Dimethyl sulfoxide industrial waste liquid regeneration treatment process for producing DIANP explosives

A dimethyl sulfoxide, industrial waste liquid technology, applied in filtration treatment, natural water treatment, water/sewage treatment and other directions, can solve problems such as decomposition and safety hazards, achieve control of discharge, reduce environmental pollution, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

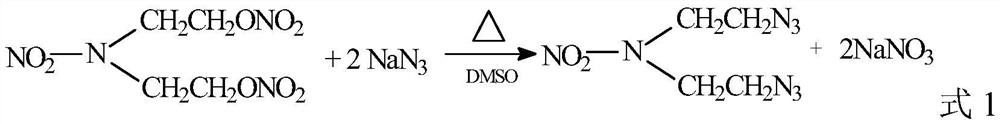

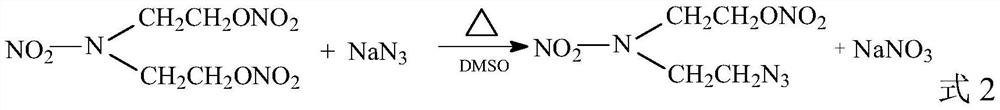

Method used

Image

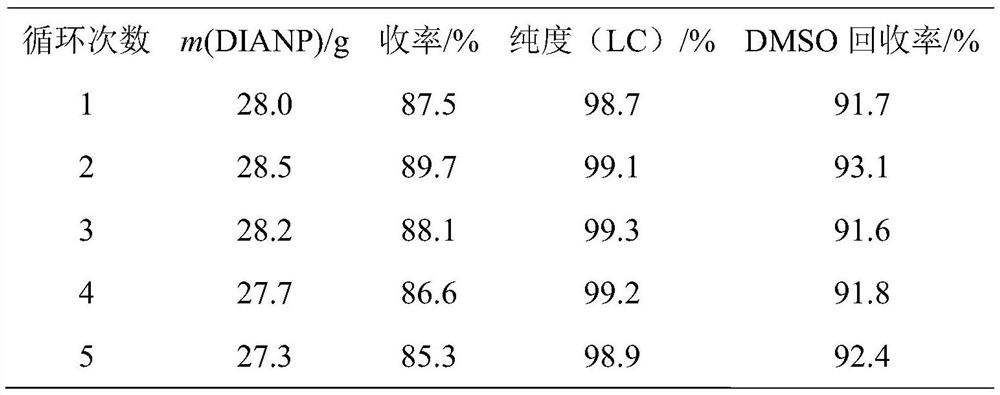

Examples

Embodiment 1

[0036] This embodiment provides a kind of dimethyl sulfoxide industrial waste liquid regeneration treatment process for producing DIANP explosives, which specifically includes the following steps:

[0037] Step 1, vacuum distillation: add 300mL of dimethyl sulfoxide industrial waste liquid containing DIANP explosives into a 500mL vacuum distillation bottle, and gradually raise the temperature under the condition that the vacuum degree is not lower than 0.084MPa, and the temperature of the solution reaches a maximum of 90°C , when the temperature of the distillation head is 50-55 ℃, there is water distilled out, and when the water output is not less than 70% of the total water, the heating can be stopped and the distillation can be stopped;

[0038] Step 2, desalination: cooling and crystallizing the waste liquid obtained after step 1 distillation, the cooling end point reaches a minimum of 30°C, vacuum filtration, and collecting the filtrate;

[0039] Step 3, water removal: Di...

Embodiment 2

[0046] Same as Example 1, the difference is that the mass ratio of sodium azide to N-nitro-diethanolamine dinitrate in step 5 in this example is 0.56:1, in step 6, keep warm for 7 hours, and finally obtain DIANP 26.2 g. The yield is 81.9%, and the purity is 92.0%.

Embodiment 3

[0048] Same as Example 1, the difference is that the mass ratio of sodium azide and N-nitro-diethanolamine dinitrate in step 5 in this example is 0.65:1, in step 6, keep warm for 9h, and finally obtain DIANP 27.8g. Yield 86.9%, purity 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com