Preparation method of 3D printed mullite automobile exhaust purification catalyst carrier

A technology for purifying catalysts and 3D printing, applied in catalyst carriers, catalyst carriers, physical/chemical process catalysts, etc., can solve the problems of small specific surface area, poor thermal stability, low strength, etc., to improve specific surface area, good catalytic effect, The effect of strong thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

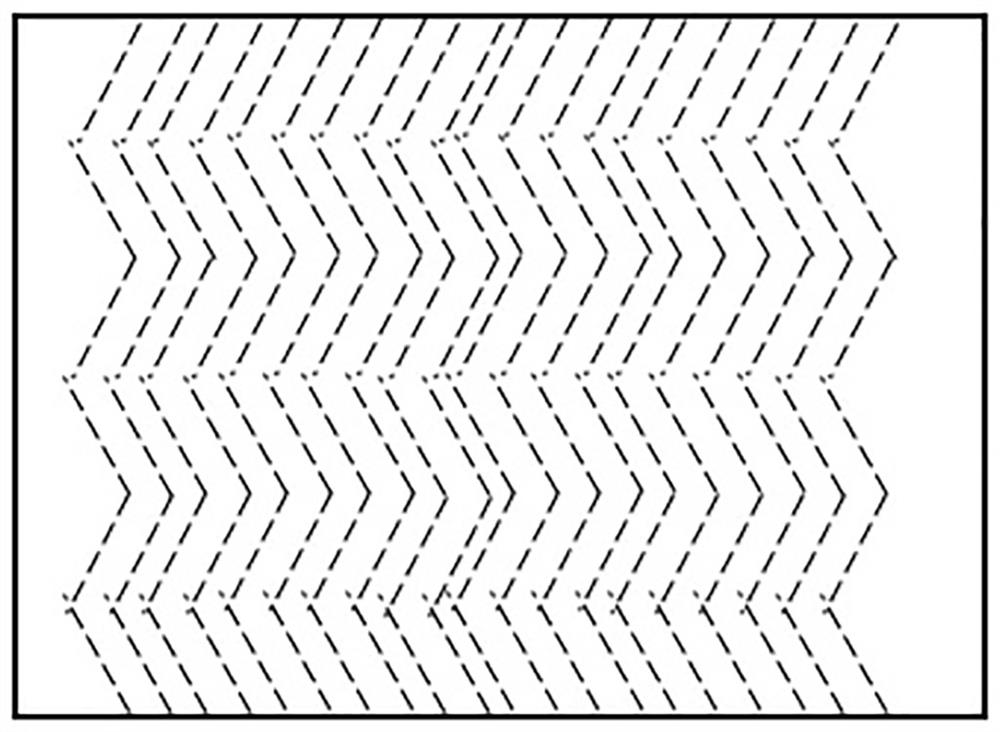

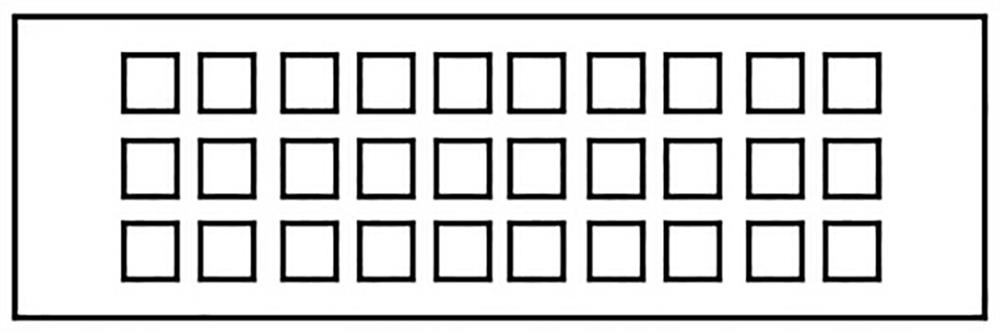

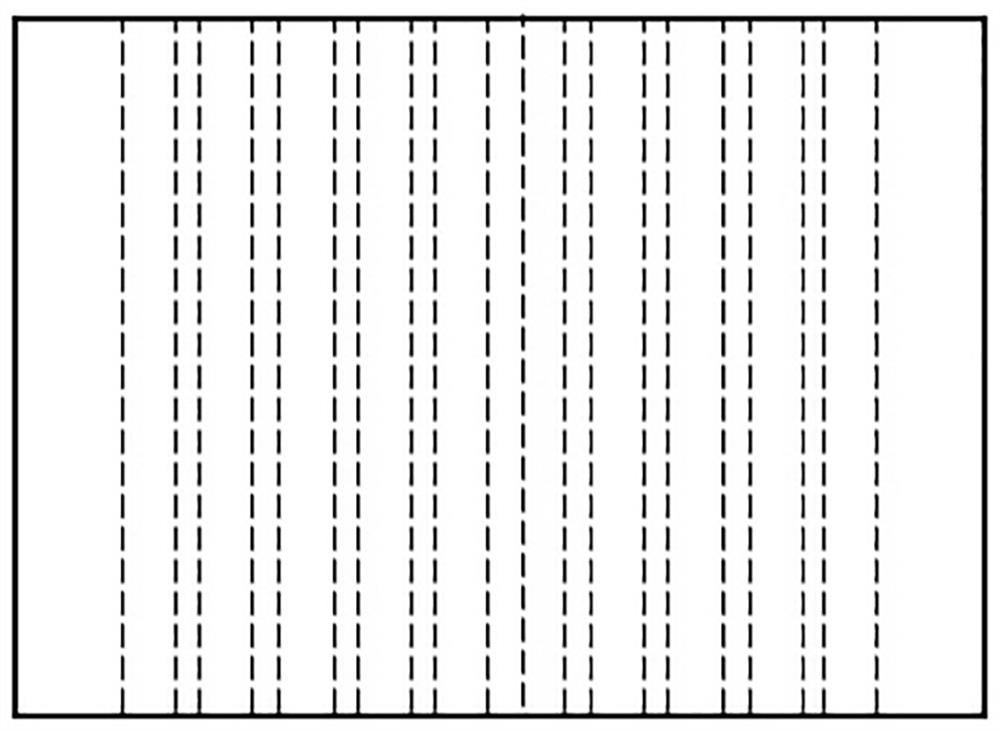

[0024] Put 150g of kaolin and 350g of alumina powder in a ball mill jar, use 500g of water as the ball milling medium, and mill for 8 hours to obtain an aluminum-silicon suspension; cut 100g of mullite fiber cotton into a sample with a length of 10mm, a width of 5mm, and a height of 5mm Then mix the sample with 500g of water and put it into the crusher to crush for 25s to obtain the mullite fiber suspension; pour the aluminum-silicon suspension and the mullite fiber suspension into the mixer to Stir at 200r / min for 10min to obtain a mixed slurry; put the mixed slurry into a suction filter funnel, turn on the vacuum pump and filter for 5h; put the filtered mixed slurry into a double-rotary blade mixer and knead for 2h , Aluminosilicate mud with mullite fibers must be added; use SolidWorks software to create a three-dimensional model of the catalyst carrier for automobile exhaust purification; use Simplify 3D software to slice the created three-dimensional model of the catalyst c...

Embodiment 2

[0027] Put 240g of kaolin and 360g of alumina powder in a ball mill jar, use 800g of water as the ball milling medium, and mill for 8 hours to obtain an aluminum-silicon suspension; cut 50g of mullite fiber cotton into a sample with a length of 10mm, a width of 5mm, and a height of 5mm Then mix the sample with 500g of water and put it into the crusher to crush for 20s to obtain the mullite fiber suspension; pour the aluminum-silicon suspension and the mullite fiber suspension into the mixer to Stir at 200r / min for 10min to obtain a mixed slurry; put the mixed slurry into a suction filter funnel, turn on the vacuum pump and filter for 5h; put the filtered mixed slurry into a double-rotary blade mixer and knead for 2h , Aluminosilicate mud with mullite fibers must be added; use SolidWorks software to create a 3D model of the catalyst carrier for automobile exhaust purification; use Simplify 3D software to slice the created 3D model of the catalyst carrier for automobile exhaust p...

Embodiment 3

[0030] Put 120g of kaolin and 270g of alumina powder in a ball mill jar, use 400g of water as the ball milling medium, and mill for 8 hours to obtain an aluminum-silicon suspension; cut 80g of mullite fiber cotton into a sample with a length of 10mm, a width of 5mm, and a height of 5mm Then mix the sample with 500g of water and put it into the crusher to crush for 20s to obtain the mullite fiber suspension; pour the aluminum-silicon suspension and the mullite fiber suspension into the mixer to Stir at 200r / min for 10min to obtain a mixed slurry; put the mixed slurry into a suction filter funnel, turn on the vacuum pump and filter for 5h; put the filtered mixed slurry into a double-rotary blade mixer and knead for 2h , Aluminosilicate mud with mullite fibers must be added; use SolidWorks software to create a three-dimensional model of the catalyst carrier for automobile exhaust purification; use Simplify 3D software to slice the created three-dimensional model of the catalyst ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com