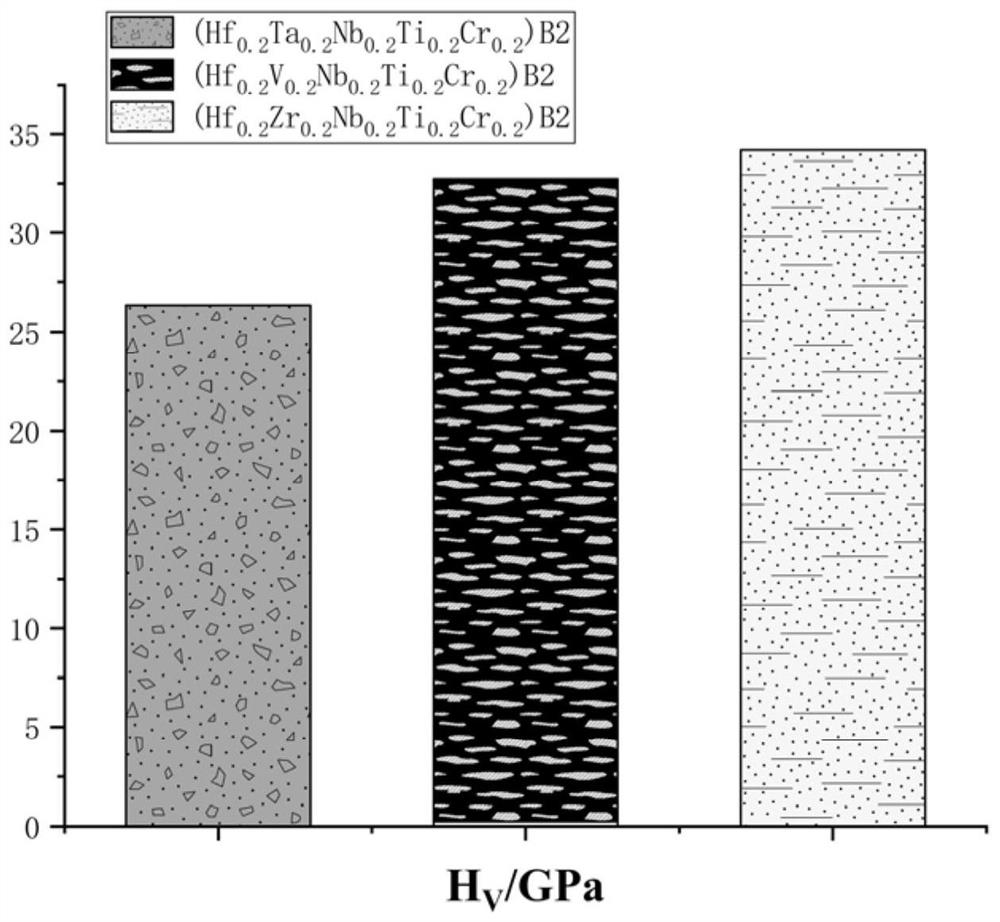

Ultrahigh-temperature high-entropy boride ceramic powder and preparation method thereof

A technology of ceramic powder and boride, which is applied in the field of ceramic materials to achieve the effects of low binding energy, reduced element segregation, and low enthalpy of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

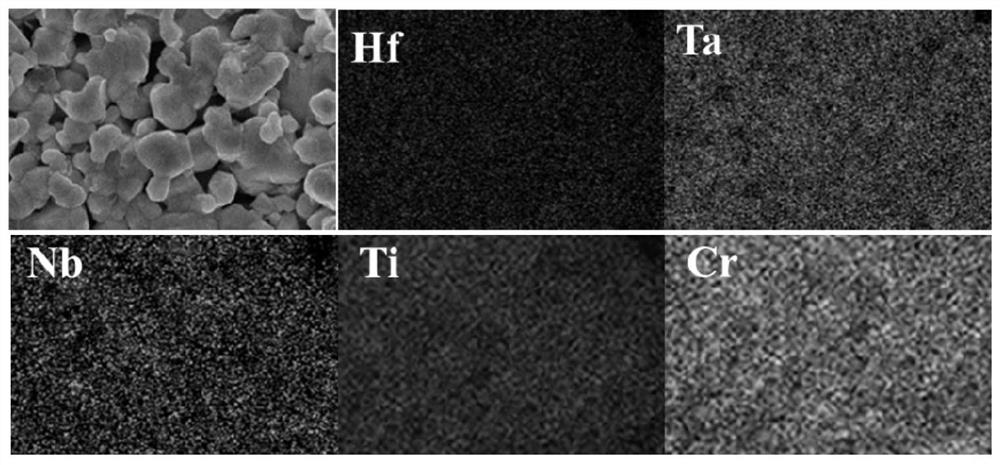

Embodiment 1

[0041] (1) HfB 2 、TiB 2 , CrB 2 、TaB 2 and NbB 2 Dosing according to the equimolar ratio of metal atoms and adding them to the ball mill tank, then adding deionized water, PVA and ball milling beads, the solid content is 40%, the mass fraction of PVA is 0.4%, the ball-to-material ratio is 4:1, at 250rpm Ball milled for 2 hours, mixed evenly to obtain slurry;

[0042] (2) agglomerating and granulating the slurry in step (1) by using a spray drying granulation tower, and passing the granulated powder through an inspection sieve to obtain an agglomerated powder with a particle size not greater than 70 μm;

[0043] Among them, the spray drying granulation parameters are: the inlet temperature is 250°C, the outlet temperature is 100°C, the nozzle speed is 30rpm, and the peristaltic pump speed is 25rpm;

[0044] (3) Utilize induction plasma spheroidization sintering equipment to carry out high-temperature sintering treatment to the agglomerated powder in step (2) for 5 times to...

Embodiment 2

[0052] (1) HfB 2 、TiB 2 , CrB 2 、TaB 2 and NbB 2 Dosing according to the equimolar ratio of metal atoms and adding them to the ball milling tank, then adding deionized water, PVA and ball milling beads, the solid content is 40%, the mass fraction of PVA is 0.4%, the ball-to-material ratio is 4:1, at 350rpm Ball milling for 4 hours, mixing evenly to obtain slurry;

[0053] (2) agglomerating and granulating the slurry in step (1) by using a spray drying granulation tower, and passing the granulated powder through an inspection sieve to obtain an agglomerated powder with a particle size not greater than 70 μm;

[0054] Among them, the spray drying granulation parameters are: the inlet temperature is 250°C, the outlet temperature is 100°C, the nozzle speed is 30rpm, and the peristaltic pump speed is 25rpm;

[0055] (3) Utilize induction plasma spheroidization sintering equipment to carry out high-temperature sintering treatment to the agglomerated powder in step (2) for 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com