Water spraying system and control method for heat treatment of metal plate and strip

A control method and metal strip technology, applied in heat treatment process control, heat treatment furnace, heat treatment equipment, etc., can solve the problems of low control precision, long adjustment time, low degree of automation, etc., and achieve high control accuracy, short adjustment time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

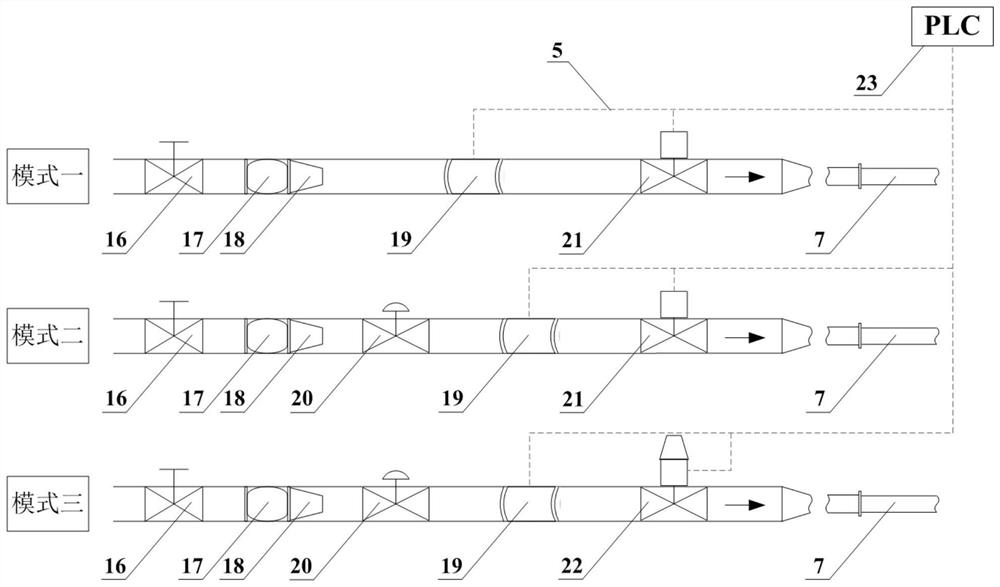

[0026] In this embodiment, taking the production mode (mode 1) of small batch, multi-specification, fast-paced and continuous quenching heat treatment of metal plate and strip within the specification range of 2-100mm thick, 1000-5000mm wide, and 4-26m long as an example, the metal Specific implementation plan of water spraying system and control method for plate and strip heat treatment:

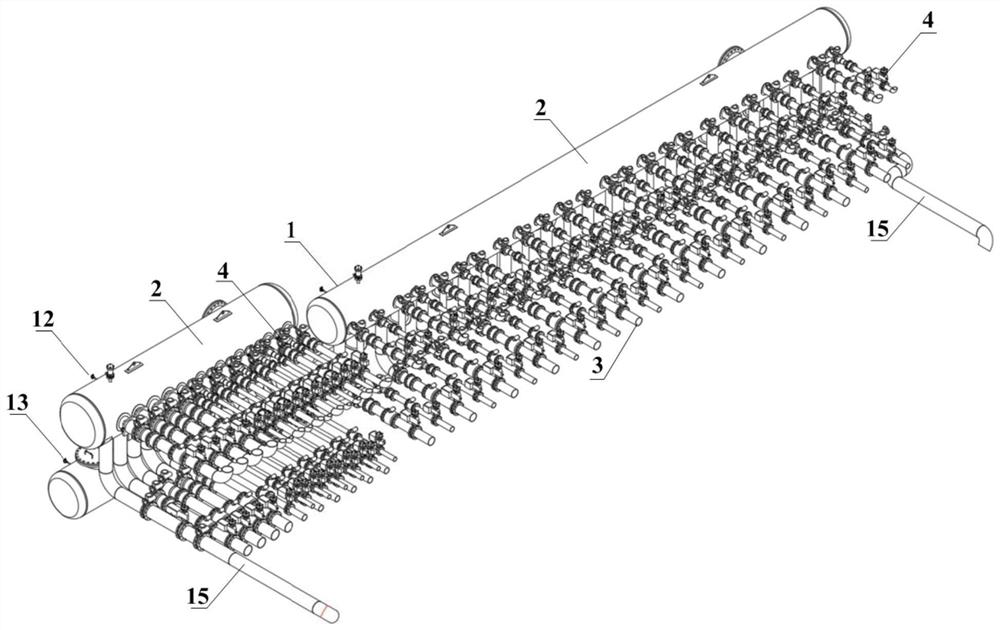

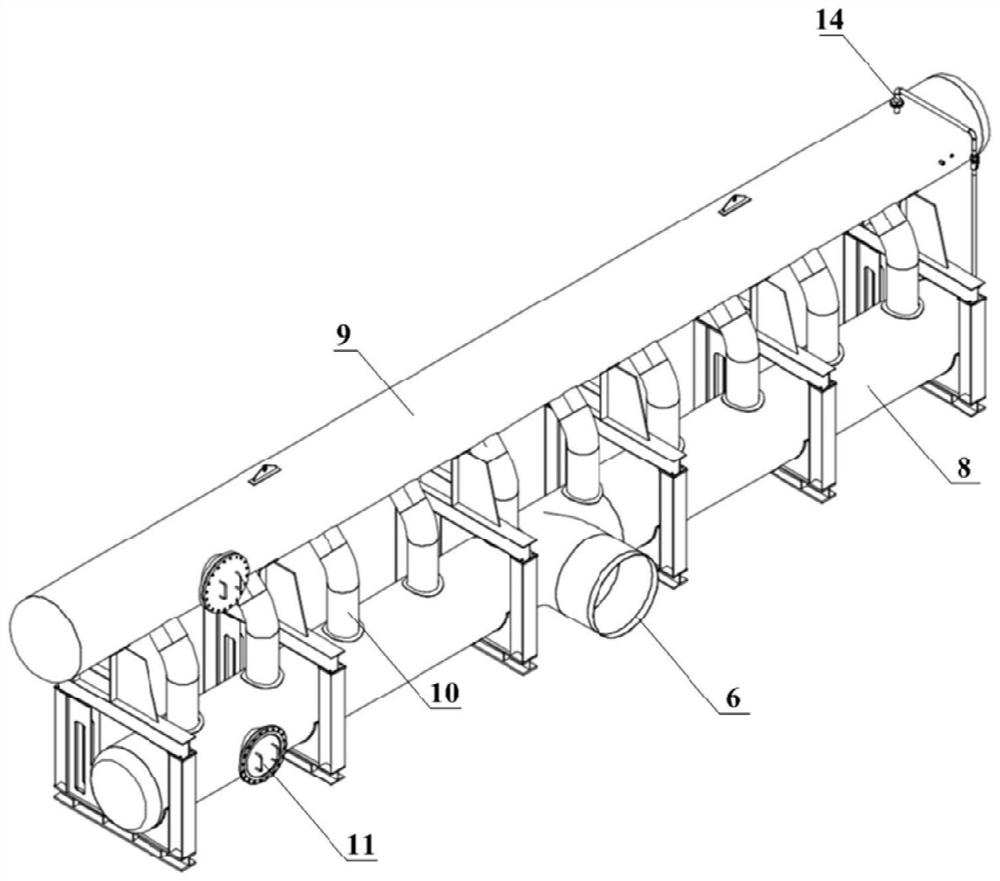

[0027] Such as Figure 1-3 As shown, when the water spray system 1 for the heat treatment of metal plates and strips does not receive the water spray signal, the cooling water with a certain flow rate, pressure and temperature enters the water inlet pipe 8 of the water diversion collector 2 from the main water supply pipeline 6, and passes through The intermediate pipeline 10 splits the flow and enters the water outlet pipeline 9, and the water pressure sensor 12 feeds back the actual water pressure to the control system 5PLC system 23, and the PLC system 23 controls the pneumatic bypass pi...

Embodiment 2

[0031] In this embodiment, the production mode (mode 3) of metal sheet and strip in the range of 2-100mm thick, 1000-5000mm wide, and 4-26m long in large batches, single specification, continuous quenching or mixed quenching / tempering heat treatment is taken as an example , to describe the specific implementation plan of the water spray system and control method for the heat treatment of metal plates and strips:

[0032] Such as Figure 1-3 As shown, when the water spray system 1 for the heat treatment of metal plates and strips does not receive a water spray signal, the embodiment is the same as that of the first embodiment. At this time, each sub-water supply pipeline 3 controls the pneumatic on-off valve 20 in the valve group 4 to close, the opening degree of the electric control valve 22 is maintained at the final opening degree when it was opened last time, and the maintenance valve 16 is opened, and each sub-water supply pipeline 3 to Jet nozzle 7 does not spray water. ...

Embodiment approach

[0037] Such as Figure 1-3 As shown, when the water spraying system 1 for the heat treatment of metal plates and strips is in a non-working state, the main water supply pipeline 6 stops water supply, the opening of the bypass pipeline 15 pneumatic control valve 21 is adjusted to the fully open position, and all sub-water supply pipelines 3 are overhauled The valve 16 is closed, and the cooling water in the diverter water collector 2 is emptied. Disassemble the conical filter 18, check the blockage and clean it up, dismantle the manhole 11 of the diverter water collector 2, check and clean up the internal impurities and blockage of the diverter water collector 2. Before putting into use again, the opening degree of the pneumatic regulating valve 21 of the bypass pipeline 15 is adjusted to the fully open position, all the sub-water supply pipelines 3 maintenance valves 16 are closed, and the exhaust pipeline 14 of the diversion water collector 2 is opened. Cooling water at high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com