Perovskite type cesium lead bromide quantum dot composite Bi2WO6 photocatalyst and preparation method thereof

A lead cesium bromide quantum and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of scarcity of photocatalysts, achieve high catalytic efficiency, improve degradation efficiency, The effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A perovskite-type lead cesium bromide quantum dot composite Bi 2 WO 6 The preparation method of photocatalyst comprises the following steps:

[0034] 1) Preparation of cesium oleate: drop 1.5 mol of cesium carbonate into a three-necked flask containing 2.6 mol of oleylamine and 3 mol of 1-octadecene and heat in an oil bath for 1 hour, then feed nitrogen and heat up. Then hexanoic acid and oleic acid were added sequentially, and the reaction was vigorously stirred for 0.5 hours;

[0035]2) Preparation of lead bromide quantum dots: mix 40ml of ethanol and 50ml of toluene evenly, add 2mol of octylamine, stir evenly, heat to 85°C in a water bath, grind 1mol of lead bromide into powder and add it to acetic acid , then add 2.5mol of N, N dimethylamide and the product obtained in step 1), raise the temperature of the water bath to 80° C., and react for 12 hours under slow stirring to obtain lead cesium bromide quantum dots;

[0036] 3) Bi 2 WO 6 Preparation: Take 1mol of ...

Embodiment 2

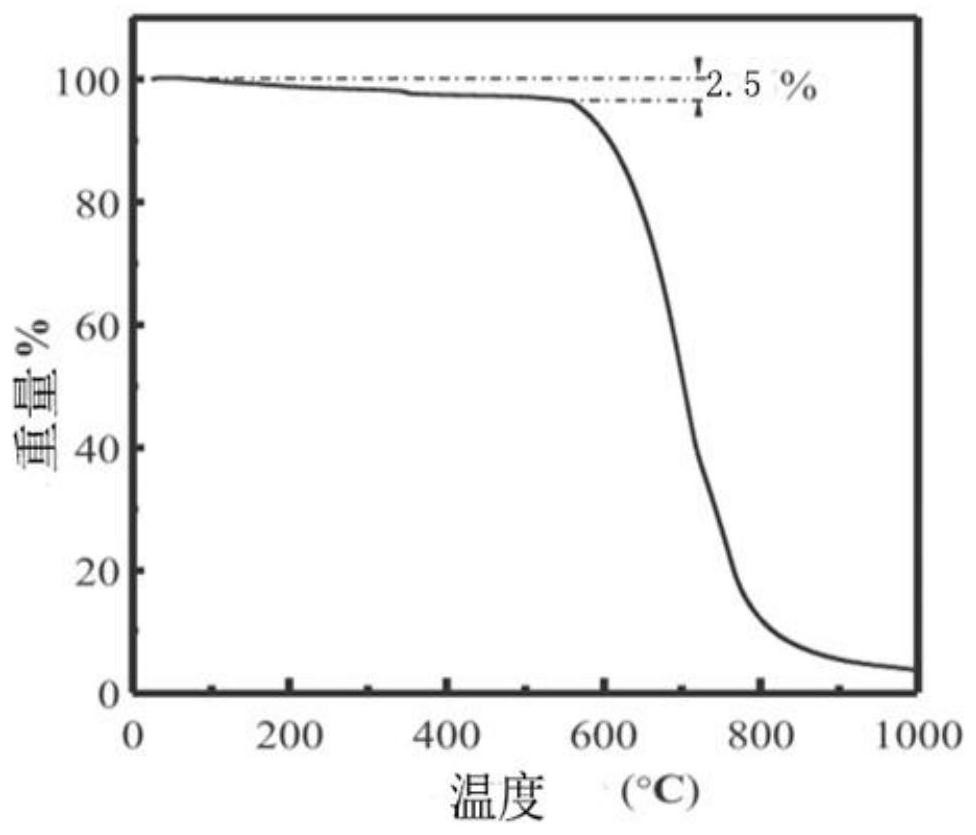

[0040] For a perovskite-type lead cesium bromide quantum dot composite Bi 2 WO 6 The temperature of the photocatalyst was regulated before nitrogen gas was introduced, and the other steps of the steps were completely consistent with those in Example 1. In step 1) in the oil bath temperature, when the oil bath temperature is less than 150°C, the weight drops sharply at 300°C in the thermogravimetric test, and the low oil bath temperature is not conducive to the perovskite type lead cesium bromide quantum dot composite Bi 2 WO 6 Preparation of photocatalyst perovskite structure, making perovskite-type lead cesium bromide quantum dots composited with Bi 2 WO 6 The thermal stability of the photocatalyst is greatly reduced.

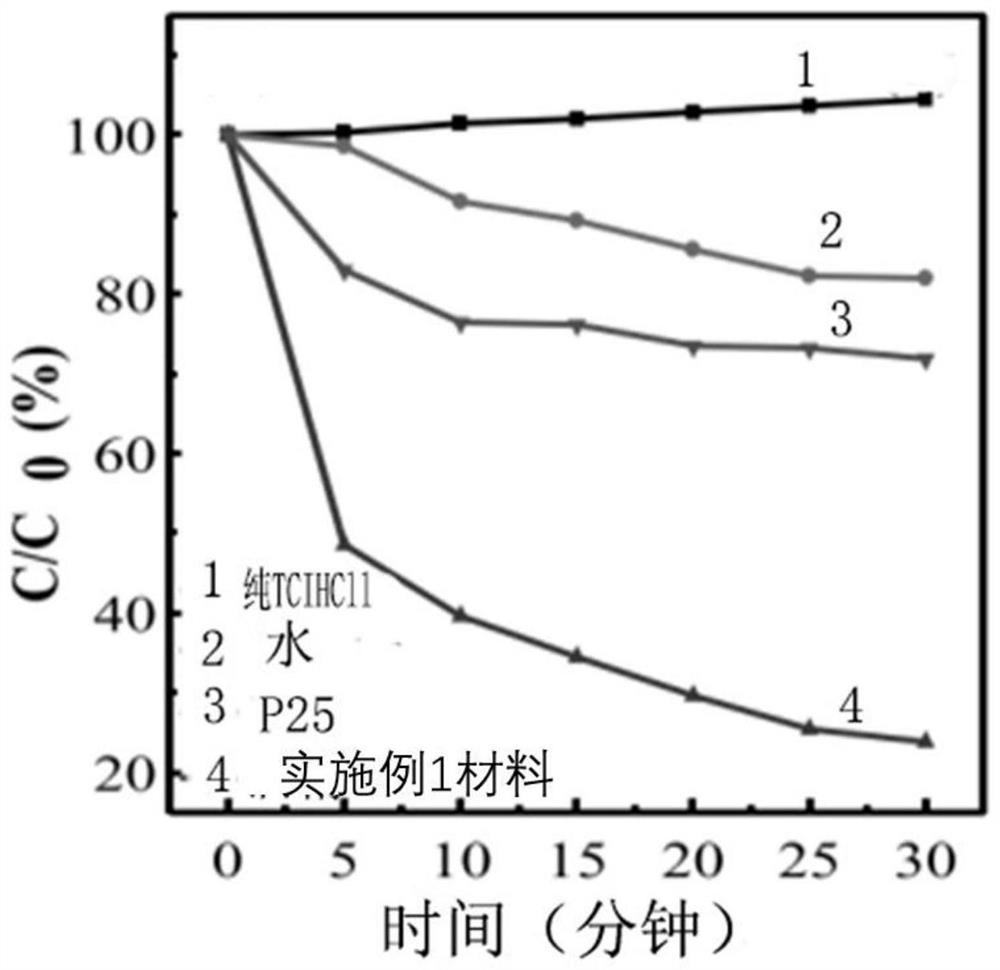

[0041] Applied experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com