Fabricated building energy-saving thermal insulation wall and manufacturing and assembling method thereof

A technology for thermal insulation wall and building energy saving, applied in thermal insulation, construction, building components and other directions, can solve the problems of the impact of the structural strength of the foundation wall, increase the construction pressure, poor thermal insulation performance, etc., to reduce the risk of falling and improve the strength. , Improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

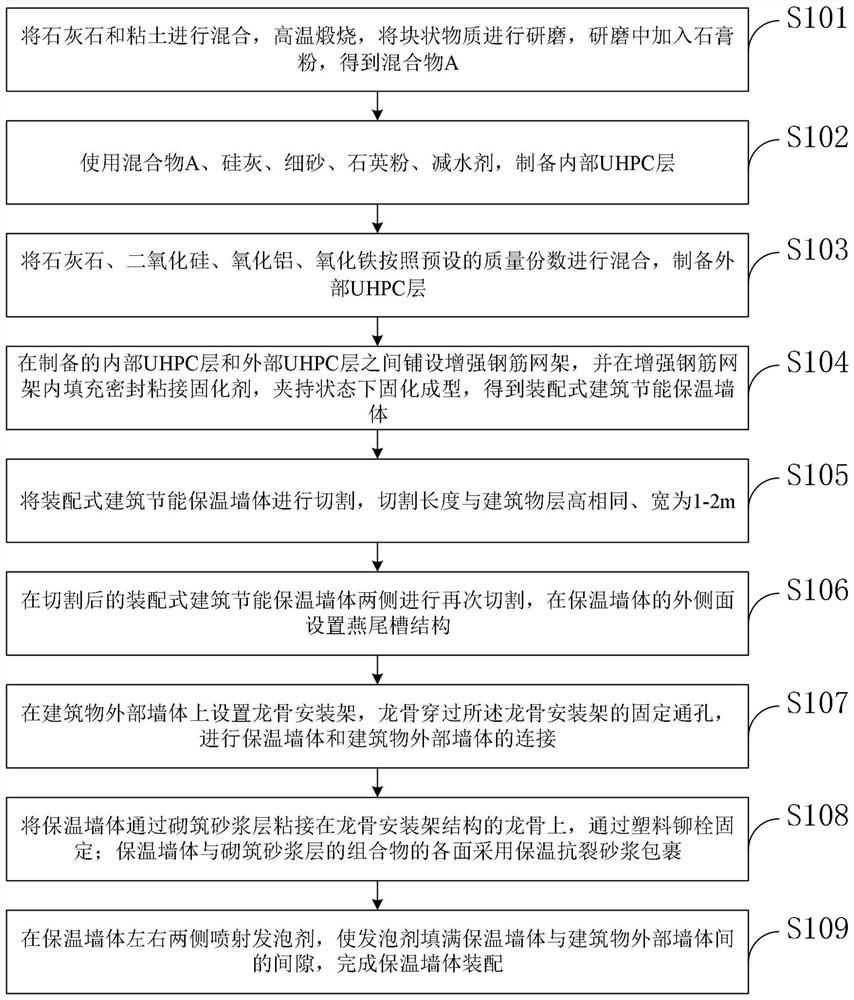

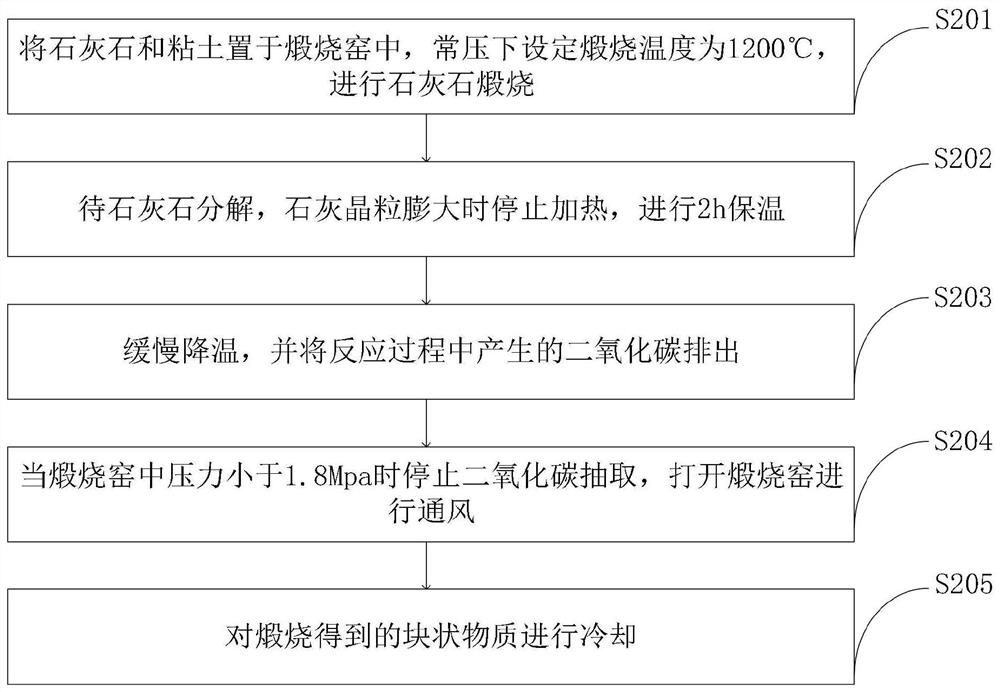

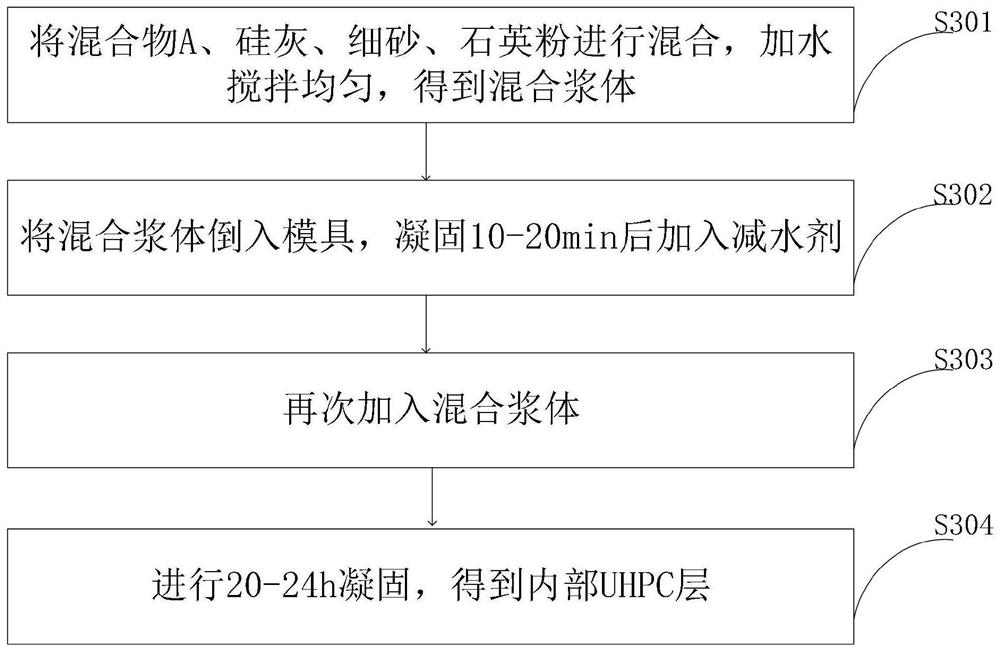

[0089] Limestone and clay are mixed, calcined at high temperature, and the blocky material is ground, and gypsum powder is added to the grinding to obtain mixture A, and the inner UHPC layer is prepared by using mixture A, silica fume, fine sand, quartz powder, and water reducer; Limestone, silica, alumina, and iron oxide are mixed according to the preset mass parts to prepare the external UHPC layer; a reinforced steel grid frame is laid between the prepared internal UHPC layer and the external UHPC layer, and the reinforced steel grid frame The interior is filled with sealing and bonding curing agent, which is cured and formed in a clamped state to obtain an energy-saving and thermal insulation wall of a prefabricated building;

Embodiment 2

[0091] Carry out the mensuration of inner UHPC layer and outer UHPC layer performance, the result is as shown in table 1:

[0092] Table 1:

[0093] 7d bending resistance 7d anti-stress 28d bending resistance 28d anti-stress Example 1 46 139 56 160

Embodiment 3

[0095] Cut the prefabricated building energy-saving thermal insulation wall, the cutting length is the same as the building floor height, and the width is 1m; cut again on both sides of the prefabricated building energy-saving thermal insulation wall, and set the dovetail on the outer side of the thermal insulation wall Groove structure; a keel installation frame is set on the external wall of the building, and the keel passes through the fixed through hole of the keel installation frame to connect the thermal insulation wall and the external wall of the building; spray hair on the left and right sides of the thermal insulation wall Foaming agent, so that the foaming agent fills the gap between the thermal insulation wall and the external wall of the building, and completes the assembly of the thermal insulation wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com