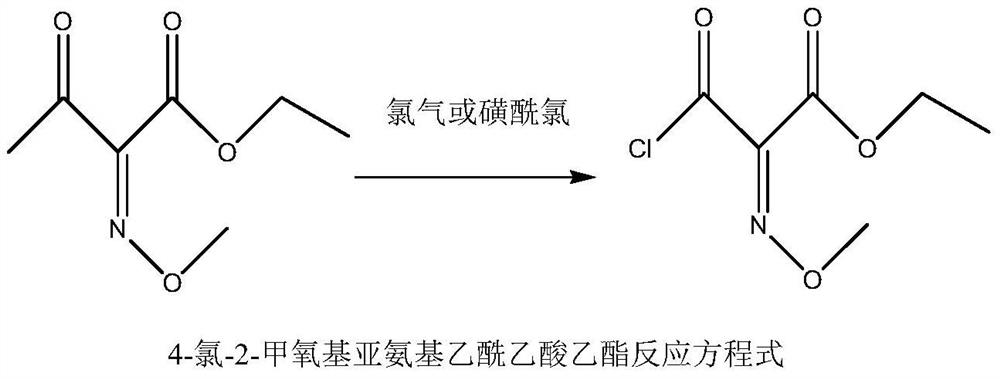

Synthesis method and device of ethyl 4-chloro-2-methoxyiminoacetoacetate

A technology of ethyl methoxyiminoacetoacetate and synthesis method, applied in organic chemistry, oxime preparation, etc., can solve the problems of cumbersome post-treatment, high production cost, cumbersome waste water treatment, etc., to speed up the reaction speed and improve the utilization efficiency, improving reaction selectivity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1500kg (7.36kmol) of methanol solution 1500kg (7.36kmol) of 85% ethyl 2-methoxyiminoacetoacetate that has absorbed the reaction tail gas is added in the reactor, controlled by the DSC program, and the total amount of liquid chlorine feeding is controlled by the regulating valve It is 575kg (8.1kmol). In the first hour, 35% of the total liquid chlorine was introduced, and the temperature control was controlled at 28-30°C; in the second hour, 35% of the liquid chlorine was introduced, and the temperature was controlled at 25-27°C; 20%, the temperature is controlled at 23-25°C; in the fourth hour, 10% of the total liquid chlorine is introduced, and the temperature is controlled at 20-22°C. After the feed was completed, heat preservation and degassing for 4 hours to obtain ethyl 4-chloro-2-methoxyiminoacetoacetate, which was directly used in the next reaction without recovering the solvent. The liquid phase component content is 91.5%, and the yield is 92.3%. The hydrogen ...

Embodiment 2

[0036] Add 1600kg (7.39kmol) of ethanol solution 1600kg (7.39kmol) of 80% ethyl 2-methoxyiminoacetoacetate that has absorbed the reaction tail gas into the reactor, control the total amount of liquid chlorine through the control valve through the DSC program control It is 525kg (7.39kmol). In the first hour, 35% of the total liquid chlorine is fed, and the temperature control is controlled at 28-30°C; in the second hour, 30% of the liquid chlorine is fed, and the temperature is controlled at 25-27°C; 20%, the temperature is controlled at 23-25°C; in the fourth hour, 15% of the total liquid chlorine is introduced, and the temperature is controlled at 20-22°C. After the feeding, heat preservation and degassing for 3 hours to obtain ethyl 4-chloro-2-methoxyiminoacetoacetate with a liquid phase component content of 89.5% and a yield of 90.1%. The hydrogen chloride and excess chlorine gas produced by the reaction are absorbed by the solution of ethyl 2-methoxyiminoacetoacetate and...

Embodiment 3

[0038] 1600kg (7.39kmol) of ethanol solution 1600kg (7.39kmol) of 80% ethyl 2-methoxyiminoacetoacetate that has absorbed the tail gas of the reaction is added in the reactor, controlled by the DSC program, and the total amount of liquid chlorine feeding is controlled by the regulating valve It is 629kg (8.86kmol). In the first hour, 30% of the total liquid chlorine is fed, and the temperature control is controlled at 28-30°C; in the second hour, 30% of the liquid chlorine is fed, and the temperature is controlled at 25-27°C; in the third hour, 30% of the total liquid chlorine is fed. 20%, the temperature is controlled at 23-25°C; in the fourth hour, 20% of the total liquid chlorine is introduced, and the temperature is controlled at 20-22°C. After the feeding, heat preservation and degassing for 4 hours to obtain ethyl 4-chloro-2-methoxyiminoacetoacetate with a liquid phase component content of 90.4% and a yield of 91.5%. The hydrogen chloride and excess chlorine gas produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com