Solid electrolyte material, preparation method thereof and solid-state lithium battery

A technology of solid electrolyte and solid electrolyte layer, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, electrolyte, etc., can solve the problems of low ionic conductivity, insufficient matching of layered oxide cathode materials, insufficient support for lithium ion migration, etc. , to achieve the effect of improving ionic conductivity, broad application prospects, and improving electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

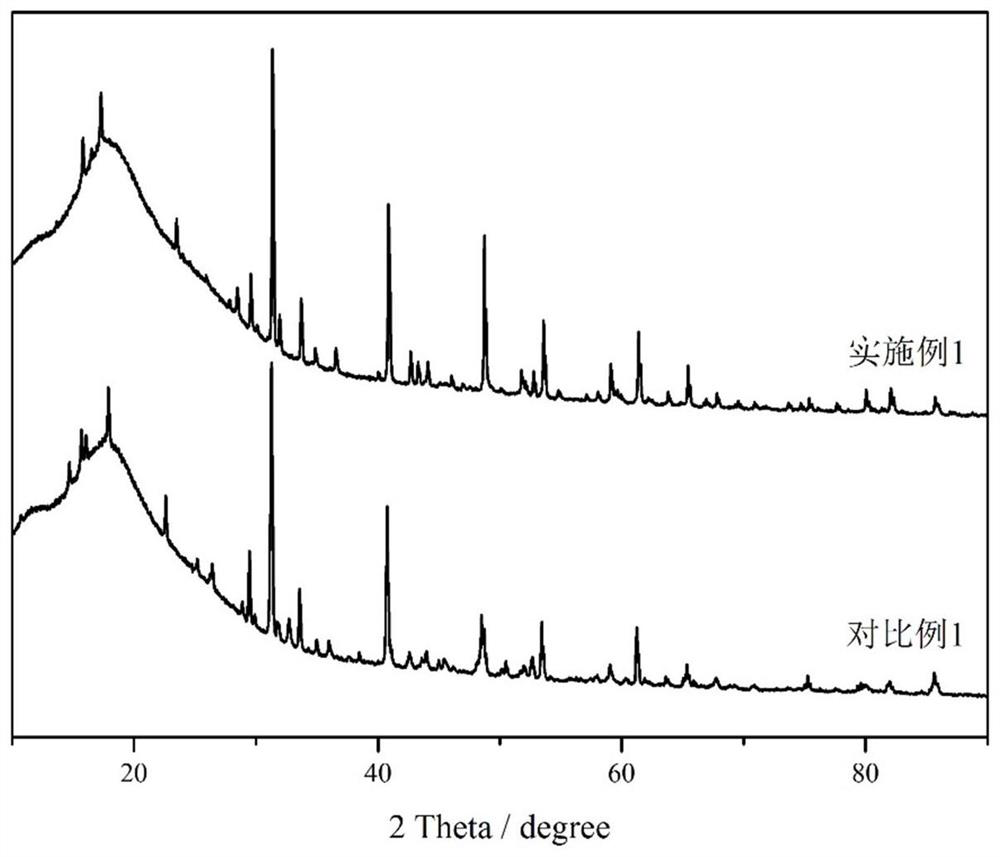

[0041] Example 1: Li 3 YCl 5.7 f 0.3 solid electrolyte material

[0042] Weigh anhydrous YCl at a molar ratio of 0.9:3:0.1 3 , LiCl and YF 3 , mixed evenly and placed in a sealed quartz tube, heated to 520°C for 12 hours under vacuum for solid phase sintering, ground and crushed after cooling. The resulting product is F - Anion-doped Li 3 YCl 5.7 f 0.3 solid electrolyte material.

Embodiment 2

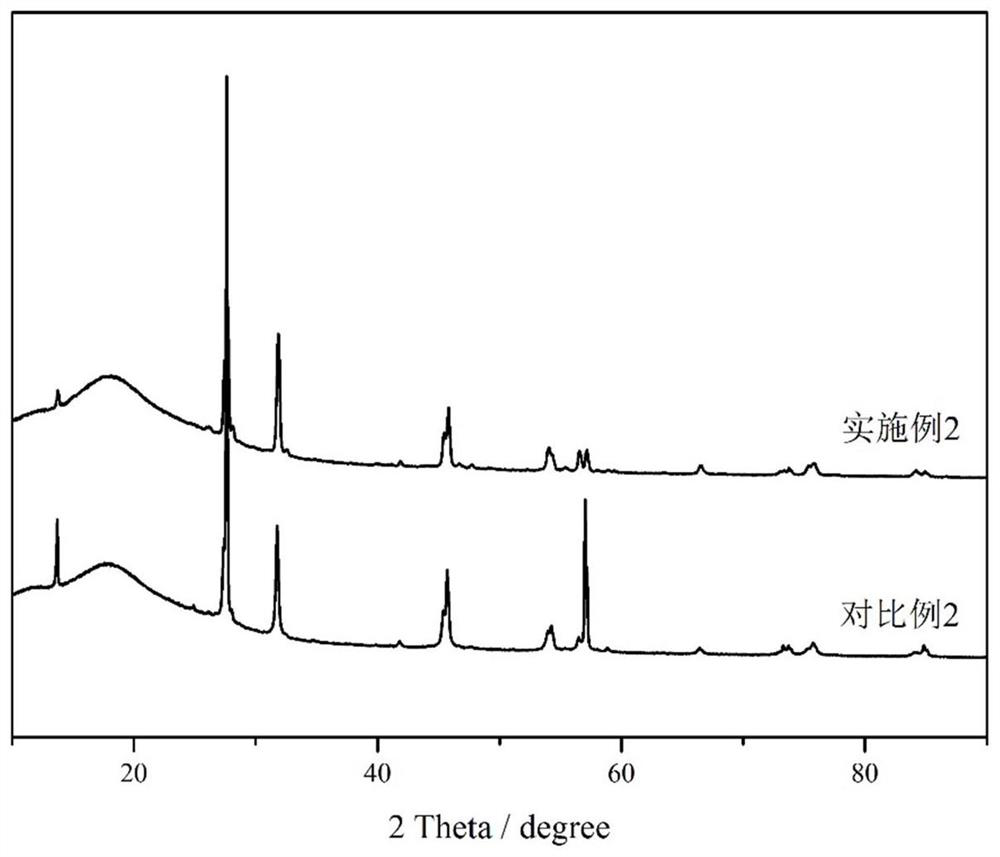

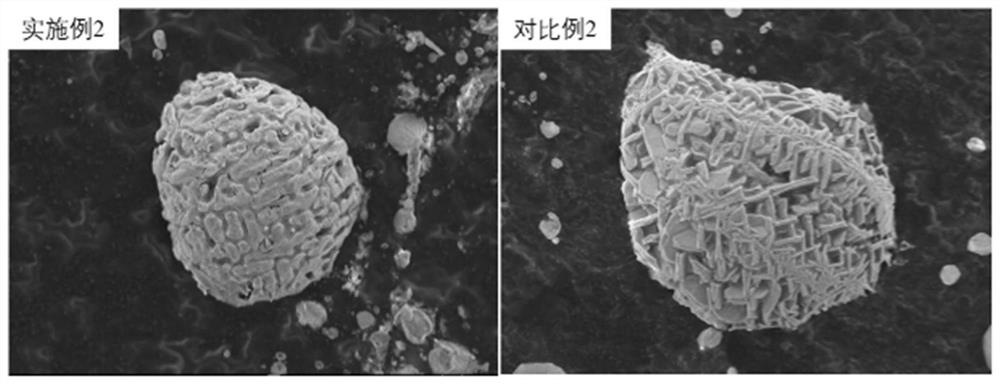

[0043] Example 2: Li 3 YBr 5.7 f 0.3 solid electrolyte material

[0044] Weigh the anhydrous YBr respectively according to the molar ratio of 0.9:3:0.1 3 , LiBr and YF 3 , mixed evenly and placed in a sealed quartz tube, heated to 530°C for 10h under vacuum for solid-phase sintering, ground and crushed after cooling. The resulting product is F - Anion-doped Li 3 YBr 5.7 f 0.3 solid electrolyte material.

Embodiment 3

[0045] Example 3: Li 2.5 YBr 5.0 f 0.5 solid electrolyte material

[0046] Weigh anhydrous YBr respectively according to molar ratio 2.5:7.5:0.5 3 , LiBr and YF 3 , mixed evenly and placed in a sealed quartz tube, heated to 530°C for 10h under vacuum for solid-phase sintering, ground and crushed after cooling. The resulting product is F - Anion-doped Li 2.5 YBr 5.0 f 0.5 solid electrolyte material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com