Mechanoluminescence composite material as well as preparation method and application thereof

A composite material and electroluminescence technology, applied in the directions of luminescent materials, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process of high-purity calcium carbonate, limiting the low-cost production and application of electroluminescent composite materials, and high price. Beneficial for mass production applications, low cost, and the effect of improving luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

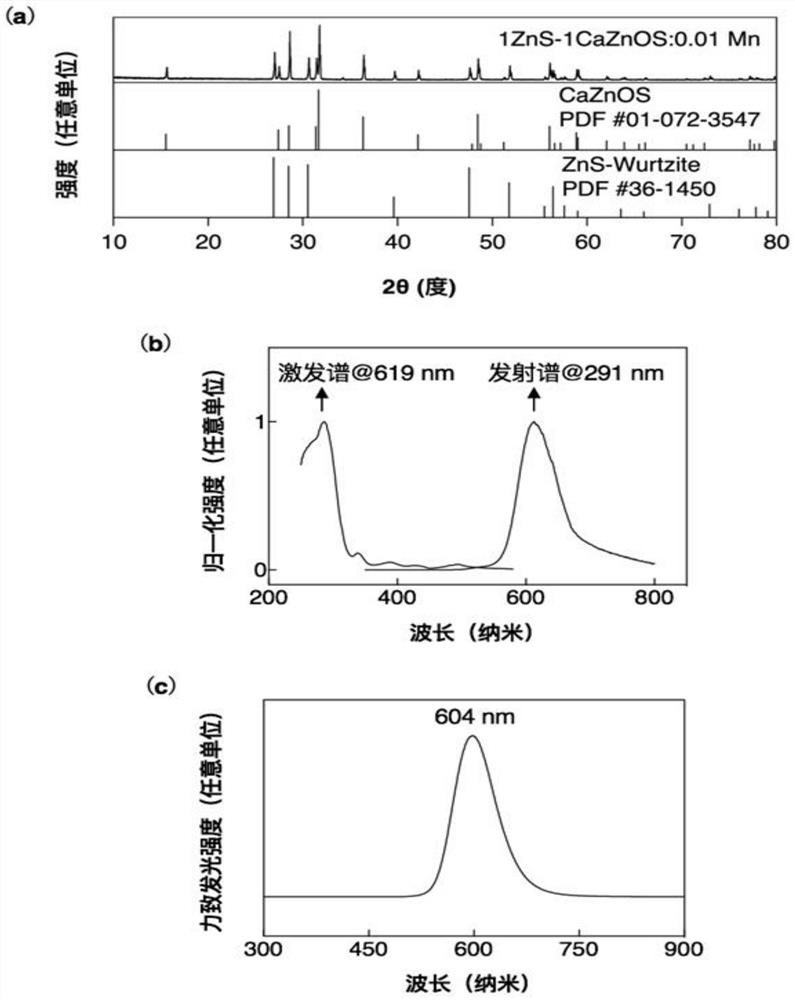

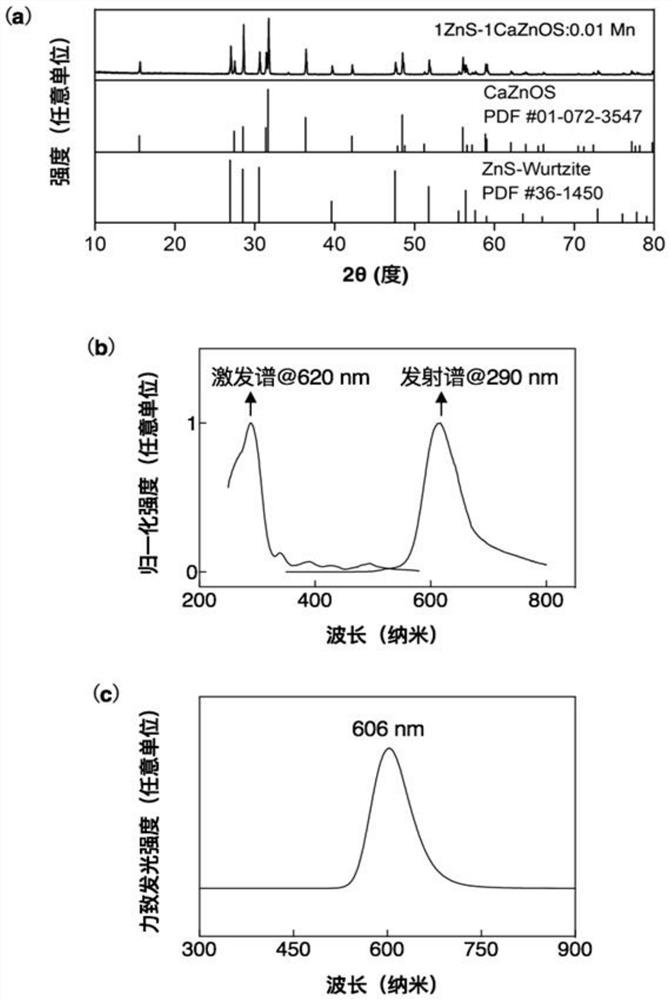

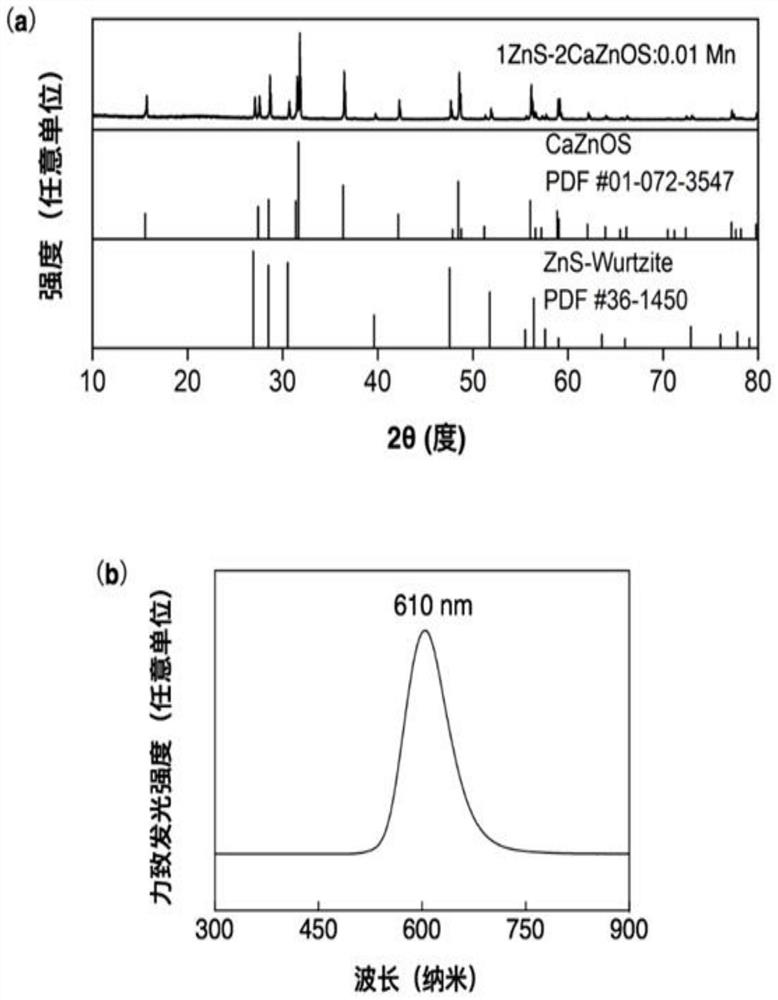

[0042] The present invention also provides a method for preparing a force-luminescence composite material according to an embodiment, which includes the following steps: mixing and sintering eggshells, zinc sulfide and a compound containing doped ions to prepare a force-luminescence composite material. Including mZnS-nCaZnOS: xM, where M is a doped ion, and m, n and x represent the number of moles of ZnS, CaZnOS and M, respectively.

[0043] Specifically, the egg shell is selected from at least one of egg shells, duck egg shells, goose egg shells and bird egg shells. The main component of the eggshell is calcium carbonate, with a mass percentage of up to 95%, and the remaining components are protein (about 3.5% by mass) and a variety of trace elements (zinc, copper, manganese, etc.), which are very suitable as a calcium source It is used for the low-cost production and related applications of zinc sulfide-zinc oxyzinc calcium calcium luminescence composite materials. Experiments...

Embodiment 1~ Embodiment 6

[0070] The preparation process of the photoluminescent composite material of Example 1 to Example 6 is as follows:

[0071] (1) Weigh the raw materials according to the raw material ratio in Table 1 and mix them in an agate mortar, then add an appropriate amount of absolute ethanol, grind until the ethanol is almost volatilized, and then repeat the above grinding process.

[0072] (2) Transfer the ground powder to an alumina ceramic boat, and place it in a blast drying oven at 70°C for 5 hours in the atmosphere, and then transfer it to a high temperature tube furnace at a temperature of 5°C / min The speed was increased to 1100°C, and the temperature was kept for 6 hours in an Ar atmosphere. After the alumina ceramic boat is cooled to room temperature with the furnace, the sample is taken out, crushed, and sieved to obtain the zinc sulfide-zinc oxyzinc calcium calcium luminescence composite material of the embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com