Whitening composition and preparation method thereof

A composition and whitening technology, which can be used in pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., and can solve the problem of single types of whitening active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0224] In terms of mass percentage:

[0225] Stir and dissolve 0.5% phenylethylresorcinol, 1% caprylic capric triglyceride, 1% sodium stearoyl lactylate, and 0.1% butyl hydroxyanisole in a water bath at 40°C to obtain an oil phase ,spare;

[0226] Stir and dissolve 5% carnosine, 10% nicotinamide, 30% white truffle extract, 10% Morus alba extract and 22.4% water in a water bath at a temperature of 40°C to obtain an aqueous phase for later use;

[0227] After the oil phase and the water phase were obtained, the oil phase was added dropwise to the water phase at a rate of 2 drops / second in a water bath at 40°C. During the dropping process, the stirring rate was controlled at 600 rpm. After the mixing was completed, 10% ethyl alcohol was added. Oxydiglycol and 10% glycerin were emulsified under high-speed shear at 5000 rpm for 10 min to make a micron-sized dispersion.

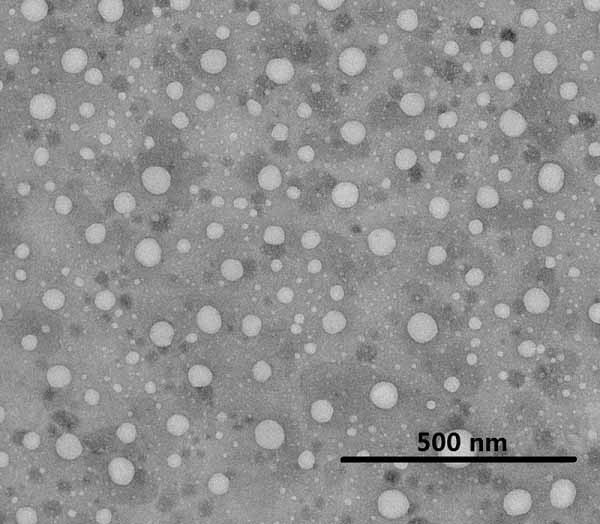

[0228] The micron-sized dispersion was subjected to high-pressure homogenization treatment at a pressure of 16...

Embodiment 2

[0231] In terms of mass percentage:

[0232] 5% phenylethyl resorcinol, 5% isopropyl palmitate, 5% PEG-8 caprylic / capric glycerides, 10% tribehenyl PEG-20 esters, 0.3% butylated hydroxytoluene at temperature Stir and dissolve in a water bath at 50°C to obtain an oil phase for later use;

[0233] Stir and dissolve 2% carnosine, 20% nicotinamide, 10% white truffle extract, 0.5% Morus alba extract and 27.2% water in a water bath at a temperature of 50°C to obtain an aqueous phase for later use;

[0234] After the oil phase and water phase were obtained, the oil phase was added dropwise to the water phase at a rate of 6 drops / second in a water bath at 50°C, and the stirring rate was controlled at 500 rpm during the dropping process. After mixing, 5% propylene glycol was added , 10% octyldodecanol, high-speed shear emulsification at 6000 rpm for 3 min to make a micron-sized dispersion.

[0235] The micron-scale dispersion was subjected to high-pressure homogenization treatment at...

Embodiment 3

[0238] In terms of mass percentage:

[0239] 12% phenylethyl resorcinol, 15% isopropyl palmitate, 5% polyoxyethylene sorbitan fatty acid ester, 10% polyoxyethylene hydrogenated castor oil, 5% cocoyl glucoside, 2 % Vitamin E acetate was stirred and dissolved in a water bath at a temperature of 55°C to obtain an oil phase for subsequent use;

[0240] Stir and dissolve 0.8% carnosine, 6% nicotinamide, 5% white truffle extract, 10% Morus alba extract and 19.2% water in a water bath at a temperature of 55°C to obtain an aqueous phase for later use;

[0241] After the oil phase and the water phase are obtained, add the oil phase to the water phase at a rate of 5 drops / second in a water bath at 55°C. During the dropping process, the stirring rate is controlled at 900 rpm. After the mixing is completed, add 10% PPG -26-butanol-26, high-speed shear emulsification at 7000 rpm for 6 min to make a micron-scale dispersion.

[0242] The micron-scale dispersion was subjected to high-pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com