Molybdenum-tungsten sputtering target material and preparation method thereof

A sputtering target material, molybdenum and tungsten technology, applied in the field of powder metallurgy, can solve the problems of large density difference, affecting target structure uniformity, delamination or segregation, etc., achieve small density difference, excellent coating effect, and promote the acquisition of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

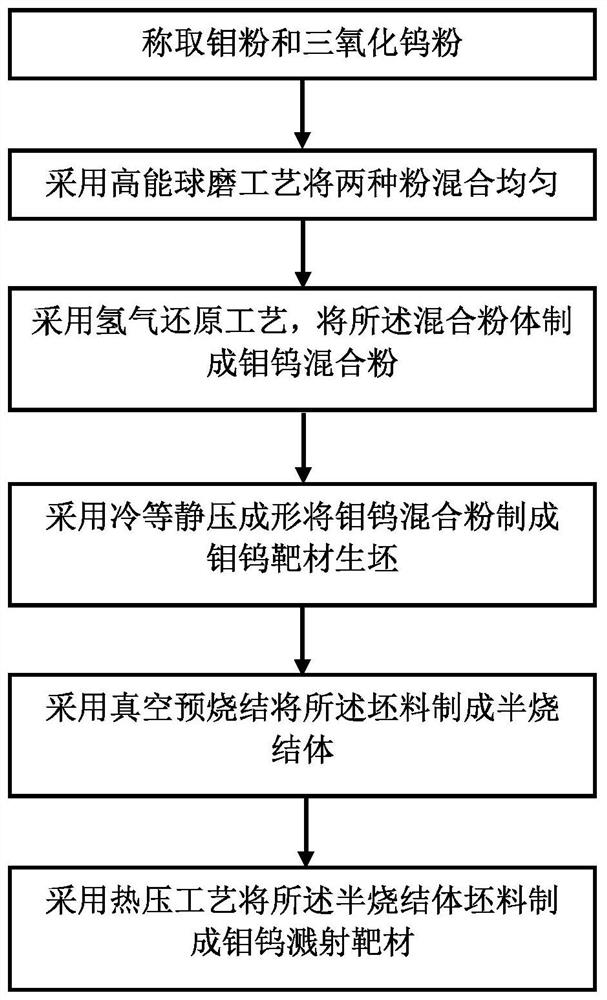

Method used

Image

Examples

Embodiment 1

[0036] 1) Weigh molybdenum powder with a particle size of 6.5μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8μm and a purity of ≥4N according to the mass fraction of 20% of tungsten trioxide;

[0037] 2) The mixture is prepared by high-energy ball milling process under Ar atmosphere, the ball mill rotating speed is 110rpm, the mixing time is 18h, tungsten balls are used as grinding balls, and the ball-to-material ratio is 6:1;

[0038] 3) The mixed powder obtained in step 2) is placed in a molybdenum boat, the thickness of the powder is 10 mm, and the first-stage reduction is carried out at 480 °C for 1 h in a hydrogen furnace, and then the second-stage reduction is carried out at 920 °C for 1.5 h to obtain Molybdenum-tungsten mixed powder;

[0039] 4) forming the molybdenum-tungsten mixed powder obtained in step 3) by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 180MPa, and the pressure holding ...

Embodiment 2

[0044] 1) Weigh molybdenum powder with a particle size of 4.6 μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8.0 μm and a purity of ≥4N according to the mass fraction of 15% of tungsten trioxide;

[0045] 2) The mixture is prepared by high-energy ball milling process in a vacuum atmosphere, the ball mill rotating speed is 120rpm, and the mixing time is 20h; molybdenum balls are used as grinding balls, and the ball-to-material ratio is 10:1;

[0046] 3) The mixed powder obtained in step 2) is placed in a molybdenum boat, the thickness of the powder is 15mm, first-stage reduction is carried out at 460°C for 1.5h in a hydrogen furnace, and then second-stage reduction is carried out at 910°C for 1.2h, Obtain molybdenum-tungsten mixed powder;

[0047] 4) forming the molybdenum-tungsten mixed powder obtained in step 3) by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 150MPa, and the pressure holding tim...

Embodiment 3

[0052] 1) Weigh molybdenum powder with a particle size of 5μm and a purity of ≥3N and tungsten trioxide powder with a particle size of 8μm and a purity of ≥4N according to the mass fraction of 20% of tungsten trioxide;

[0053] 2) The mixture is prepared by high-energy ball milling process under Ar atmosphere, the ball mill rotating speed is 110rpm, the mixing time is 18h, tungsten balls are used as grinding balls, and the ball-to-material ratio is 6:1;

[0054] 3) The mixed powder obtained in step 2) is placed in a molybdenum boat, the thickness of the powder is 10 mm, and the first-stage reduction is carried out at 480 °C for 1 h in a hydrogen furnace, and then the second-stage reduction is carried out at 920 °C for 1.5 h to obtain Molybdenum-tungsten mixed powder;

[0055] 4) forming the molybdenum-tungsten mixed powder obtained in step 3) by cold isostatic pressing (CIP) to obtain a molybdenum-tungsten green body, the forming pressure is 180MPa, and the pressure holding time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com