High-performance polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and high-performance technology, applied in polyurea/polyurethane coatings, wax coatings, coatings, etc., can solve the problems of easy flow, long surface dry time and hard drying time, sensitive polyurethane waterproof coatings, etc., and achieve low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

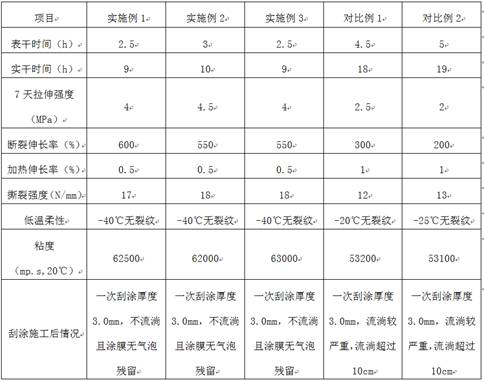

Embodiment 1

[0030] A preparation method of a high-performance polyurethane waterproof coating comprises the following steps: a prepolymer synthesis step, an activation step, a low-temperature catalysis step, and a temperature-raising step.

[0031] In the synthesis step of the prepolymer, 18 parts by weight of polyether polyol is added into a high-shear reaction kettle, and after 10 minutes of high-shear, the reaction temperature is adjusted to 100°C, and then the high-shear reaction is carried out. Add 6 parts by weight of isocyanate and 0.1 part by weight of silicone defoamer by shearing, continue high-shearing and heat-retaining reaction at 70°C for 1 hour to obtain the NCO-based prepolymer, turn off the high-shearing, and NCO The base prepolymer was cooled to 35°C and then stored in a high-shear reactor for later use.

[0032] The polyether polyol, chroma: ≤50, hydroxyl value: 107-117, moisture: ≤0.05, acid value (mgKOH / g): ≤0.05, potassium and sodium ion content (ppm): ≤3, viscosity:...

Embodiment 2

[0039] A preparation method of a high-performance polyurethane waterproof coating comprises the following steps: a prepolymer synthesis step, an activation step, a low-temperature catalysis step, and a heating step.

[0040] In the synthesis step of the prepolymer, 19 parts by weight of polyether polyols are added into a high-shear reactor, and after 11 minutes of high-shear, the reaction temperature is adjusted to 105°C, and then high-shear is carried out. Add 6.5 parts by weight of isocyanate and 0.2 parts by weight of silicone defoamer by shearing, continue high-shearing and heat-retaining reaction at 72°C for 1.5 hours to obtain the NCO-based prepolymer, turn off the high-shearing, and The NCO-based prepolymer was cooled to 36 °C and then stored in a high-shear reactor for further use.

[0041]The polyether polyol, chroma: ≤50, hydroxyl value: 107-117, moisture: ≤0.05, acid value (mgKOH / g): ≤0.05, potassium and sodium ion content (ppm): ≤3, viscosity: (25°C) mPa.s: 130-19...

Embodiment 3

[0048] A preparation method of a high-performance polyurethane waterproof coating comprises the following steps: a prepolymer synthesis step, an activation step, a low-temperature catalysis step, and a temperature-raising step.

[0049] In the synthesis step of the prepolymer, 20 parts by weight of polyether polyol is added into a high-shear reaction kettle, and after 12 minutes of high-shear, the reaction temperature is adjusted to 110°C, and then high-shear is carried out. Add 7 parts by weight of isocyanate and 0.3 parts by weight of silicone defoamer by shearing, continue high-shearing and heat-retaining reaction at 75°C for 2 hours to obtain the NCO-based prepolymer, turn off the high-shearing, and NCO The base prepolymer was cooled to 37°C and then stored in a high-shear reactor for further use.

[0050] The polyether polyol, chroma: ≤50, hydroxyl value: 107-117, moisture: ≤0.05, acid value (mgKOH / g): ≤0.05, potassium and sodium ion content (ppm): ≤3, viscosity: (25°C) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com