Preparation method of hippophae rhamnoides branch and trunk feed

The technology of sea buckthorn and branches is applied in the field of preparation of sea buckthorn branch and dry feed, and achieves the effects of improving the yield of enzymatic hydrolysis and saccharification and improving the feeding value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

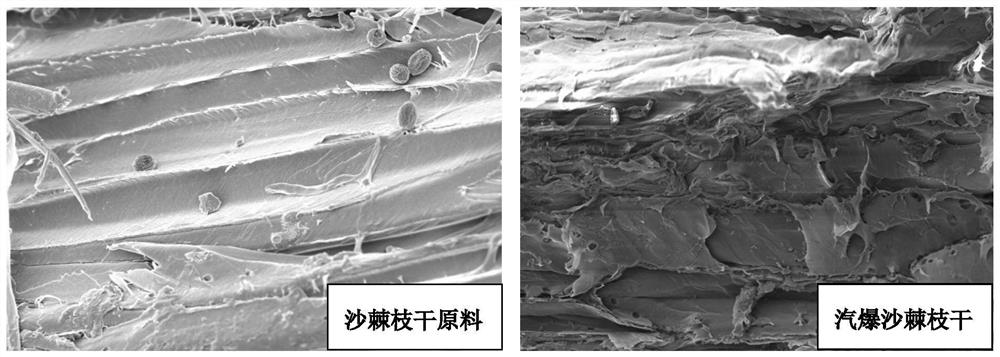

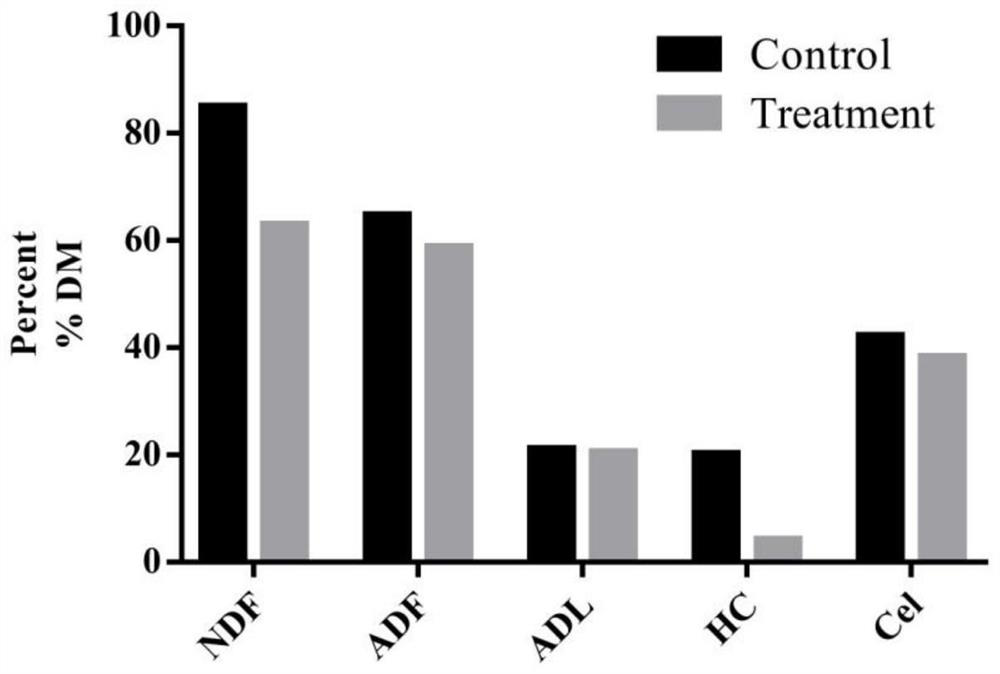

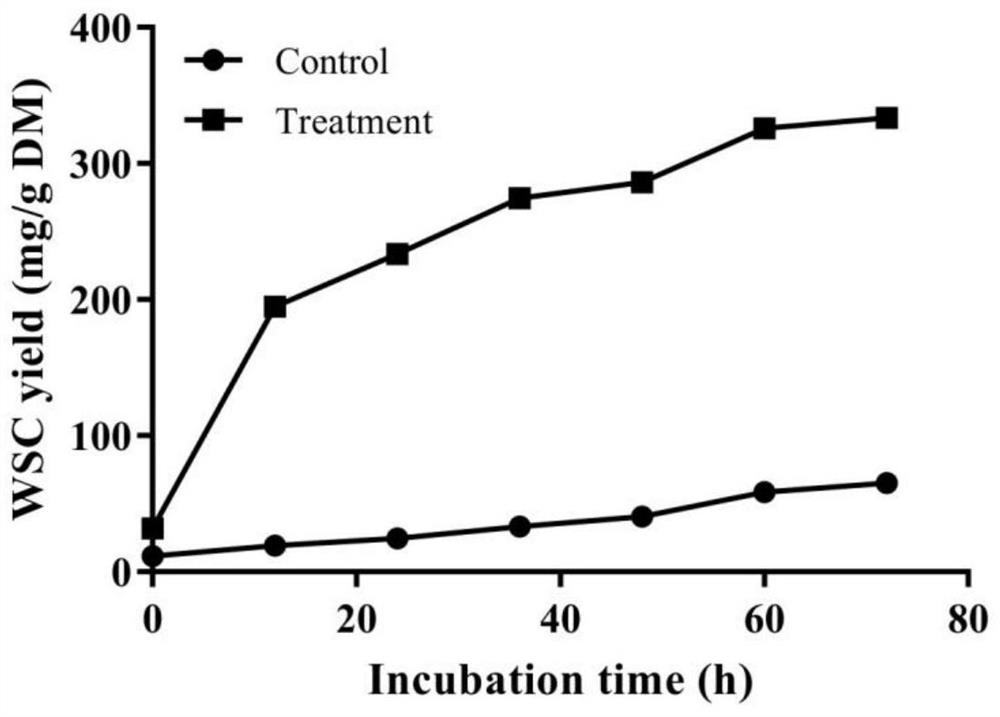

[0026] Example 1: Effects of different combinations of processing parameters on the physical and chemical properties of steam-exploded seabuckthorn branches

[0027] (1) Preparation of pulverized seabuckthorn branches:

[0028] The whole plant of Hippophae rhamnoides is air-dried naturally (about 90% dry matter content), branches and leaves are separated and removed, and then the branches and trunks of Hippophae rhamnoides are crushed through a 2cm sieve with a T-420 wood grinder (Guangzhou Minfeng Agricultural Machinery Co., Ltd.). The pulverized branches of seabuckthorn (dry matter content 90.05%) were obtained.

[0029] (2) Steam explosion processing of seabuckthorn branches:

[0030] Use a special steam explosion device (BL-08 laboratory mobile blaster independently designed by the State Key Laboratory of Pulp and Paper Engineering, South China University of Technology, two tanks in parallel, each volume 5L, maximum pressure 4.0MPa) to step (1 ) obtained pulverized seabu...

Embodiment 2

[0039] Example 2: Effects of different calcium oxide addition levels on storage characteristics of steam-exploded seabuckthorn branches

[0040] (1) Steam explosion processing of seabuckthorn branches:

[0041] The seabuckthorn branch (dry matter content 90.05%) that will be pulverized according to the preparation in embodiment 1 step (1) is dropped in the steam explosion device, with optimum steam explosion processing parameter (pressure 1.5MPa, holding time 20min, without pre-treatment Soaked without additives) for steam explosion processing to obtain steam-exploded seabuckthorn branches.

[0042] (2) Alkalization of steam-exploded seabuckthorn branches:

[0043] Add water to adjust the moisture content of steam-exploded seabuckthorn branches to 65% (close to saturation), then add calcium oxide according to different mass ratios (0, 2%, 4%) of the total mass of the wet material, stir evenly, and finally pack it into a bag, compact and seal it , stored at room temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com