Thermoplastic polyurethane yarn and fabric manufactured therefrom

A thermoplastic polyurethane, raw yarn technology, applied in the manufacture of single-component polyurethane rayon, yarn, rayon, etc., can solve the problems of difficult continuous production lines, slow crystallization speed of thermoplastic polyurethane, and inability to stretch and recover, achieving increased Elongation, the effect of improving stretch and recovery properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] When producing a thermoplastic polyurethane raw yarn, the use of succinate and nano-silica increases the crystallization rate during cooling and stretching, and this will be specifically described as an example.

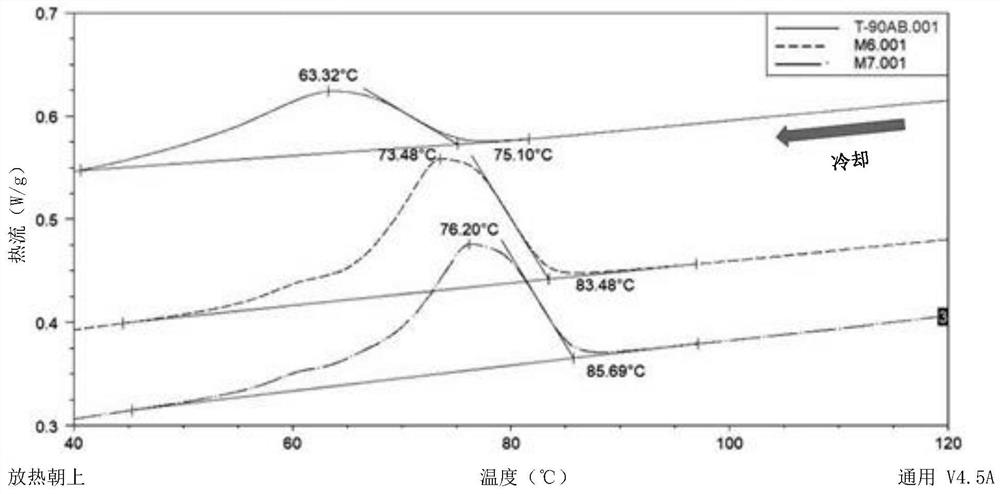

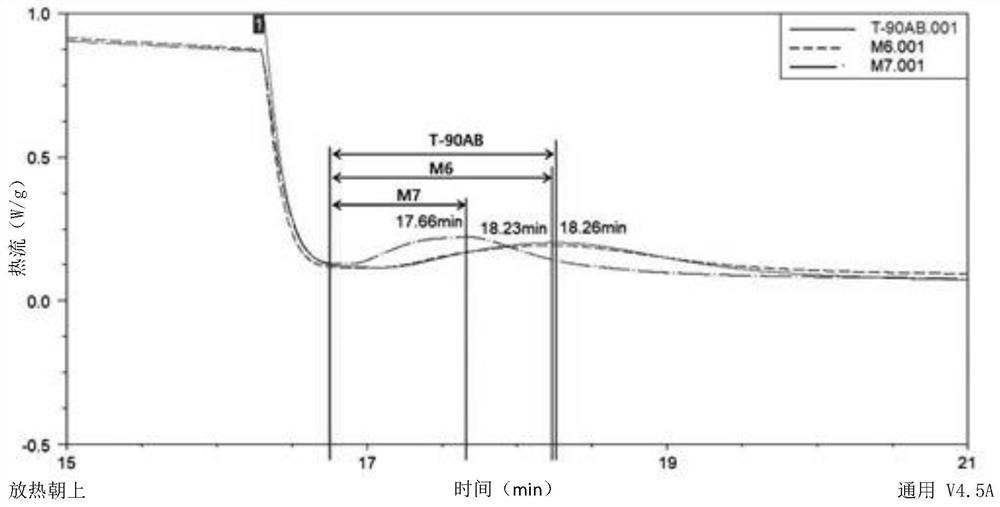

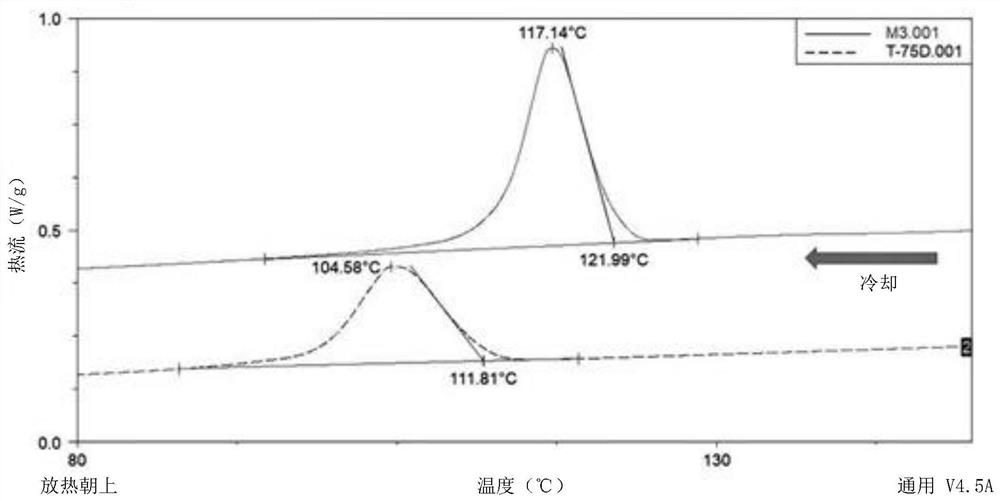

[0055] Figure 1 to Figure 4 The value obtained by analyzing the crystallization rate (Crystallization rate) by differential scanning calorimetry (DSC) is represented by a graph. Conditions for analyzing the crystallization rate by DSC are as follows.

[0056] 1. Heating from 25°C to 250°C at a rate of 10°C / min (Heating from 25°C to 250°C, Rate 10°C / min).

[0057] 2. Equilibrate for 2 minutes (Equilibrium for 2 minutes).

[0058] 3. Cooling to crystallization temperature, the rate is 10°C / min (Cooling to Crystallization temperature, Rate 10°C / min)

[0059] 4. Isotherm for 15 minutes.

[0060] *Crystallization temperature

[0061] T-90AB, M6, M7: 90°C

[0062] T-75D, M3: 150°C

[0063]In this case, T-90AB is a 90A durometer, 0% succinate, and 61% adipate...

Embodiment 2

[0069] Tables 1 to 6 disclose the mixing ratio of each composition when TPU with a hardness of 75D is used to prepare the thermoplastic polyurethane raw yarn of the present invention. That is, the following table specifically discloses the elongation and processability of thermoplastic polyurethane raw yarns when the succinate content and the nano silica content are adjusted. The elongation of the thermoplastic polyurethane raw yarn was measured to be the same value for both multifilament and monofilament. In this case, the elongation refers to the stretching and recovery function of the thermoplastic polyurethane raw yarn, and the processability refers to the state of yarn spinning during the cooling and stretching process during the melt extrusion process when preparing the thermoplastic polyurethane raw yarn.

[0070] Conventional thermoplastic polyurethane compositions shown in the following tables, specifically, the respective contents of isocyanate (isocyanate) and ethyl...

Embodiment 3

[0088] Table 7 to Table 13 disclose the mixing ratio of each composition when TPU with a hardness of 60D is used to prepare the thermoplastic polyurethane raw yarn of the present invention. That is, the following table specifically reveals the elongation and processability of the thermoplastic polyurethane raw yarn when the succinate ester content and the nano silica content are adjusted.

[0089] Table 7

[0090]

[0091] Table 8

[0092]

[0093] Table 9

[0094]

[0095] Table 10

[0096]

[0097] Table 11

[0098]

[0099]

[0100] Table 12

[0101]

[0102] Table 13

[0103]

[0104] As can be seen from the above Tables 7 to 13, when the hardness of thermoplastic polyurethane is 60D, if less than 5% of succinate is used, it is difficult to produce monofilament yarn and multifilament yarn due to the low crystallization speed. When the content is 5-40%, monofilament yarn and multifilament yarn can be produced smoothly due to the increase of cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com