Preparation process of high-linoleic-acid antioxidant powdered oil

A technology of powdered oil and high linoleic acid, applied in edible oil/fat, food science, application, etc., can solve problems such as temperature rise, unsuitable microencapsulation of heat-sensitive materials, fast drying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

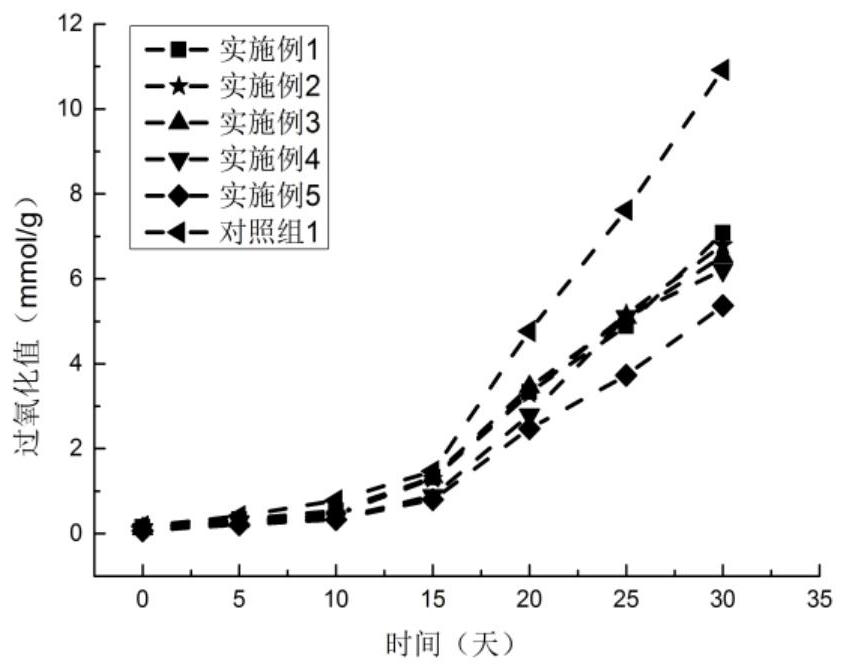

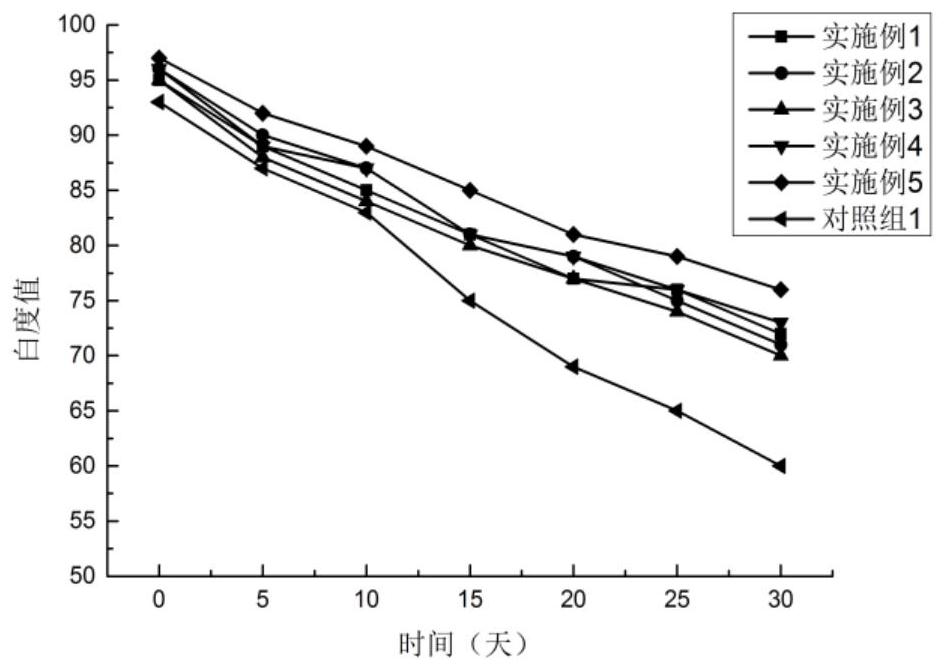

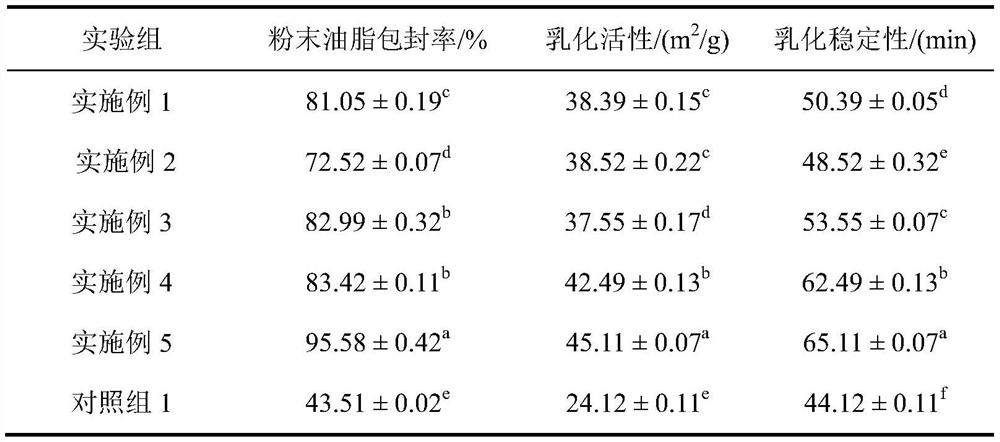

[0019] A preparation process of high linoleic acid anti-oxidation powder oil, characterized in that the method comprises the following steps: (1) preparation of glycosylated protein: Weigh soybean protein isolate (purity ≥ 92%) and dextran (70KDa) respectively Soybean protein isolate solution and 0.5-2.0% (w / v) dextran solution, soybean The isolated protein solution and the dextran solution were mixed at a volume ratio of 3:1-1:2, stirred and homogenized, fully hydrated overnight (12-16h) in a refrigerator at 4°C, then freeze-dried and stored at a humidity of 79%, 60 React at ℃ for 12 hours to obtain glycosylated protein; (2) Emulsion preparation: prepare a glycosylated protein solution (phosphate buffer solution 0.1M, pH 7.0) with a mass fraction of 3.0-5.0% (w / v), stir at room temperature for 12 hours to fully Dissolve, then add the mass concentration of 1.5-3.0% (w / v) gallocatechin and the mass concentration of 1.0-2.5% (w / v) conjugated linoleic acid respectively, use a hig...

Embodiment 1

[0024] A preparation process of high linoleic acid anti-oxidation powder oil, characterized in that the method comprises the following steps: (1) preparation of glycosylated protein: Weigh soybean protein isolate (purity ≥ 92%) and dextran (70KDa) respectively Soy protein isolate solution and mass fraction of 0.5% (w / v) dextran solution, soybean protein isolate solution and The dextran solution was mixed at a volume ratio of 3:1, stirred homogeneously, fully hydrated in a refrigerator at 4°C overnight (12-16h), then freeze-dried and reacted at a humidity of 79% and 60°C for 12h to obtain glycosylated protein ; (2) Emulsion preparation: configure the glycated protein solution with a mass fraction of 3.0% (w / v) (phosphate buffer solution 0.1M, pH 7.0), stir at room temperature for 12 hours to fully dissolve it, and then add a mass concentration of 1.5 % (w / v) gallocatechin and mass concentration are 1.0% (w / v) conjugated linoleic acid, use high-speed shearing machine to emulsify...

Embodiment 2

[0026]A preparation process of high linoleic acid anti-oxidation powder oil, characterized in that the method comprises the following steps: (1) preparation of glycosylated protein: Weigh soybean protein isolate (purity ≥ 92%) and dextran (70KDa) respectively Soy protein isolate solution and mass fraction of 2.0% (w / v) dextran solution, soybean protein isolate solution and The dextran solution was mixed at a volume ratio of 1:2, stirred homogeneously, fully hydrated in a refrigerator at 4°C overnight (12-16h), then freeze-dried and reacted at a humidity of 79% and 60°C for 12h to obtain glycosylated protein ; (2) Emulsion preparation: configure a glycosylated protein solution (phosphate buffer solution 0.1M, pH 7.0) with a mass fraction of 5.0% (w / v), stir at room temperature for 12 hours to fully dissolve it, and then add % (w / v) gallocatechin and mass concentration are 2.5% (w / v) conjugated linoleic acid, use high-speed shearing machine to emulsify at 12000r / min rotating spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com