Production process of high-yield and high-ester catechin green tea extract

A technology of green tea extract and production process, which is applied in the field of food processing, can solve the problems of complex operation and low catechin content, and achieve the effects of high biological activity, good process application prospect and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 200g of crushed green tea raw material, add 2L of hot water at 100°C for 1 hour for extraction, filter, add 1.6L of hot water for extraction at 100°C for one hour, filter, and combine the two filtrates for later use; take 200ml of macroporous resin AB-8 for packaging For the column, wash the resin with 50% ethanol, then wash it with a large amount of water until there is no alcohol smell, and set it aside; take 2.5L of the mixed feed solution and put it on the column, control the flow rate to 2BV / h, and use 500ml Rinse with water, and then elute with 1L of 80% ethanol; after the end, concentrate the alcohol lotion into an extract, add ethyl acetate for extraction, shake it fully, let it stand, separate layers, concentrate and dry the ester layer, and obtain the finished dry powder. Detecting the component content and calculating the yield in the finished product dry powder obtained, EGCG55%, total catechin 82%, ester type catechin 67%, yield 72%.

Embodiment 2

[0035] Take 200kg of crushed green tea raw materials, add 2000L hot water at 100°C for 1 hour to extract, filter, add 1600L of hot water to extract at 100°C for one hour, filter, filter, and filter the two filtrates, then filter them with a plate and frame, and set aside; take macroporous resin AB- 8. Pack the column, wash the resin with 50% ethanol, and then wash it with a large amount of water until there is no alcohol smell, and set it aside; take the material liquid from the plate frame and put it on the column, control the flow rate to 2BV / h, after the end of the column Rinse with a large amount of water, and then elute with 80% ethanol; after the end, concentrate the alcohol washing solution into an extract, add three times of ethyl acetate for extraction, let stand for 60±20min, and separate layers; the organic layer enters The concentrator concentrates according to the standard operating procedure of the double-effect concentrator, the temperature is controlled to be le...

Embodiment 3

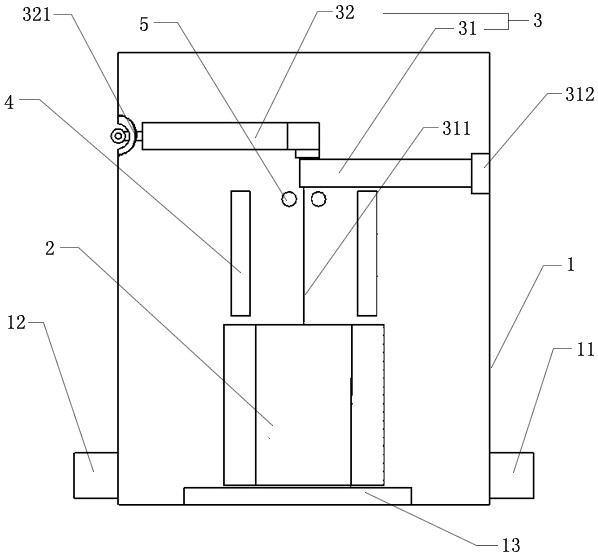

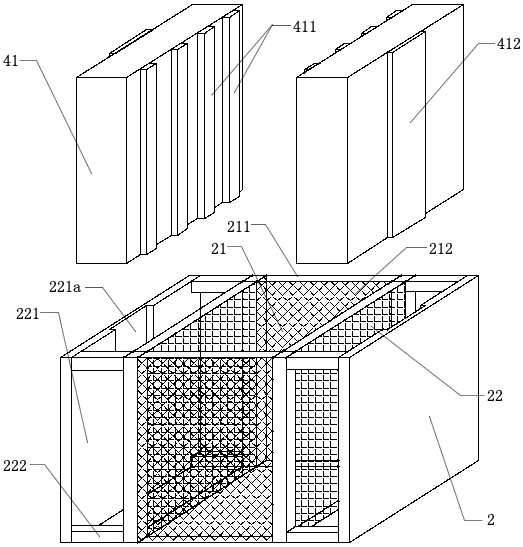

[0038] as attached figure 1As shown, an integrated leaching and filtering device includes a body 1 and a container 2 for placing tea leaves. The body 1 is respectively provided with a liquid inlet 11 and a liquid outlet 12. The closed door 13 on the body 1 enters into the body 1 or moves out from the body 1; the upper end of the housing device 2 in the body 1 is provided with a lifter for lifting the housing device 2. A unit 3, and a compression unit 4 for compressing the accommodating device 2. The lifting unit 3 includes a lifting plate 31 with one end fixed on the inner wall of the body 1 by a torsion spring 312. A traction rope 311 is fixed on the lower side of the lifting plate 31 away from the fixed end. The lower end of the traction rope 311 is provided with a hook or other fixing device (Fig. not marked in ), which can be used to fix the accommodating device 2. In addition, a control board 32 is provided to adjust the lifting height of the lifting board 31. One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com