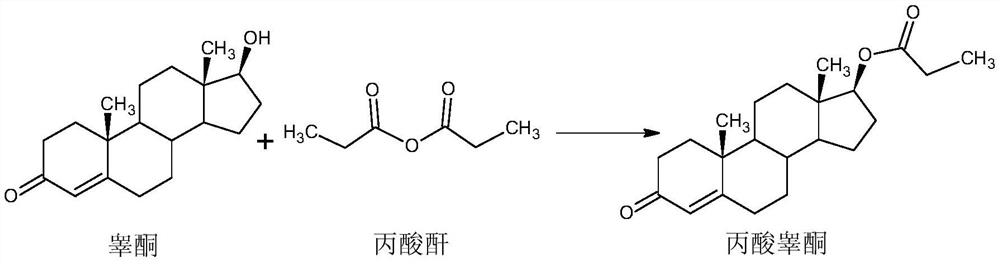

Preparation method of testosterone propionatete

A technology of testosterone propionate and propionic anhydride, which is applied in the field of drug preparation, can solve the problems of low yield, large impurities, and large waste water, and achieve the effects of high purity, high product quality and yield, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

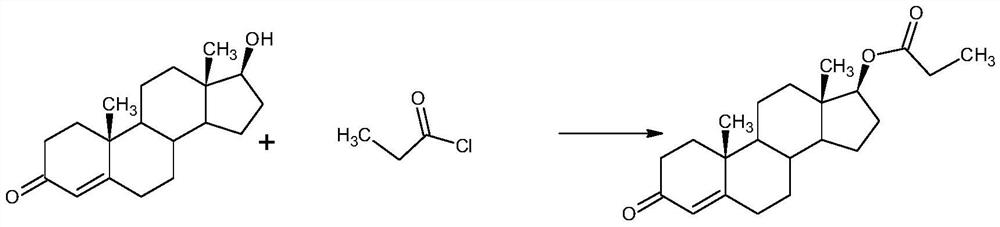

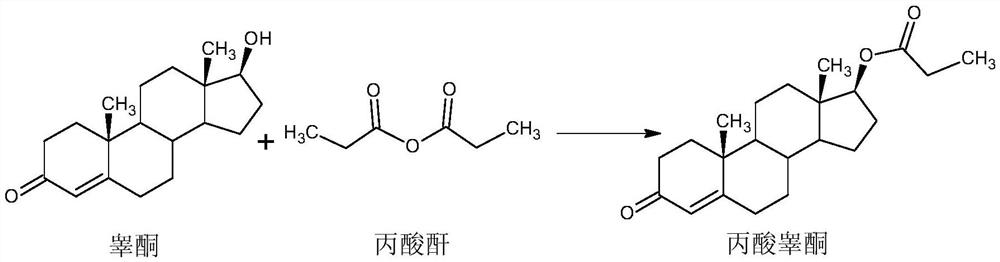

Method used

Image

Examples

example 1

[0021] The preparation of example 1 testosterone propionate

[0022] Under nitrogen atmosphere, put 10g of testosterone (17β-hydroxyandrost-4-en-3-one) into 10ml of dichloromethane, add 1ml of pyridine, 5g of 4-dimethylaminopyridine (DMAP), add 10ml of propionic anhydride , keep warm at 20°C until the reaction is complete, add water, separate layers, wash with water, concentrate, filter, and dry to obtain 11.1 g of testosterone propionate, with a yield of 111% and a purity of 98.9%.

example 2

[0023] The preparation of example 2 testosterone propionate

[0024] Under argon atmosphere, put 10g of testosterone (17β-hydroxyandrost-4-en-3-one) into 100ml of dichloroethane, add 100ml of triethylamine, 10g of 4-dimethylaminopyridine (DMAP) , add 50ml of propionic anhydride, keep warm at 50°C until complete reaction, add water, separate layers, wash with water, concentrate, filter, dry to obtain 11.2g of testosterone propionate, yield 112%, purity: 98.8%.

example 3

[0025] The preparation of example 3 testosterone propionate

[0026] Under a helium atmosphere, put 10g of testosterone (17β-hydroxyandrost-4-en-3-one) into 200ml of dichloromethane, add 50ml of diisopropylethylamine, 0.01g of 4-dimethylaminopyridine (DMAP), add 4.5ml propionic anhydride, keep warm at 80°C until complete reaction, add water, separate layers, wash with water, concentrate, filter, dry to obtain 11.1g of testosterone propionate, yield 111%, purity: 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com