High-entropy alloy coating and preparation method thereof

A high-entropy alloy and coating technology, which is applied in the field of laser surface modification of H13 steel, can solve problems such as poor bonding force between coating and substrate, poor wear resistance, and scrapping of perforating needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

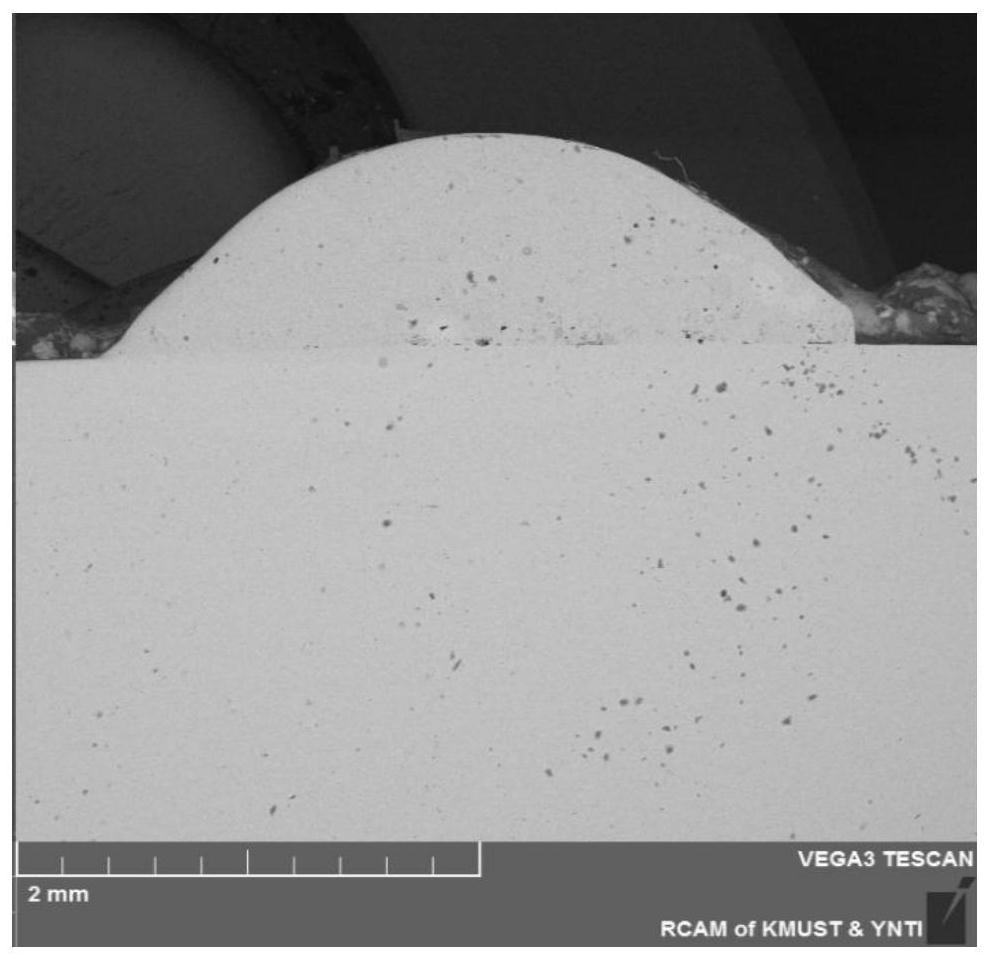

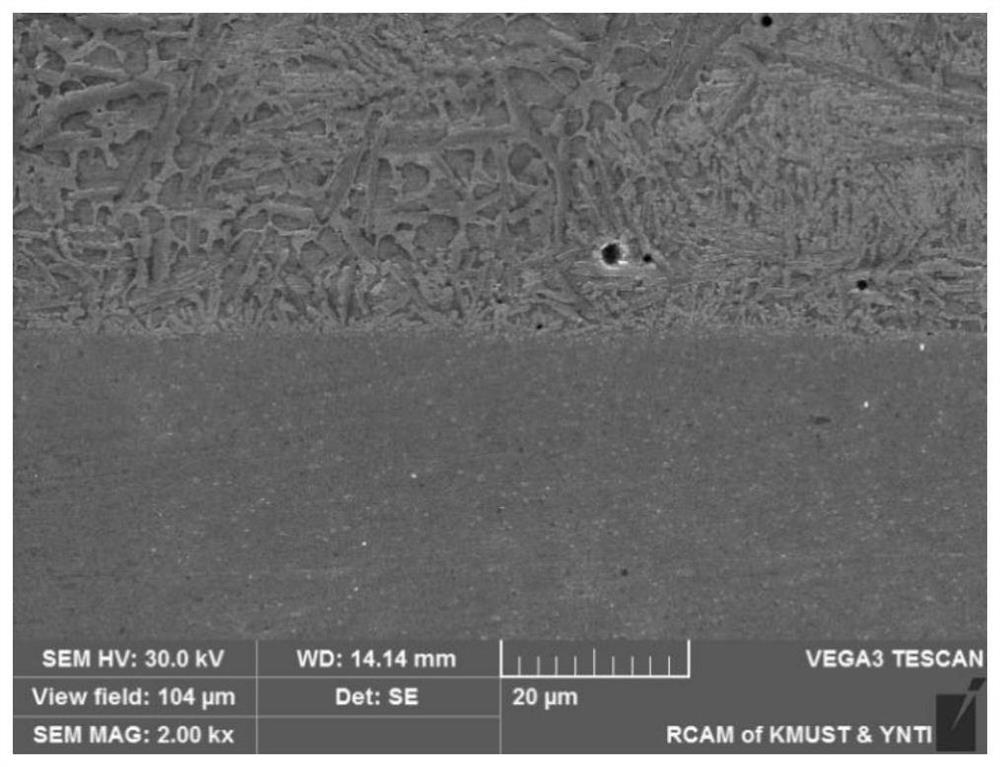

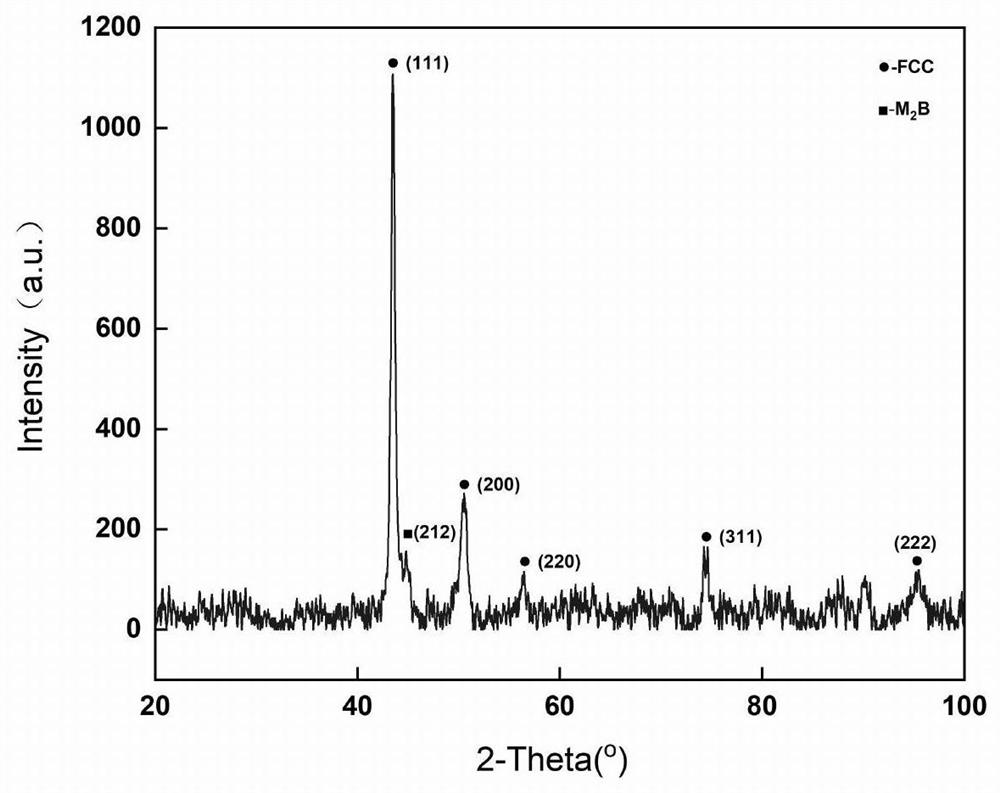

[0031] A CoCrFeMnNiB 0.8 The preparation method of high-entropy alloy coating specifically comprises the following steps:

[0032] (1) Grinding the substrate to remove the oxide layer, and then ultrasonically cleaning it with alcohol.

[0033] (2) Weigh Co, Cr, Fe, Mn, Ni and ferroboron metal powder according to the molar ratio of Co, Cr, Fe, Mn, Ni and boron as 1:1:1:1:1:0.8, and mix them evenly And carry out vacuum ball milling for more than 3h to obtain CoCrFeMnNiB 0.8 High entropy alloy powder.

[0034] (3) the CoCrFeMnNiB of step (2) 0.8 The high-entropy alloy powder is preset on the surface of the pretreated substrate to form a prefabricated layer, and then placed at a temperature of 80°C for 8 hours of constant temperature treatment. Laser cladding obtains a high-entropy alloy cladding layer. The laser power of the laser cladding is 4000W, and the scanning speed is It is 450mm / min, the spot diameter is 4.0mm, the defocus is 20mm, the protective gas is argon, and the...

Embodiment 2

[0042] A CoCrFeMnNiB 0.8The preparation method of high-entropy alloy coating specifically comprises the following steps:

[0043] (1) Grinding the substrate to remove the oxide layer, and then ultrasonically cleaning it with alcohol.

[0044] (2) Weigh Co, Cr, Fe, Mn, Ni and ferroboron metal powder according to the molar ratio of Co, Cr, Fe, Mn, Ni and boron as 1:1:1:1:1:0.8, and mix them evenly And carry out vacuum ball milling for more than 3h to obtain CoCrFeMnNiB 0.8 High entropy alloy powder.

[0045] (3) the CoCrFeMnNiB of step (2) 0.8 The high-entropy alloy powder is preset on the surface of the pretreated substrate to form a prefabricated layer, and then placed at a temperature of 60°C for 6 hours of constant temperature treatment. Laser cladding obtains a high-entropy alloy cladding layer. The laser power of the laser cladding is 3700W, and the scanning speed is It is 350mm / min, the spot diameter is 5.0mm, the defocus is 15mm, the protective gas is argon, and the ...

Embodiment 3

[0047] A CoCrFeMnNiB 0.8 The preparation method of high-entropy alloy coating specifically comprises the following steps:

[0048] (1) Grinding the substrate to remove the oxide layer, and then ultrasonically cleaning it with alcohol.

[0049] (2) Weigh Co, Cr, Fe, Mn, Ni and ferroboron metal powder according to the molar ratio of Co, Cr, Fe, Mn, Ni and boron as 1:1:1:1:1:0.8, and mix them evenly And carry out vacuum ball milling for more than 3h to obtain CoCrFeMnNiB 0.8 High entropy alloy powder.

[0050] (3) the CoCrFeMnNiB of step (2) 0.8 The high-entropy alloy powder is preset on the surface of the pretreated substrate to form a prefabricated layer, and then placed at a temperature of 100°C for 10 hours of constant temperature treatment, and the high-entropy alloy cladding layer is obtained by laser cladding. The laser power of the laser cladding is 4200W, and the scanning speed is It is 500mm / min, the spot diameter is 3.0mm, the defocus is 30mm, the protective gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness value | aaaaa | aaaaa |

| Average hardness value | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com