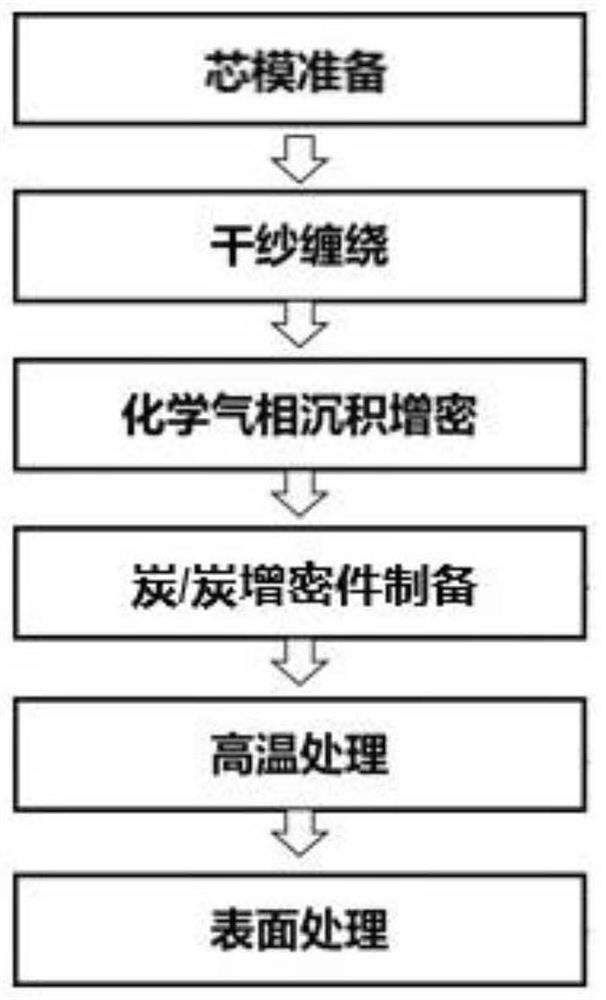

A kind of preparation method of winding high-strength and high-purity carbon/carbon composite material rotor

A carbon composite material and winding molding technology, which is applied in the field of preparing high-strength and high-purity carbon/carbon composite material rotors by winding, can solve the problems of long preparation cycle, complicated process, and difficulty in achieving high purity, and achieves shortening production cycle, The production process is simple and the effect of avoiding the phenomenon of surface crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

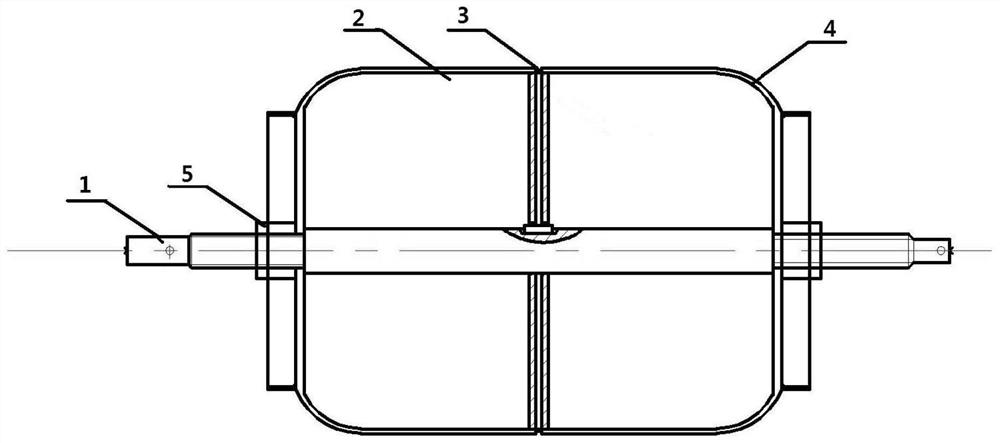

[0042] Step 1. Mandrel preparation: use graphite as raw material to prepare a mandrel as a winding tool; the outer surface structure and size of the mandrel are similar to the inner surface structure and size of the target product carbon / carbon composite material revolving body, the specific The schematic diagram of the winding tooling structure is as follows: figure 2 As shown, the mandrel includes a straight cylinder section 2 and a head section 4 arranged at the end of the straight cylinder section 2. Fasteners 5 are arranged on the outside of the head section 4, and every two mandrel molds are symmetrically arranged on the mandrel 1. The two fasteners 5 are linked with the mandrel 1, and there is a processing reserved seam 3 between the two mandrels to protect the mandrel from being damaged when the two mandrels are machined and separated. The straight section 2 of the mandrel is The outer diameter is 633mm, and the ...

Embodiment 2

[0051] This embodiment includes the following steps:

[0052] Step 1. Mandrel preparation: use graphite as raw material to prepare a mandrel as a winding tool; the outer surface structure and size of the mandrel are similar to the inner surface structure and size of the target product carbon / carbon composite material revolving body, the specific The schematic diagram of the winding tooling structure is as follows: figure 2 As shown, the mandrel includes a straight cylinder section 2 and a head section 4 arranged at the end of the straight cylinder section 2. Fasteners 5 are arranged on the outside of the head section 4, and every two mandrel molds are symmetrically arranged on the mandrel 1. The two fasteners 5 are linked with the mandrel 1, and there is a processing reserved seam 3 between the two mandrels to protect the mandrel from being damaged when the two mandrels are machined and separated. The straight section 2 of the mandrel is The outer diameter is 621mm, and the ...

Embodiment 3

[0061] This embodiment includes the following steps:

[0062] Step 1. Mandrel preparation: use graphite as raw material to prepare a mandrel as a winding tool; the outer surface structure and size of the mandrel are similar to the inner surface structure and size of the target product carbon / carbon composite material revolving body, the specific The schematic diagram of the winding tooling structure is as follows: Figure 5As shown, the mandrel includes a straight cylinder section 2, which is supported by a support plate, and is fixed on the mandrel 1 by a fastener 5 to be linked with the mandrel 1, and the outer diameter of the straight cylinder section 2 of the mandrel is 377.6 mm;

[0063] Step 2. Dry yarn winding: install the mandrel prepared in step 1 on the winding machine and link with the mandrel through the card slot, and lay a single layer of graphite paper evenly and tightly on the surface of the mandrel as a release layer, in which the single layer of graphite The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com