High-performance TPV material and continuous automatic production method thereof

A production method and high-performance technology, applied in the field of high-performance TPV materials and their continuous automatic production, can solve problems such as mismatch between comprehensive performance and price, failure to meet actual needs, low added value of products, etc., to achieve good mechanical properties, good Effects of aging performance and excellent low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

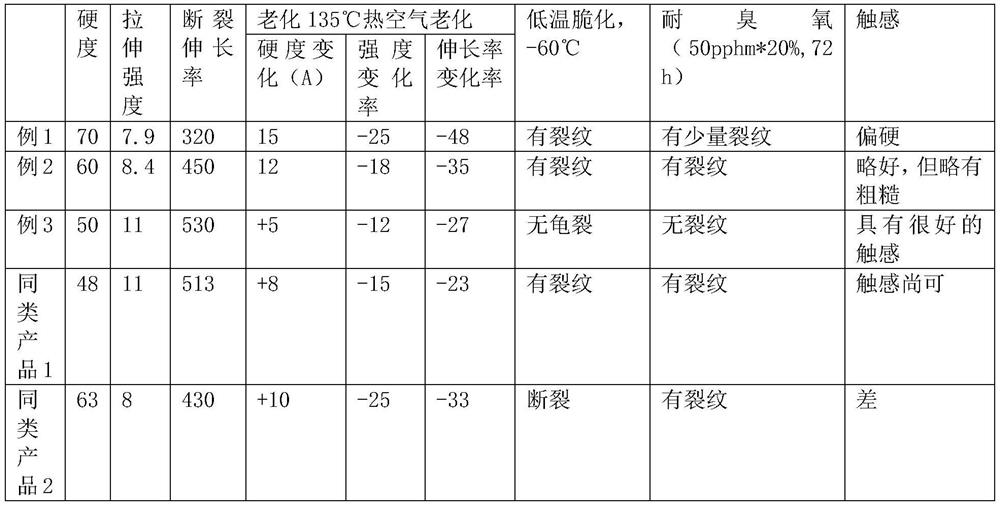

Examples

Embodiment 1

[0036] Embodiment 1: A kind of high-performance TPV material and its continuous automatic production method, EPDM rubber is pulverized to 6mm with 3% filler as the coarse particles of the spacer in the knife-type grinding disc mill, and transported by the cyclone separator To the auxiliary machine silo on the extruder, the continuous feed metering is carried out according to the proportion, specifically, EPDM: 37 parts, random polypropylene: 19 parts, homopolypropylene: 19 parts, anti-aging agent: 4.5 parts, Anti-ultraviolet agent: 0.375 parts, color masterbatch: 1.1 parts, slip agent: 0.3 parts, filler: 9 parts, the materials are continuously added to the feeding hopper by means of weight loss scale and screw metering; the plasticizer is fed from a small side Feed port injection: 35 parts; vulcanizing agent and auxiliary vulcanizing agent are added from the small direction-finding feeding port in the front part, vulcanizing agent: 0.6 parts, auxiliary vulcanizing agent: 0.7 pa...

Embodiment 3

[0038] Embodiment 3: A kind of high-performance TPV material and its continuous automatic production method, EPDM rubber is pulverized in a knife-type disc grinder to 6mm coarse particles with 3% filler as a spacer, and transported by a cyclone separator To the hopper of the auxiliary machine on the extruder, the continuous feed metering is carried out according to the proportion. Among them, EPDM: 50 parts, random polypropylene: 15 parts, homopolypropylene: 15 parts, anti-aging agent: 6.1 parts, anti-ultraviolet agent: 0.5 parts, color masterbatch: 1.5 parts, slip agent: 0.5 parts Parts, filler: 12 parts, the material is continuously added to the feeding hopper through the method of weight loss scale and screw metering; plasticizer is injected from the small side feeding port: 48 parts; vulcanizing agent and vulcanizing agent are from the small front Add to the side feed port, vulcanizing agent: 0.8 part, auxiliary vulcanizing agent: 1 part. The length-to-diameter ratio of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com