Method for repairing combined polluted soil and equipment system therefor

A compound pollution and soil technology, applied in the restoration of polluted soil, etc., can solve the problems of days or even months, the inability to realize the treatment of heavy metal ions, and the need to improve the repair rate. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

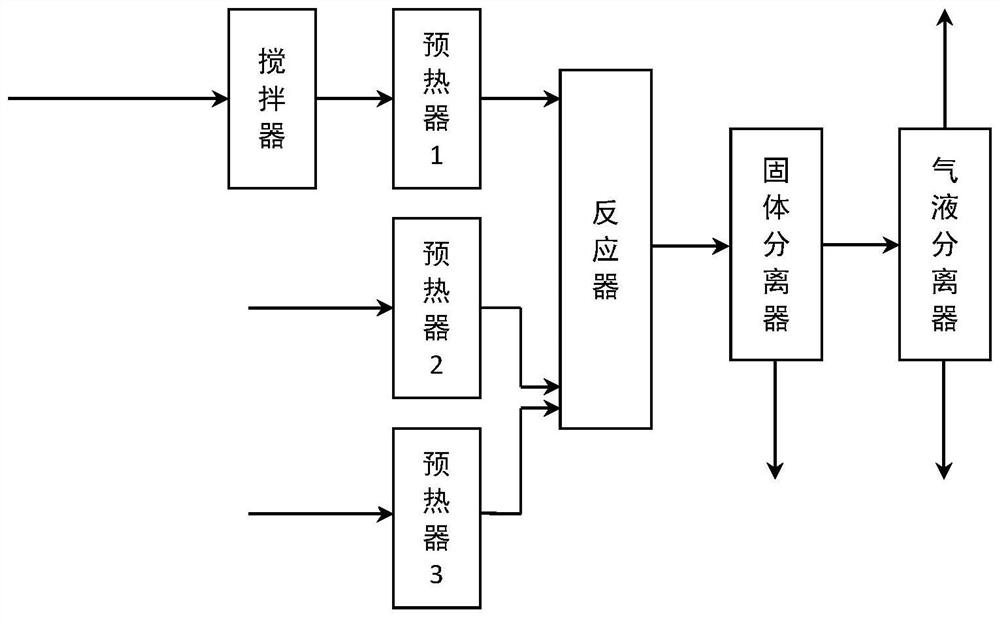

[0042] Such as figure 1 As shown, the petroleum hydrocarbon-heavy metal compound polluted soil was remediated according to the following steps:

[0043] (1) Mixing of solid materials: Add the composite polluted soil containing petroleum hydrocarbons and heavy metals Cd and Cu, solid catalyst TiO2, and solid passivator hydrocalumite to the agitator in a ratio of 1:0.2:0.4 to start stirring, so that its uniform mixing;

[0044] (2) Material preheating: Add the uniformly mixed solid material to preheater 1 to preheat to 300°C, add water to preheater 2 to preheat to 300°C, and simultaneously add oxidant to preheater Preheat to 300°C in container 3;

[0045] (3) Material sampling: the preheated solid material is added to the reactor from the upper end, the preheated water is added to the reactor from the lower end synchronously, and the preheated oxidant is added to the reactor from the lower end synchronously;

[0046] (4) Synergistic passivation reaction of hydrothermal cataly...

Embodiment 2

[0052] Such as figure 1 As shown, the PCB-heavy metal compound polluted soil was remediated according to the following steps:

[0053] (1) Mixing of solid materials: Add composite contaminated soil containing polychlorinated biphenyls and heavy metals Pb and Zn, solid catalyst Al2O3, and solid passivator sepiolite to the agitator at a ratio of 1:0.05:0.5 to start stirring, make it evenly mixed;

[0054] (2) Material preheating: put the mixed solid material into the preheater 1 to preheat to 150°C, add water to the preheater 2 to preheat to 150°C, and simultaneously add the oxidant to the preheater Preheat to 150°C in container 3;

[0055] (3) Material sampling: the preheated solid material is added to the reactor from the upper end, the preheated water is added to the reactor from the lower end synchronously, and the preheated oxidant is added to the reactor from the lower end synchronously;

[0056] (4) Synergistic passivation reaction of hydrothermal catalytic oxidation: ...

Embodiment 3

[0062] Such as figure 1 As shown, the polycyclic aromatic hydrocarbons-heavy metal compound polluted soil was remediated according to the following steps:

[0063] (1) Mixing of solid materials: Add the composite polluted soil containing polycyclic aromatic hydrocarbons and heavy metals Cd and Pb, solid catalyst TiO2, and solid passivator sepiolite to the agitator in a ratio of 1:0.3:0.05 to start stirring, so that its uniform mixing;

[0064] (2) Material preheating: Add the uniformly mixed solid material to preheater 1 to preheat to 400°C, add water to preheater 2 to preheat to 400°C, and simultaneously add oxidant to the preheater Preheat to 400°C in container 3;

[0065] (3) Material sampling: the preheated solid material is added to the reactor from the upper end, the preheated water is added to the reactor from the lower end synchronously, and the preheated oxidant is added to the reactor from the lower end synchronously;

[0066] (4) Synergistic passivation reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com