Epoxy resin film

A technology of epoxy resin and resin, which is applied in the field of epoxy resin film, can solve the problems of poor heat resistance, chemical corrosion resistance and wear resistance, difficulty in controlling the thickness of the scraping film, and poor effect of manual scraping, so as to facilitate flattening Type, not easy to settle, avoid poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

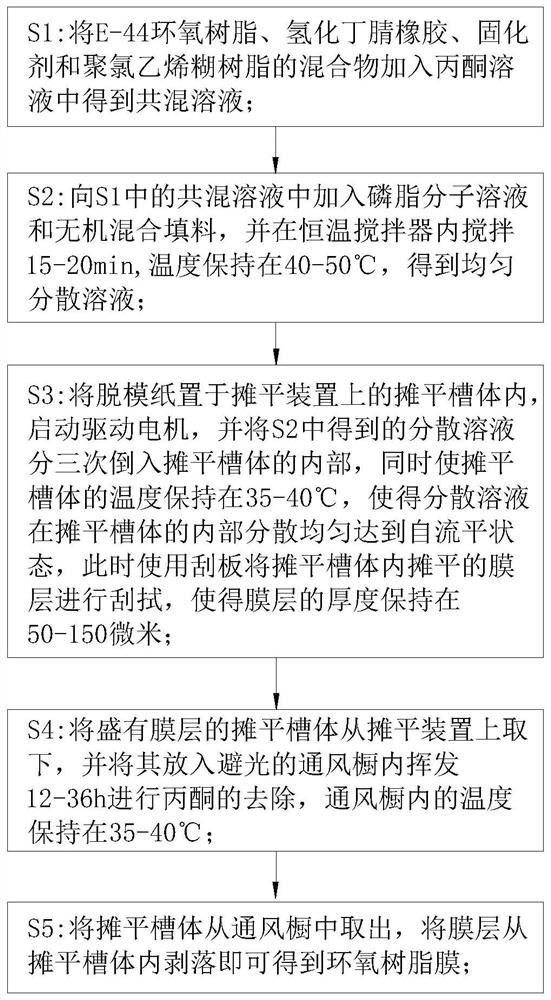

[0035] The preparation method of described epoxy resin film comprises the steps:

[0036] S1: Add the mixture of E-44 epoxy resin, hydrogenated nitrile rubber, curing agent and polyvinyl chloride paste resin to the acetone solution to obtain a blended solution; E-44 epoxy resin has good fluidity and is easy to mix with auxiliary materials. Easy molding and processing, good dimensional stability after curing, shrinkage rate less than 2%, is the resin with the smallest shrinkage rate of thermosetting resins, thermal expansion coefficient 6-10.5%, excellent bonding performance, electrical insulation performance, mechanical properties and chemical stability are all good ; and hydrogenated nitrile rubber has good heat resistance, excellent chemical corrosion resistance and compression set resistance due to its highly saturated structure, as well as high strength, high tear performance and high wear resistance. Advantages, which can improve the performance of epoxy resin film; polyv...

Embodiment approach

[0043] As an embodiment of the present invention, the inorganic mixed filler is mixed with nano-montmorillonite and talcum powder, and the ratio of nano-montmorillonite and talcum powder is 2:1; during work, nano-montmorillonite can make The strength, elongation and other properties of the epoxy resin film are greatly improved by 20%, and some properties can be improved several times. Talc powder can improve the wear resistance and anti-skid performance.

[0044] As an embodiment of the present invention, the type of the curing agent is a phenol amino alcohol curing agent; the phenol amino alcohol curing agent is obtained by modifying an amine curing agent, which is non-toxic and safe.

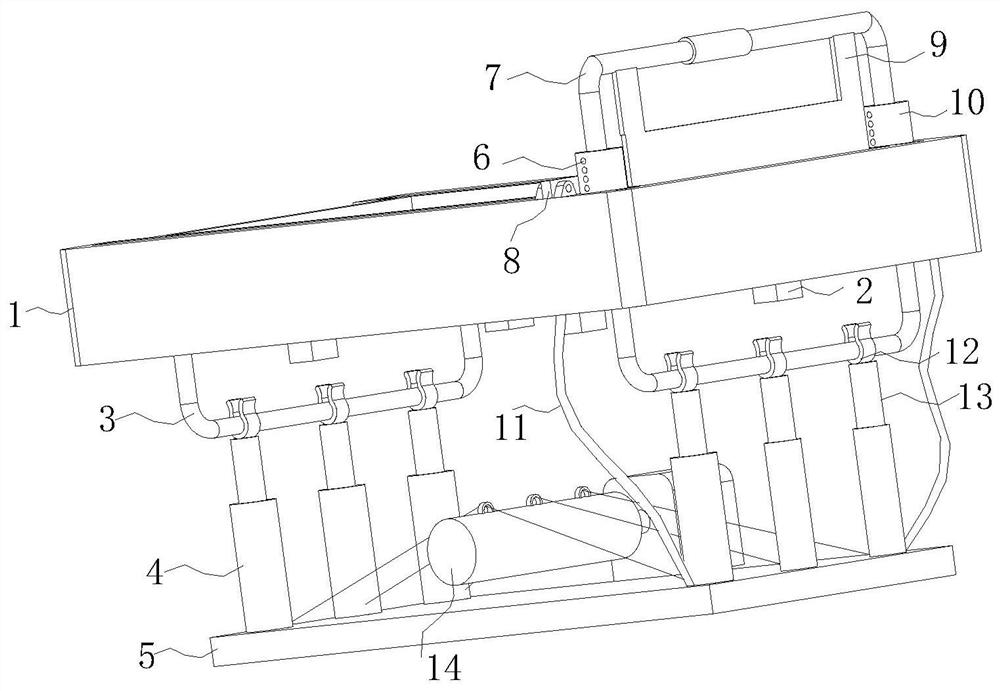

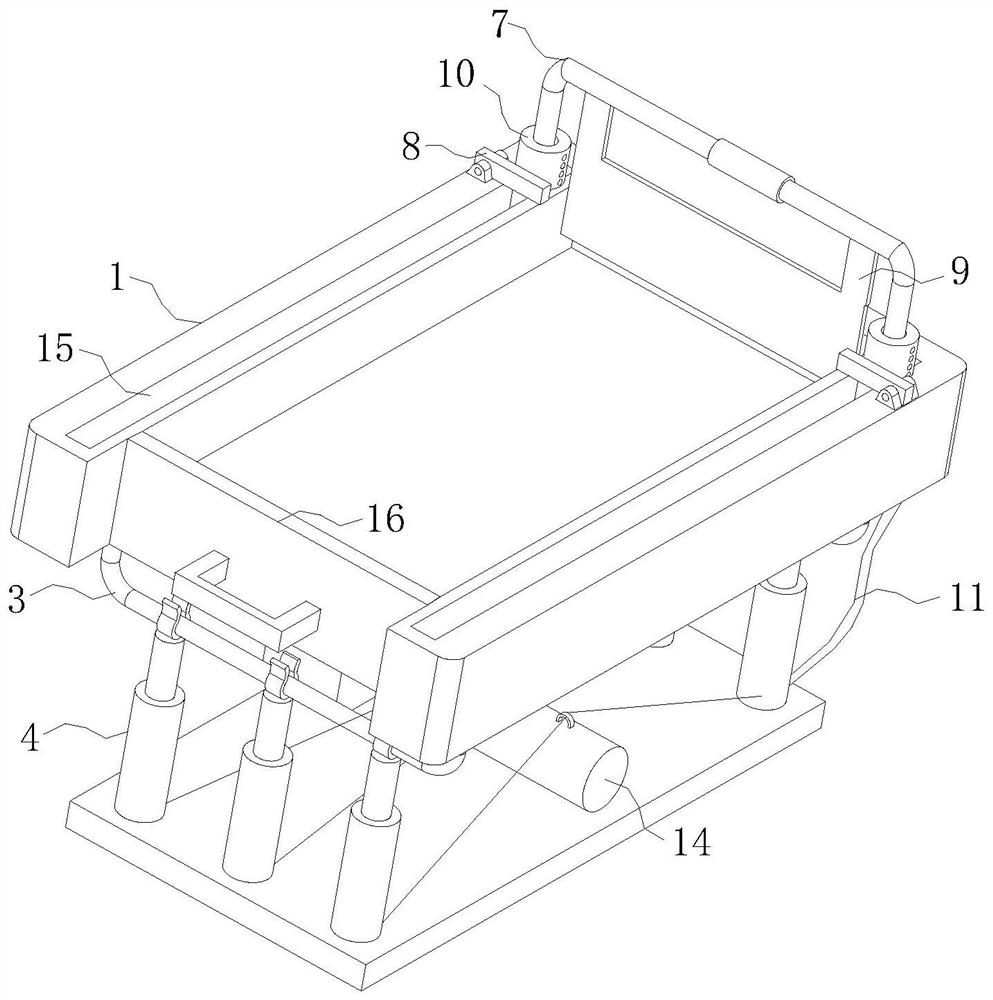

[0045] As an embodiment of the present invention, the bottom of the fixed tube 4 is fixedly provided with a spring compression tube 20; the top of the spring compression tube 20 is provided with a light pressing plate; The pull cord passes through the inside of the spring compression tube 20; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com