High-safety polymer battery positive plate, polymer battery and battery preparation method

A battery positive electrode and polymer technology, which is applied in the manufacture of electrolyte batteries, electrode manufacture, battery electrodes, etc., can solve the problems of reducing the energy density of materials and being unable to effectively block the contact between the positive electrode active material and the aluminum foil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

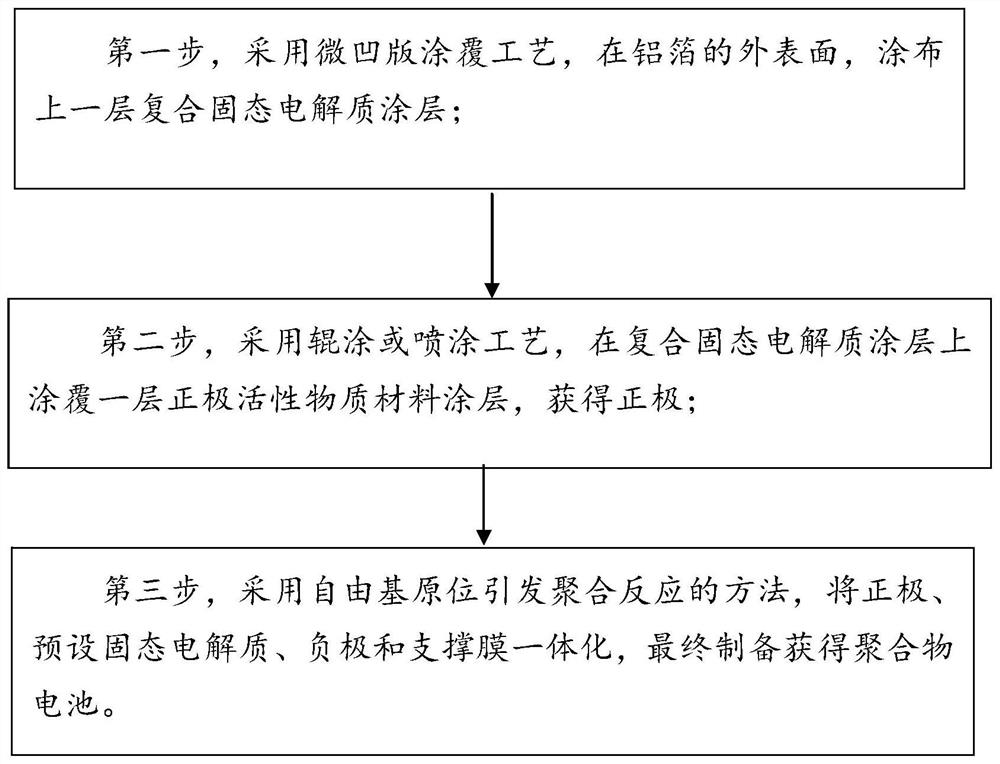

[0151] see figure 1 In order to prepare a high-safety polymer battery based on positive electrode protection provided by the present invention, the present invention also provides a method for preparing a high-safety polymer battery based on positive electrode protection, comprising the following steps:

[0152] The first step is to use a micro-gravure coating process (an existing mature process) to coat a layer of composite solid electrolyte coating on the outer surface of the aluminum foil (including the upper and lower sides and the front and rear sides);

[0153] The second step is to apply a layer of positive electrode active material coating on the composite solid electrolyte coating (specifically the outer surface) by using a roller coating or spraying process (an existing mature process) to obtain a positive electrode;

[0154] In the third step, the method of in situ initiating polymerization by free radicals (an existing mature process) is used to integrate the positiv...

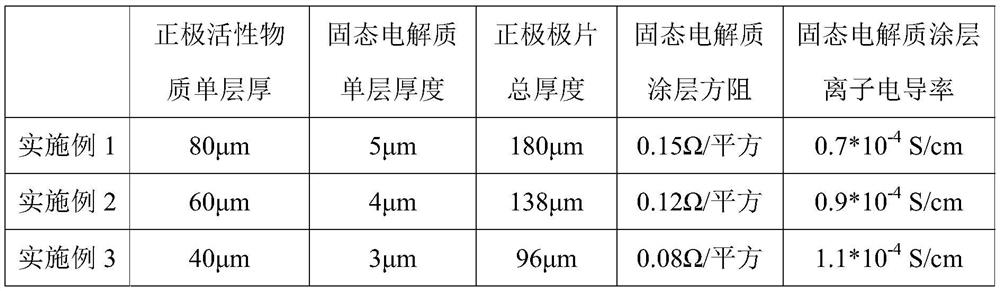

Embodiment 1

[0204] The preparation method of a high-safety polymer battery based on positive electrode protection provided by the present invention adopts a micro-gravure coating process to coat a composite solid electrolyte coating on an aluminum foil; adopts a roller coating process to coat a solid electrolyte layer Positive electrode active material coating. In situ polymerization is initiated by free radicals, and a positive electrode, a preset polymer electrolyte, a negative electrode, and a support membrane are integrated to prepare a polymer battery. The specific steps of decomposition are as follows:

[0205] The first step, solid electrolyte slurry preparation: use LLZO, CNT, PAN / PVDF, 3-methacryloxypropylmethyldiethoxysilane, LITFSI, NMP, etc. to mix evenly to prepare solid electrolyte layer coating slurry material. The percentage by weight of solid raw materials for the coating slurry is distributed as follows: LLZO is 40%, PAN is 10%, PVDF is 10%, 3-methacryloyloxypropylmeth...

Embodiment 2

[0213] The preparation method of a high-safety polymer battery based on positive electrode protection provided by the present invention adopts a micro-gravure coating process to coat the composite solid electrolyte coating on the aluminum foil; adopts a spray coating process to coat the composite solid electrolyte coating Covered with positive electrode active material coating. Using free radicals to initiate polymerization in situ, the positive electrode, solid electrolyte, negative electrode and support membrane are integrated to prepare a polymer battery. Proceed as follows:

[0214] The first step, preparation of solid electrolyte slurry: use LATP, CNT, PMMA / PVDF, vinyl-terminated polydimethylsiloxane, LiFSI, NMP, etc. to mix uniformly to prepare a solid electrolyte layer coating slurry. The coating slurry solid raw material weight percent distribution is: LATP is 40%, PMMA is 10%, PVDF is 10%, vinyl-terminated polydimethylsiloxane 19.5%, azobisisobutyronitrile 0.5%, CNT ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com