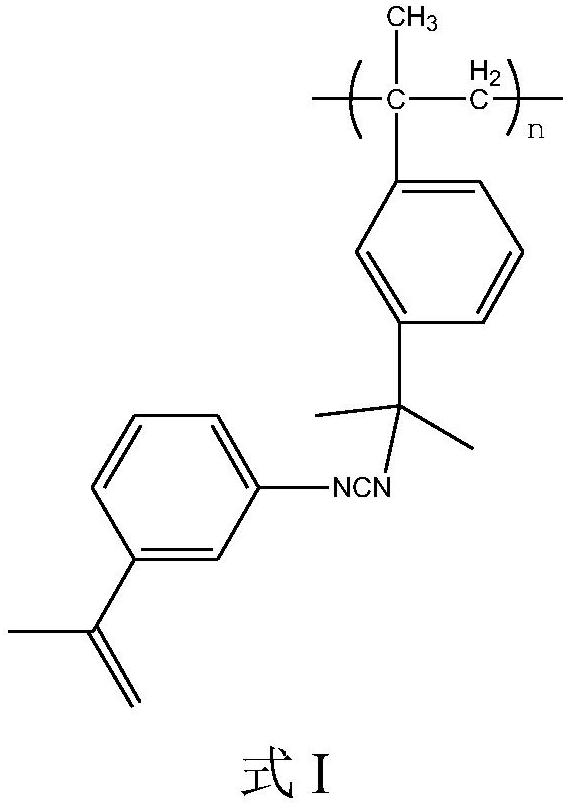

Carbodiimide polymer, preparation method thereof and polymer material containing the carbodiimide polymer

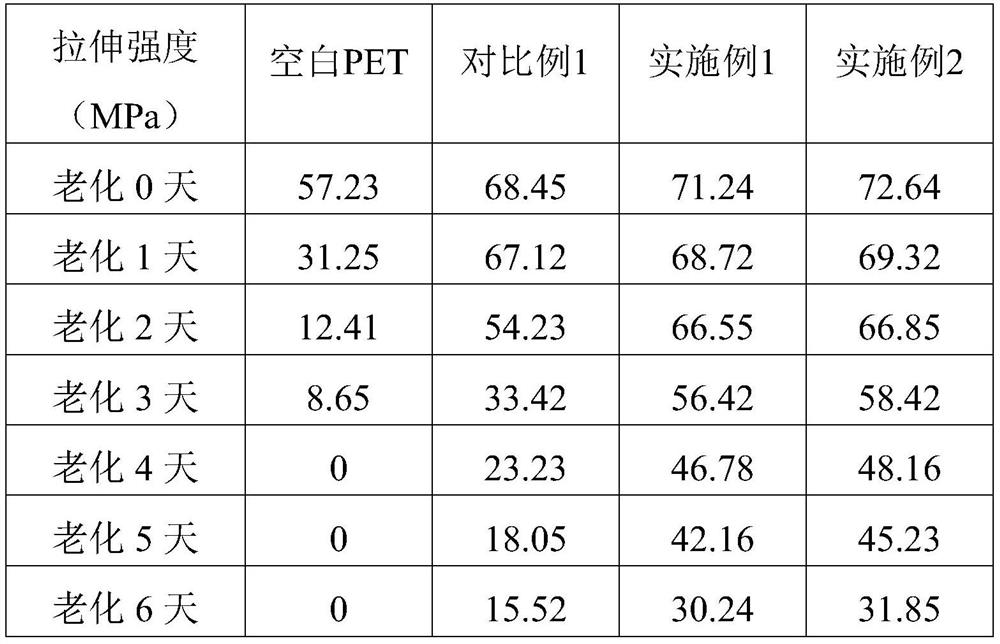

A technology of carbodiimide and polymer materials, which is applied in the field of carbodiimide polymers and their preparation and polymer materials containing them, and can solve the problem of poor aging resistance of polymer materials and compatibility with polymers Poor performance, poor mechanical properties and other problems, to achieve excellent thermal stability, not easy to decompose, simple blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Add 100g of bis[3-isopropenyl-dimethylbenzyl]carbodiimide and 500ml of toluene into a 1000ml glass reaction bottle, and add ferric acetylacetonate and triisocyanate at a molar ratio of 1:15 in sequence under nitrogen protection. A total of 35mg (350ppm) of butylaluminum initiator was reacted in a constant temperature water bath at 40°C for 3h. After the reaction, a small amount of ethanol was added to the reaction system for washing to obtain a white powdery solid polymer with a softening point of 152°C.

Embodiment 2

[0053] Add 2000g of bis[3-isopropenyl-dimethylbenzyl]carbodiimide and 5000ml of dichloroethane into a 10L glass reactor, and add MoCl with a molar ratio of 1:20 in sequence under nitrogen protection. 5 and Al(i-Bu) 3 A total of 800mg (400ppm) of the initiator was reacted in a constant temperature water bath at 50°C for 4h. After the reaction, a small amount of methanol was added to the reaction system for washing to obtain a white powdery solid polymer with a softening point of 155°C.

Embodiment 3

[0055] Add 200g of bis[3-isopropenyl-dimethylbenzyl]carbodiimide and 1000ml of toluene into a 1000ml glass reaction bottle, and then add iron acetylacetonate and triisocyanurate with a molar ratio of 1:15 in sequence under nitrogen protection. A total of 10mg (50ppm) of butylaluminum initiator was reacted in a constant temperature water bath at 40°C for 1h. After the reaction, a small amount of ethanol was added to the reaction system for washing to obtain a white powdery solid polymer with a softening point of 145°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com