Alkaline multi-surface cleaning agent

A multi-surface, cleaning agent technology, applied in the field of cleaning agents, can solve the problems of easy residue, damaged surface, and no cleaning agent, etc., and achieve the effect of improving surface activity, improving wetting performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

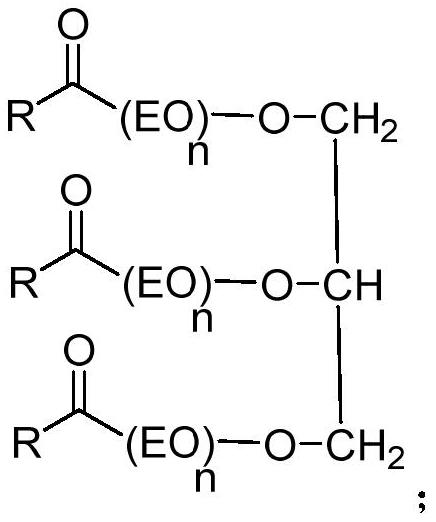

Method used

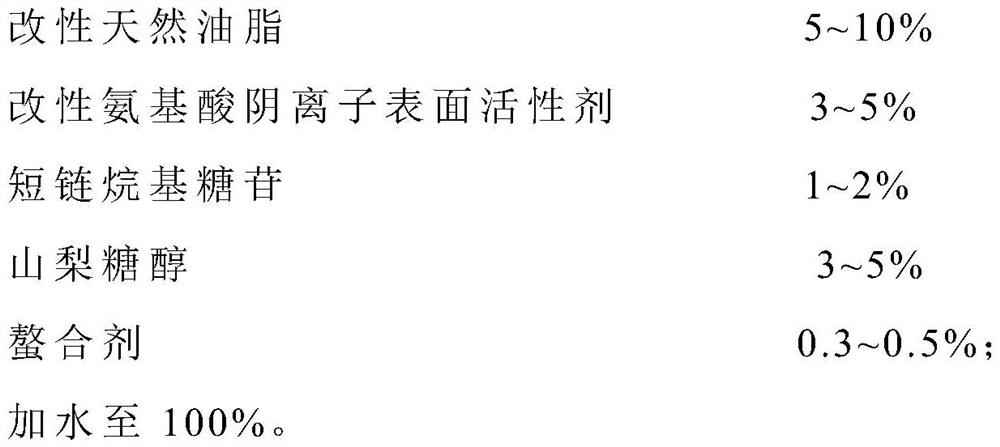

Image

Examples

Embodiment 1

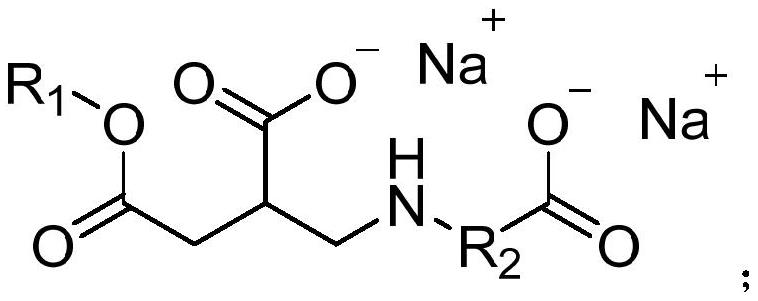

[0038] Synthesis of threonine anionic surfactant modified by palmityl alcohol

[0039]

[0040] Step 1: Add 112g of itaconic anhydride and 242g of palmitic alcohol into a 1-liter flask, slowly raise the temperature to 70 degrees Celsius, and keep the temperature within the range of 70 to 75 degrees Celsius. After the itaconic anhydride is completely dissolved, continue to heat up to 95 degrees Celsius The reaction was carried out for 8 hours under stirring, and palmitic acid monoester could be obtained after cooling.

[0041] Step 2: Add 60 g of threonine and 40 g of sodium hydroxide into 500 ml of water, stir and dissolve completely, heat to 45 degrees Celsius, dissolve 177 g of itaconate palmitate monoester obtained in step 1 in 400 ml of ethanol, stir Slowly add dropwise to the above solution, keep the dropwise addition time for 1-1.5 hours, after the dropwise addition, continue to keep the temperature for 6 hours for reaction. The reaction solution was cooled to 0 degr...

Embodiment 2

[0044] Synthesis of palmityl alcohol modified glycine anionic surfactant

[0045]

[0046] Step 1: Consistent with Step 1 of Example 1.

[0047] Step 2: Add 37.6g of glycine and 40g of sodium hydroxide into 500 milliliters of water, stir and dissolve completely, heat to 45 degrees Celsius, dissolve 177g of palmitic monoester itaconate obtained in step 1 in 400 milliliters of ethanol, stir slowly Slowly add it dropwise to the above solution, keep the dropwise addition time for 1-1.5 hours, after the dropwise addition, continue to keep the temperature for 6 hours reaction. The reaction solution was cooled to 0 degrees Celsius with an ice-water cooling bath, filtered, and the solid was washed 2-3 times with 250 milliliters of ice ethanol, and the solid was put into a vacuum oven for drying at 60 degrees Celsius to obtain 185 g of palmityl alcohol-modified threonyl anionic surfactant.

[0048] The HLB value of palmityl alcohol-modified glycine anionic surfactant was calculated...

Embodiment 3

[0050] Table 1 below shows the component ratios (mass percentages) of the six formulations of the alkaline multi-surface cleaning agent.

[0051] Table 1:

[0052] Recipe 1 Recipe 2 Recipe 3 Recipe 4 Recipe 5 Recipe 6 Modified Natural Oils (SOE) 5 8 10 5 8 10 Modified Threonine Anionic Surfactant 5 3 3 0 0 0 Modified Glycine Anionic Surfactant 0 0 0 5 3 3 C6~C8 short chain alkyl glycoside 1 1 1 1 1 1 Sorbitol 3 4 5 3 4 5 Disodium edetate 0.3 0.3 0.3 0.3 0.3 0.3 water 85.7 83.7 80.7 85.7 83.7 80.7

[0053] Preparation method:

[0054] Dissolve C6-C8 short-chain alkyl glycosides and sorbitol in 50 grams of water according to the above ratio, then add modified natural oil (SOE) to obtain mixture a; then add modified amino acid anionic surfactant and ethylenediamine Dissodium tetraacetate was dissolved in the remaining water to obtain a mixture b; the mixture b was added to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com