Novel bifunctional group mixed mode organic polymer monolithic column, and preparation method and application thereof

A mixed-mode, monolithic column technology, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of limited application range, insufficient selection of substances to be separated, and single mode, so as to expand the application range, Excellent reverse chromatography retention performance, good permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Capillary pretreatment: First, take a certain length of empty quartz capillary column with an inner diameter of 50 μm, use 1.0M NaOH solution to wash the capillary for 20 minutes, and use deionized water to wash it to neutral; thirdly, use 0.4M HCl solution for alkaline The pretreated capillary was rinsed for 20 min, then rinsed with deionized water until neutral; finally, rinsed with methanol solution for 10 min, and then rinsed with N 2 Blow dry; use the above process to pretreat the four quartz capillary empty columns respectively, and set aside.

Embodiment 2

[0031] Vinylation of the inner wall of the capillary: use 50% volume concentration of methacryloxypropyltriethoxysilane as the solute and methanol as the solvent to carry out the pretreatment of the four quartz capillary empty columns in Example 1, respectively. treatment, and use a Teflon tube (Teflon tube) to connect the two ends of the quartz capillary to form a ring, place it in a water bath with a preset temperature of 45°C and heat it at a constant temperature for 18 hours to vinylize the inner wall of the quartz capillary; then, wash it with methanol for 20 minutes Remove the unreacted silane reagent, then use N 2 Blow dry; get four vinylized quartz capillary empty columns, spare;

Embodiment 3

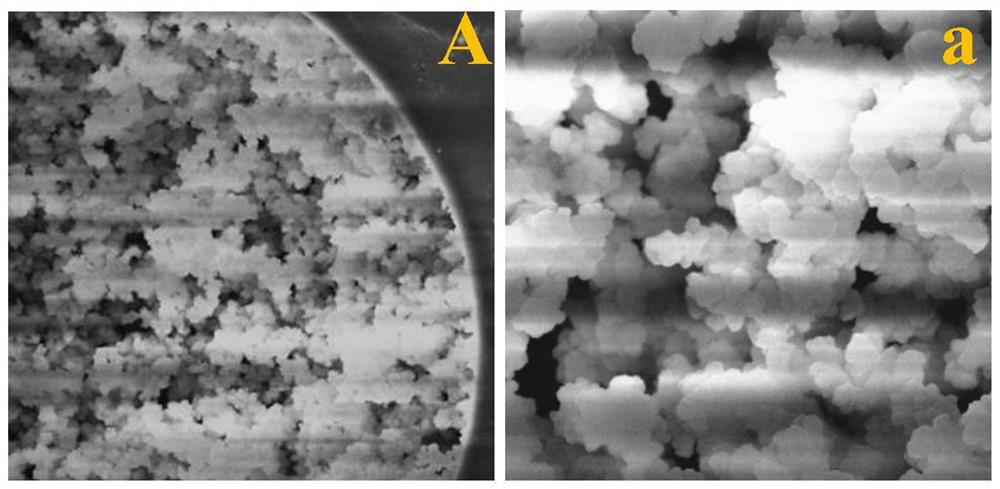

[0033] Quartz capillary monolithic column preparation: 3.8% (w / w) of 4-vinylbiphenyl, 2.2% (w / w) of N,N,N-trimethylvinylbenzyl ammonium chloride, 9.0% ( w / w) of ethylene glycol dimethacrylate, 42.5% (w / w) of cyclohexanol, 42.5% (w / w) of dodecanol and 1.5% of 4-vinylbiphenyl, N, Azobisisobutyronitrile of the total mass of N,N-trimethylvinylbenzyl ammonium chloride and ethylene glycol dimethacrylate is placed in an Eppendorf centrifuge tube (eppendorf tube) for ultrasonic mixing, and removed Bubbles; inject the polymer solution obtained above into one of the vinylation-modified quartz capillaries in Example 2, control the injection length at 25.5 cm, and heat at a constant temperature in a water bath with a preset temperature of 65°C for 24 hours; rinse with methanol The above-mentioned quartz capillary removes unreacted monomers and porogens to obtain a monolithic column of bifunctional group mixed-mode organic polymers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com