Antifoam composition and admixture for hydraulic composition including same

A technology for a composition and a defoaming agent, applied in the field of a mixture for a hydraulic composition and a defoaming agent composition, can solve the problems of reduced strength of the hardened body, damage to the appearance, uneven filling, etc., and achieve excellent defoaming properties. , The surface is beautiful, the effect of less bubble marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

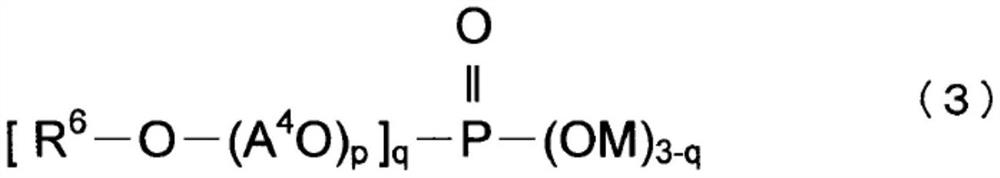

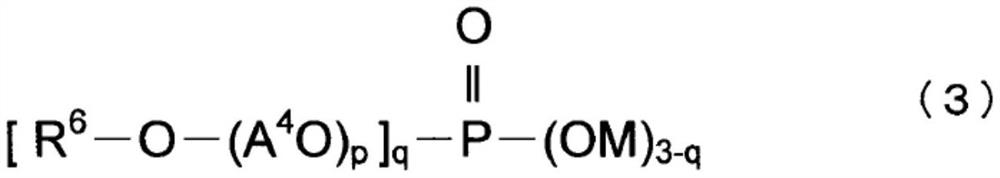

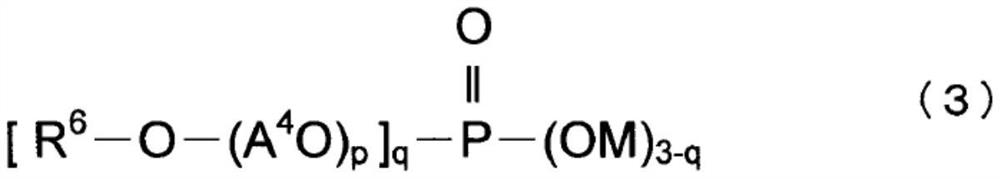

Method used

Image

Examples

manufacture example 1

[0128] Put 202g of stearyl alcohol and 4g of 96% potassium hydroxide into a stainless steel high-pressure reactor equipped with a thermometer, a stirrer, a pressure gauge, and a nitrogen inlet pipe, replace the reaction vessel with nitrogen, and heat to 150°C under a nitrogen atmosphere . In a state where 150° C. was maintained under a safe pressure, 182 g of ethylene oxide was introduced into the reactor over 5 hours, and the temperature was maintained for 1 hour. Then, it was cooled to 120° C., and kept at 120° C. under a safe pressure, 1088 g of propylene oxide was introduced into the reactor for 10 hours, and the temperature was maintained for 4 hours to complete the alkylene oxide addition reaction to obtain 1492 g Polyoxyethylene polyoxypropylene glycol monostearyl ether (compound A1).

manufacture example 2

[0130] 200g of 1-tridecyl alcohol and 2.8g of 96% potassium hydroxide are charged into a stainless steel high-pressure reactor equipped with a thermometer, a stirrer, a pressure gauge, and a nitrogen gas inlet pipe, and nitrogen replacement is carried out in the reaction vessel. Heat to 150°C. Then, 182 g of ethylene oxide was introduced into the reactor over 2 hours while maintaining 150° C. under a safe pressure, and the temperature was maintained for 1 hour. Thereafter, it was cooled to 120° C., and 1177 g of propylene oxide was introduced into the reactor over 10 hours while maintaining the temperature at 120° C. under a safe pressure, and the temperature was maintained for 4 hours. Then, it was heated again to 150° C., and 200 g of ethylene oxide was introduced into the reactor for 2 hours while maintaining 150° C. under a safe pressure, and the temperature was maintained for 1 hour to complete the alkylene oxide addition reaction. 220 g of 65% stearic acid and 0.6 g of ...

manufacture example 3

[0132] Put 216g of oleic acid and 0.2g of 96% potassium hydroxide into a stainless steel high-pressure reactor equipped with a thermometer, a mixer, a pressure gauge, and a nitrogen inlet pipe, replace the reaction vessel with nitrogen, and heat to 170°C under a nitrogen atmosphere . Then, under a safe pressure at 170°C, 270 g of ethylene oxide was introduced into the reactor for 5 hours, and the temperature was maintained for 1 hour to obtain 486 g of polyethylene glycol oleate (compound A3) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com