Low dielectric constant glass fiber and preparation method thereof

A low dielectric constant, glass fiber technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

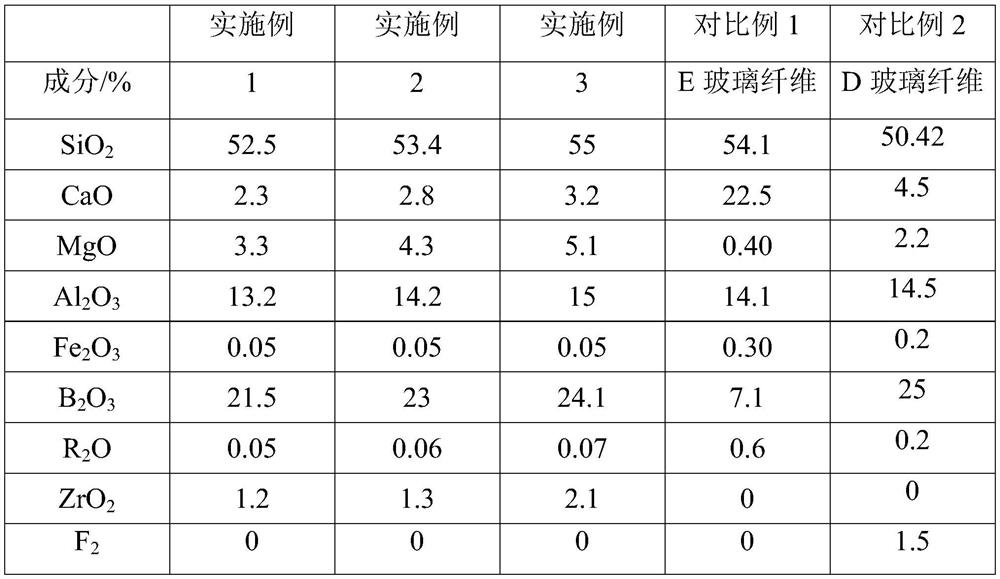

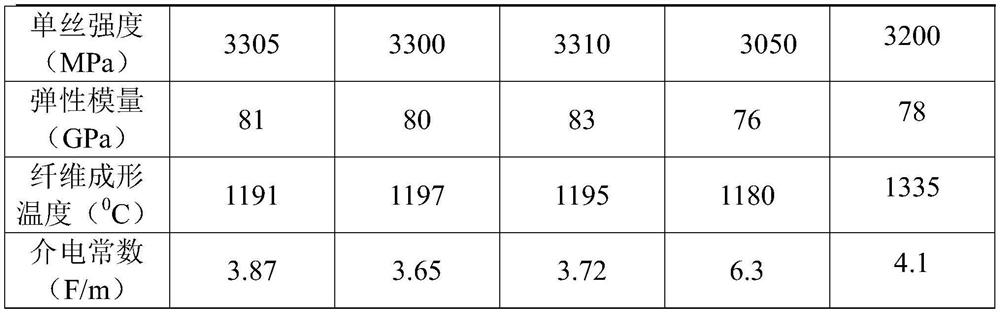

[0034] The invention provides a method for preparing glass fiber with low dielectric constant. The raw materials include the following components in parts by weight: 52-60 parts of quartz sand, 20-25 parts of aluminum hydroxide, 2-4 parts of lime, 2 parts of magnesium hydroxide ~5 parts, zirconium powder 1~3 parts, borax 32~36 parts.

[0035]The preparation method comprises the following steps: (1) weighing: weighing quartz sand, aluminum hydroxide, lime, magnesium hydroxide, zirconium powder, and borax according to the proportion by weight; (2) mixing: mixing the weighed The components are added to the mixer and mixed; (3) Melting: the uniformly mixed raw materials are transported to the kiln head bin, and then sent to the pool kiln for melting. The melting temperature is 1100-1700 ° C and the time is 25 -30min to obtain molten glass; (4) molding: the melted glass passes through the channel to make glass balls; (5) wire drawing: the glass balls are sent to the platinum crucib...

Embodiment 1

[0039] Weigh 53kg of quartz sand, 22kg of aluminum hydroxide, 2.5kg of lime, 2.2kg of magnesium hydroxide, 1.5kg of zirconium powder and 32kg of borax, mix them evenly in the mixer, and transport them to the kiln head warehouse, and then send them into the pool kiln for melting The melting temperature is 1200°C, and the melting time is 25 minutes. The molten glass is passed through the passage to make glass balls, and then drawn through a platinum crucible furnace to obtain a finished low dielectric constant glass fiber. The glass in the platinum crucible furnace The volume of the ball is 1 / 2 of that of the platinum crucible furnace, and the drawing temperature is 1200°C.

[0040] The obtained low dielectric constant glass fiber contains the following components: SiO 2 52.5%, CaO 2.3%, MgO3.3%, Al 2 o 3 13.2%, B 2 o 3 21.5%, ZrO 2 1.2%, Fe 2 o 3 0.05%, K 2 O 0.05% and other unavoidable impurities.

Embodiment 2

[0042] Weigh 54.5kg of quartz sand, 23kg of aluminum hydroxide, 2kg of lime, 3.2kg of magnesium hydroxide, 1.7kg of zirconium powder and 33.5kg of borax, mix them evenly in the mixer and transport them to the kiln head warehouse, and then send them into the pool kiln for further processing. Melting, the melting temperature is 1500°C, and the melting time is 28 minutes. The molten glass is passed through the passage and made into glass balls, and then drawn through a platinum crucible furnace to obtain a finished low dielectric constant glass fiber. Among them, the platinum crucible furnace The volume of the glass ball is 1 / 3 of the platinum crucible furnace, and the drawing temperature is 1200°C.

[0043] The obtained low dielectric constant glass fiber contains the following components: SiO 2 53.4%, CaO 2.8%, MgO 4.3%, Al 2 o 3 12.2%, B 2 o 3 23%, ZrO 2 1.3%, Fe 2 o 3 0.05%, Na 2 O 0.06% and other unavoidable impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com