Preparation method of prussian white analogue with low defects and low water content

An analog, low-defect technology, applied in the direction of ferricyanide, metal cyanide, etc., can solve the problems of high water content and many defects, and achieve the effects of increasing active potassium content, good thermal stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a Prussian white analog with low defects and low water content, comprising the following steps:

[0035] Step 1: Preparation of Solution A

[0036] Weigh 2.11g K 4 Fe(CN) 6 ·3H 2 O was dissolved in 100mL of water and stirred until dissolved to obtain solution A.

[0037] Step 2: Preparation of Solution B

[0038] Weigh 0.85g MnSO 4 ·H 2 O and 2.02g EDTA-2K 2H 2 O was dissolved in 100mL of water and stirred until dissolved to obtain solution B.

[0039] Step 3: Under nitrogen atmosphere, add solution B to solution A while stirring to produce a white precipitate. After adding solution B, let it stand for 24 hours, filter and wash the resulting white precipitate, and dry it at 80°C for 24 hours. A Prussian white analogue with low defects and low water content was obtained as the final target product.

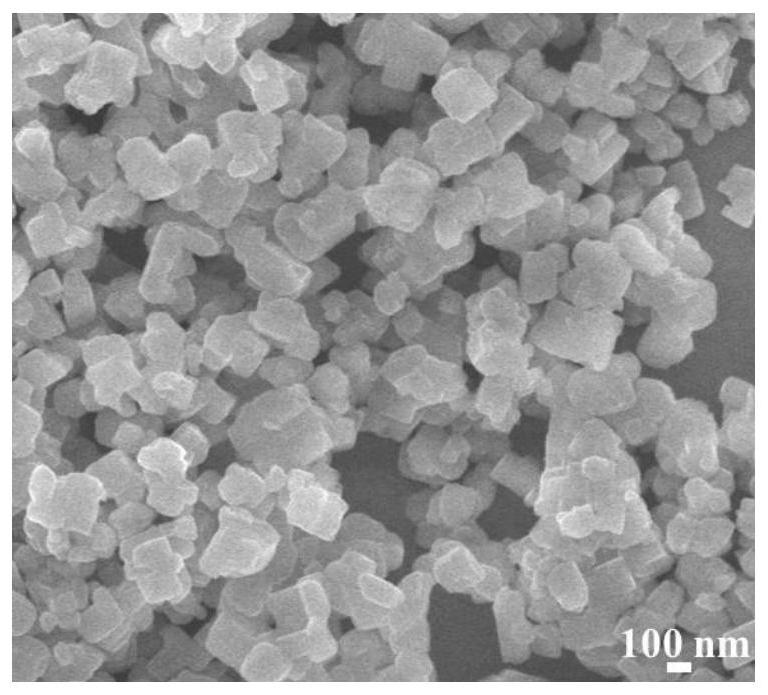

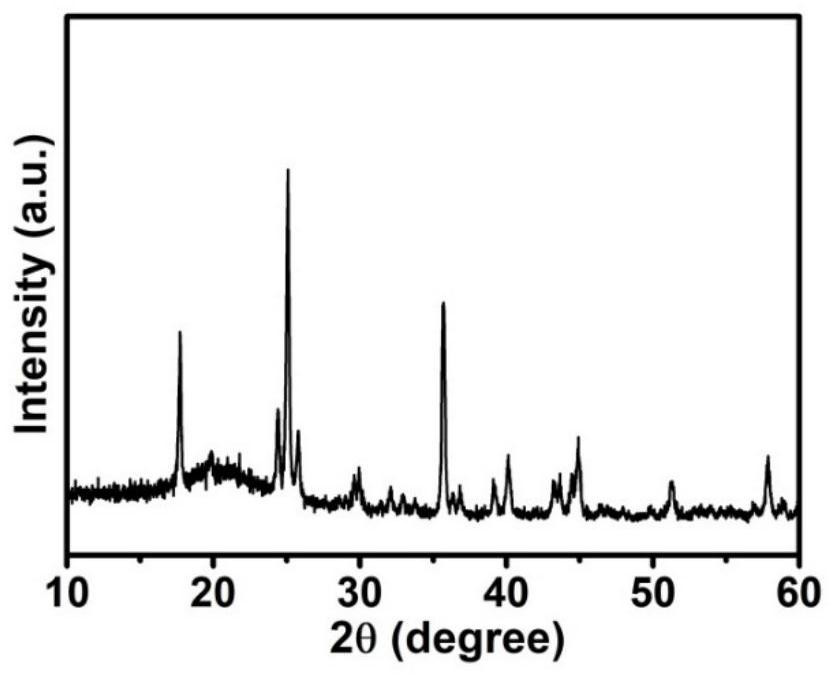

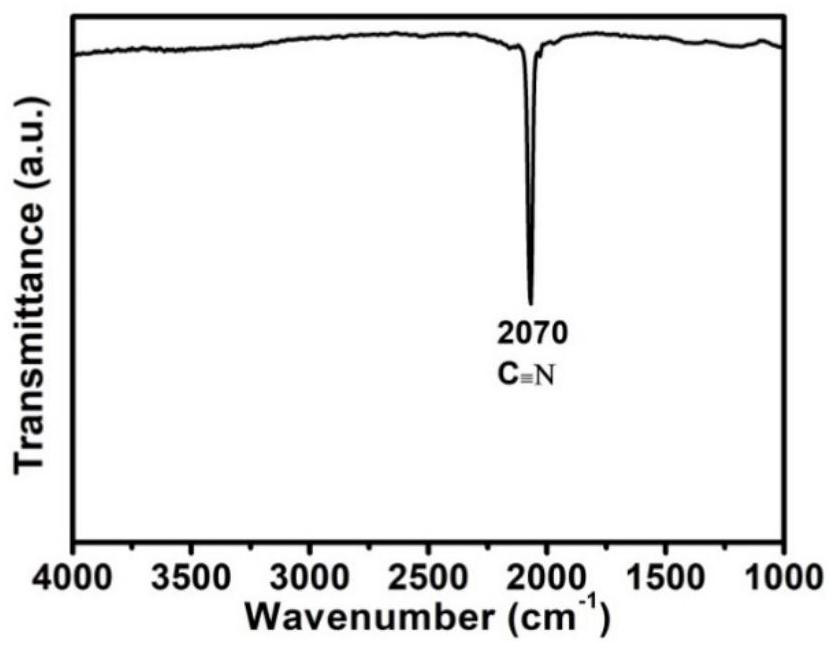

[0040] Step 4: Characterize the morphology of the prepared Prussian white analog using scanning electron microscope (SEM), X-ray diffractomet...

Embodiment 2

[0043] Step 1 is the same as Example 1

[0044] Step 2: Preparation of Solution B

[0045] Weigh 0.99g MnCl 2 4H 2 O and 2.02g EDTA-2K 2H 2 O was dissolved in 100mL of water and stirred until dissolved to obtain solution B.

[0046] Steps 3 and 4 are the same as in Example 1

[0047] The Prussian white analog prepared in this example is the same as that in Example 1, and the Prussian white analog has the characteristics of low defects and low water content.

Embodiment 3

[0049] Step 1 is the same as Example 1

[0050] Step 2: Preparation of Solution B

[0051] Weigh 0.99g MnCl 2 4H 2 O and 1.86g EDTA-2Na·2H 2 O was dissolved in 100mL of water and stirred until dissolved to obtain solution B.

[0052] Steps 3 and 4 are the same as in Example 1

[0053] The Prussian white analog prepared in this example is the same as that in Example 1, and the Prussian white analog has the characteristics of low defects and low water content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com