Porous carbon-graphene composite material and preparation method thereof

A composite material and graphene technology, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of easy collapse of structural junctions and unfavorable use, and achieve improved cycle performance, increased conductivity and specific surface area, and preparation Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention provides a kind of preparation method of porous carbon-graphene composite material, comprises the following steps:

[0027] S1, adding the superabsorbent resin into the graphene oxide solution treated with ultrasound, and freeze forming;

[0028] S2. Freeze-drying in a vacuum environment to obtain a superabsorbent resin-graphene oxide composite material;

[0029] S3. Under a protective atmosphere, the obtained composite material is sequentially carbonized at 500-1000° C., washed, dried to constant weight, and the porous carbon-graphene composite material is ground.

[0030] The embodiment of the present invention uses superabsorbent resin, water and a small amount of graphene oxide as raw materials, and the cost is relatively low. The graphene oxide solution will fill the superabsorbent resin, and the structure of the porous carbon-graphene composite material obtained after carbonization will not collapse. Moreover, graphene oxid...

Embodiment 1

[0041] Prepare a graphene oxide solution with a concentration of 0.5g / L and ultrasonicate for 30 minutes, take 1g of sodium polyacrylate and add it to 100ml of the intrinsic graphene oxide solution and stir. Dry to constant weight, and heat at 800° C. for 120 min under a nitrogen atmosphere. After carbonization is completed, wash, dry to constant weight, and grind to obtain a porous carbon-graphene composite material.

[0042] Making Porous Carbon-Graphene Composites into Button Cells. After the electrochemical performance test, when the current density is 0.1C, the first discharge specific capacity is 353.81mAh / g, after 100 cycles, the discharge specific capacity is 383.90mAh / g, the capacity retention rate is 108.50%, and the cycle performance is excellent.

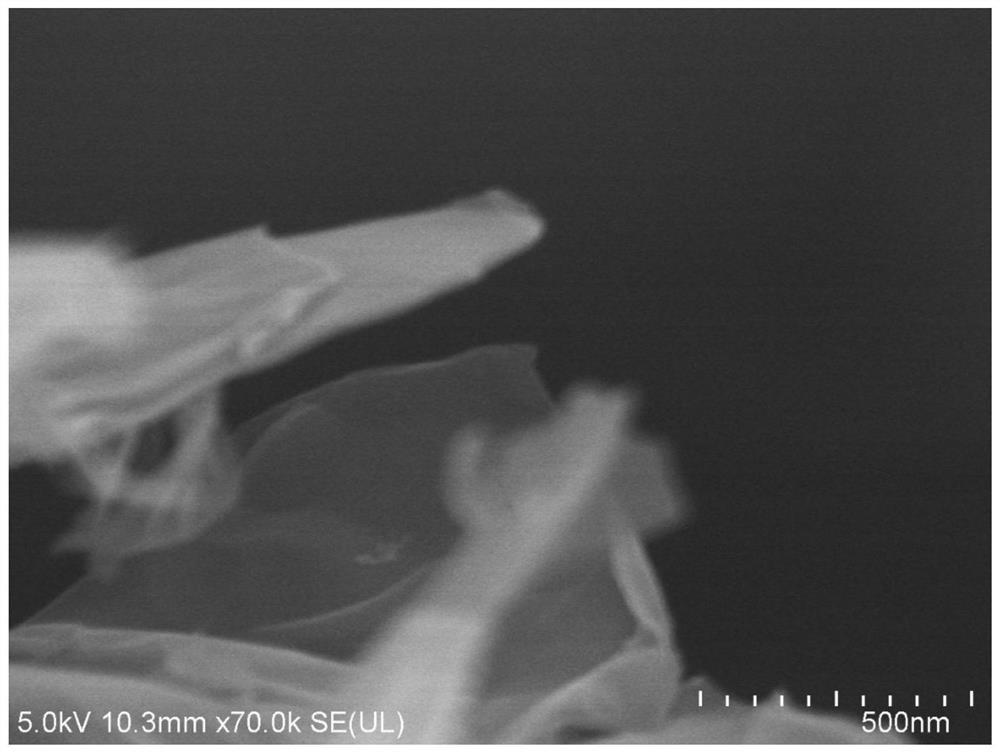

[0043] figure 1 Obtain the SEM figure of graphene after graphene oxide reduction in the present embodiment, from figure 1 It can be seen that graphene oxide has good dispersion and is a single layer, which can give ful...

Embodiment 2

[0045] A nitrogen-doped graphene oxide solution with a concentration of 0.5g / L was ultrasonicated for 30min, and 1g of sodium polyacrylate was added to 100ml of graphene oxide solution and stirred to make it evenly distributed, and freeze-dried to constant weight. Heating at 500°C for 30 minutes, after carbonization, washing to remove salt ions therein, drying to constant weight, and grinding to obtain a porous carbon-graphene composite material.

[0046] Porous carbon-graphene composites are used as anode materials for lithium-ion batteries to make button batteries. After the electrochemical performance test, when the current density is 0.1C, the first discharge specific capacity is 334.29mAh / g, after 100 cycles, the discharge specific capacity is 340.28 mAh / g, the capacity retention rate is 101.79%, and the cycle performance is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com