A kind of preparation method of composite flame retardant for fireproof heat preservation decorative board

A composite flame retardant, fireproof and thermal insulation technology, applied in fireproofing, construction, building components, etc., can solve the problems of unfavorable use, toxicity, etc., and achieve the effects of uniform molding, improved flame retardancy, and uniform foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

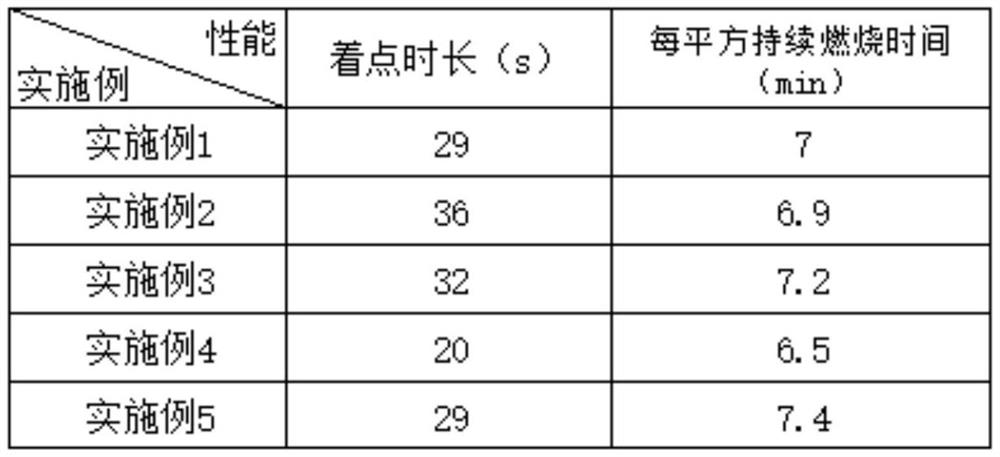

Examples

preparation example Construction

[0024] A preparation method for a composite flame retardant for a fireproof heat preservation decorative board, said method comprising the following steps:

[0025] (a) Pulverizing the hydrated silica with a ball mill to obtain hydrated silica powder, adding an acidic solution to the hydrated silica powder, stirring for 3.5 hours, filtering to remove incomplete reactants, adjusting the pH value to 5.5-6, and obtaining a mixed liquid;

[0026] (b) heating the mixed liquid to 40°C-45°C, adding zinc carbonate to the mixed liquid, and continuously stirring for 30min-40min to obtain a mixed liquid containing zinc carbonate;

[0027] (c) adding aluminum hydroxide particles, silicon dioxide particles and magnesium hydroxide particles to the mixed solution containing zinc carbonate, and continuously stirring for 25min-40min to obtain a silicon-magnesium-based mixed solution;

[0028] (d) adding absolute ethanol to the sodium silicate, stirring evenly, adding an acidic solution dropwis...

Embodiment 1

[0040] Through the above method, 30 parts of hydrated silica, 12 parts of zinc carbonate, 8 parts of aluminum hydroxide particles, 10 parts of silicon dioxide particles, 5 parts of magnesium hydroxide particles, and 45 parts of sodium silicate.

Embodiment 2

[0042] Through the above method, 40 parts of hydrated silica, 18 parts of zinc carbonate, 12 parts of aluminum hydroxide particles, 15 parts of silicon dioxide particles, 8 parts of magnesium hydroxide particles, and 65 parts of sodium silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com