Dual-furnace type powder flying melting glass kiln

A technology for melting glass and furnace type, applied in the direction of furnace type, glass production, glass furnace equipment, etc., can solve the problems of reducing raw materials, reducing production, economic loss, etc., and achieve the effect of avoiding melting temperature and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

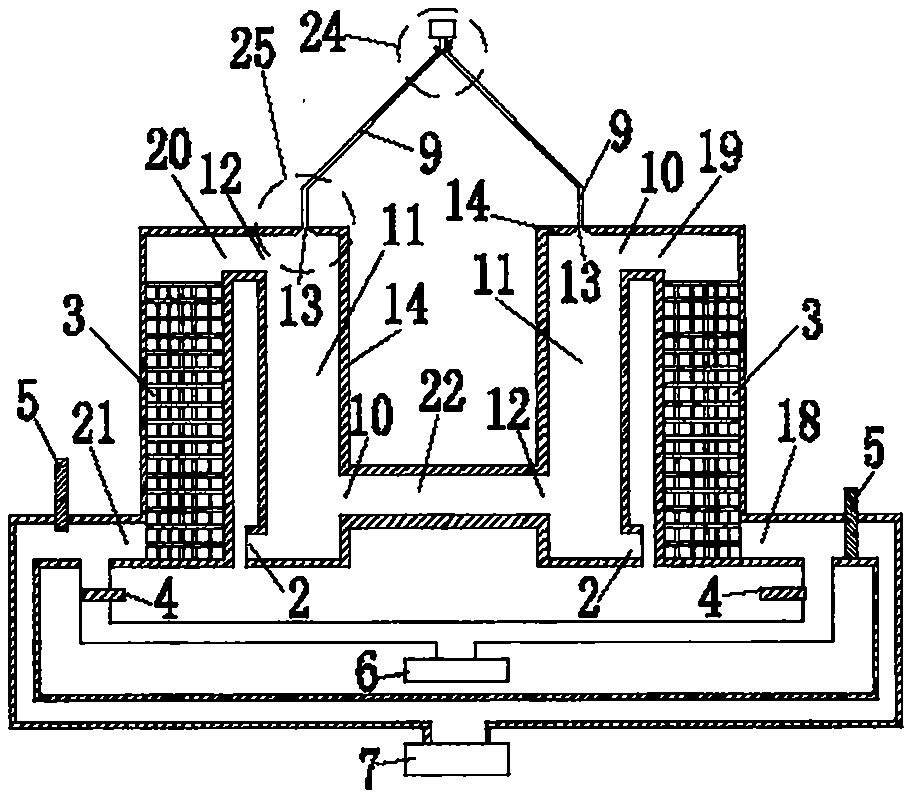

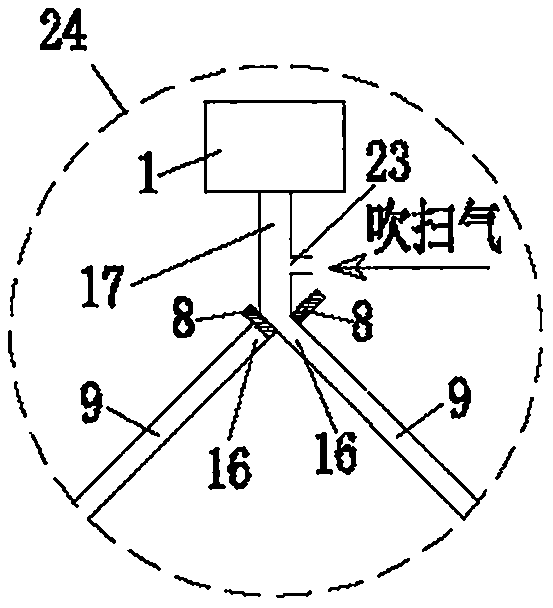

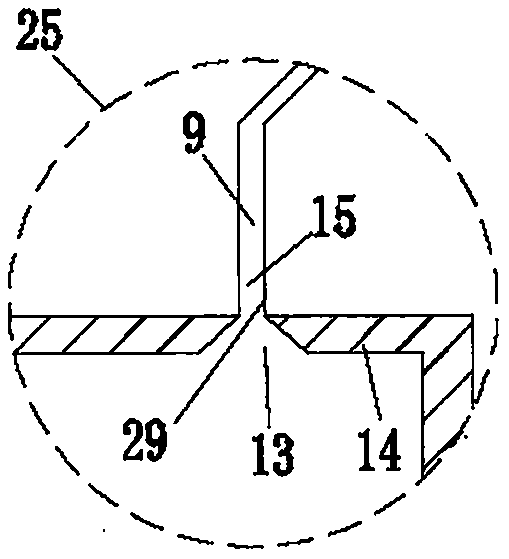

[0040] see figure 1 , figure 1 Details of the areas indicated by dashed circles 24, 25 in figure 2 , 3 . figure 1 Shown is a double-furnace powder flying melting glass furnace, which includes two melting furnaces, raw material feeding equipment 1 and an oxygen-containing gas preheating system. The oxygen-containing gas preheating system includes two regenerators 3, Two gas reversing gates 4, two flue gas reversing gates 5, oxygen-containing gas input device 6 and flue gas discharge device 7; one of the two regenerators 3 is used for preheating oxygen-containing gas , the other is used to cool high-temperature waste gas, the regenerator 3 for preheating oxygen-containing gas has an oxygen-containing gas inlet 18 and a preheated gas outlet 19, and the regenerator 3 for cooling high-temperature waste gas has a high-temperature waste gas Inlet 20 and cold exhaust outlet 21.

[0041] The connection mode of the components of the above-mentioned oxygen-containing gas preheating...

Embodiment 2

[0047] see figure 1 , 4 ,Will figure 1 The area indicated by the dashed circle 24 in Figure 4 The area represented by the dotted line circle 26 is replaced to form a double-furnace type powder flying melting glass furnace, which has basically the same structure as that of Embodiment 1, except that the purge gas input port 23 provided on the common feeding pipeline 17 A purge gas input pipeline 27 is connected; a valve 28 is installed on the purge gas input pipeline 27 .

Embodiment 3

[0049] see Figure 5 , Figure 5 For details of the area indicated by the dashed circle 30 in Figure 6 . Figure 5 Shown is a double-furnace powder flying melting glass furnace, which includes two melting furnaces and the same oxygen-containing gas preheating system as in Example 1, the difference is that:

[0050] Described melting furnace comprises raw material feeding device 1, air inlet 10, gas outlet 12, feed inlet 13 and raw material feed pipeline 9; The raw material feeding pipeline 9 of described melting furnace comprises outlet end 15 and inlet end 16, and its outlet End 15 communicates with the feed port 13 of the melting furnace, and its inlet port 16 communicates with the raw material feeding equipment 1 of the melting furnace; the preheated gas outlet 19 communicates with the inlet 10 of a melting furnace, and the raw material feeding of the melting furnace The equipment 1 is in the state of starting feeding, the gas outlet 12 of the furnace communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com