Pulsed no-pressure container steam engine

A pressure vessel and steam engine technology, which is applied in the field of steam generation of various thermal processes, can solve the problems of high boiler operation cost, high thermal efficiency and low energy consumption, and achieve the effects of simple structure, high thermal efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

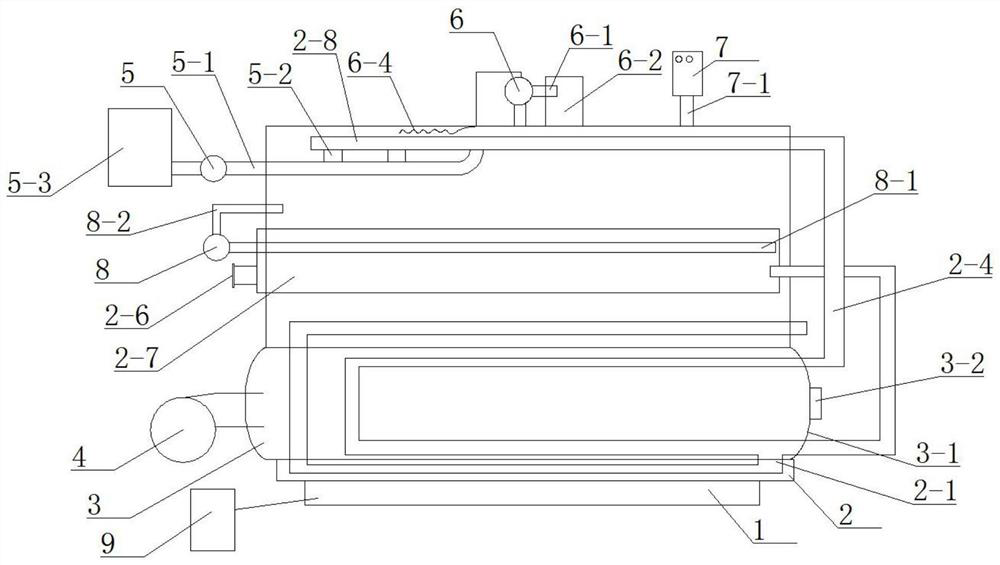

[0018] As a preferred embodiment of the present invention, the PLC microcomputer controller 9 is connected with the water pump 5, the oil circulation pump 8, the gear pump 6-1, the compression grinding conveyor 6, the double-layer evaporator 2-7 and the combustion engine respectively. Electromechanical connection.

[0019] As a preferred embodiment of the present invention, the surface of the combustion bin 3 is provided with refractory mud 3-1.

[0020] As a preferred embodiment of the present invention, the other side of the combustion chamber 3 is provided with a manhole 3-2.

[0021] As a preferred embodiment of the present invention, the combustion chamber 3 is provided with a flue gas inlet pipe 2 - 1 , and the flue gas inlet pipe 2 - 1 is connected and communicated with the oil cylinder 2 .

[0022] As a preferred embodiment of the present invention, the base 1 is provided with an oil cylinder 2 filled with polymer non-metallic energy oil 6-4, and the water pump 5 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com