A kind of preparation method of coumarone resin for high carbon residue carbon fiber

A technology of coumarone resin and carbon fiber, which is applied in the field of preparation of coumarone resin for carbon fiber with high carbon residue, can solve problems that are not conducive to carbon fiber processing, and achieve low toluene and quinoline insolubles, high carbon residue, and ash content small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

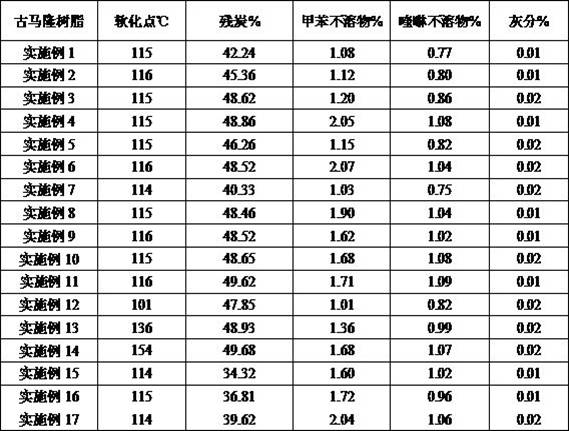

Examples

preparation example Construction

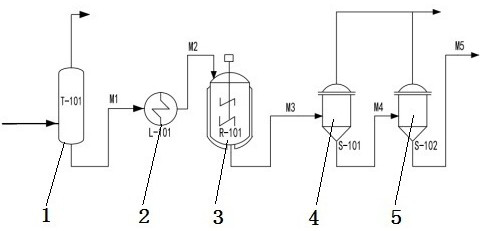

[0019] A preparation method of coumarone resin for high carbon residue carbon fiber is characterized in that, it is carried out according to the following steps:

[0020] (1) Light components are removed from ethylene tar to obtain heavy tar, and the mass percentage of carbon residue in the heavy tar is 15-20%;

[0021] (2) Heavy tar is pyrolyzed in a pyrolysis furnace with a pyrolysis temperature of 400-430°C and a pyrolysis time of 60-180 s to obtain heavy oil after pyrolysis. The mass percentage of carbon residue in the heavy oil is 35% ~40%;

[0022] (3) Heavy oil is polymerized in a polymerization kettle, polymerized at 280-300°C for 5-8 hours, and the mass percentage of carbon residue in the obtained product is 45-50%;

[0023] (4) The polymerized product is subjected to falling film flash evaporation, concentrated and granulated to obtain coumarone resin.

[0024] The light component removal condition of ethylene tar in step (1) is concentration at 200-250°C under neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com