Preparation method of metrafenone

A technology of metrafenone and chlorobenzene, applied in the field of organic synthetic chemistry, can solve problems such as low total yield, difficult purification and separation, and difficult industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Embodiment: the concrete steps of the preparation method of a kind of metrafenone of the present invention are as follows:

[0048] (1) Diazotization reaction:

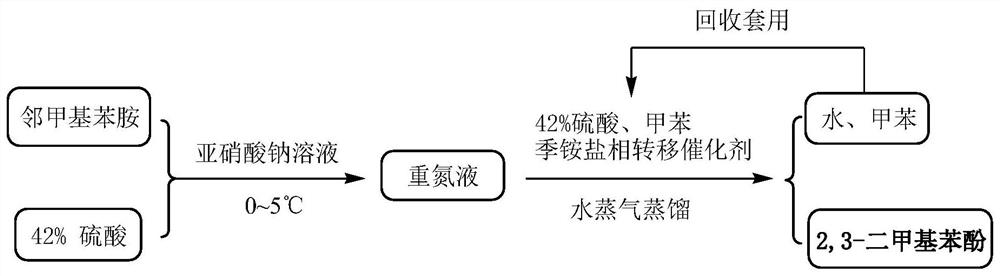

[0049] Depend on figure 1 As can be seen from the diazotization reaction process flow chart shown, the temperature of the mixed solution of 400kg of 42wt% sulfuric acid and 128.8kg of 2,3-dimethylaniline is lowered to -5~0°C, and then dropwise below the liquid surface Add 234.6kg of pre-prepared 30wt% sodium nitrite solution and stir well to obtain a diazo solution, which is stored below 0-5°C for direct use in the next step. Attention should be paid to the safety of diazotization in this step.

[0050] (2) Hydrolysis reaction:

[0051] Depend on figure 1 Shown hydrolysis reaction process flow sheet finds out, to the diazonium liquid of step 1 gained, add the sulfuric acid 534kg of boiling 42wt%, toluene 272kg and 2mmol quaternary ammonium salt phase-transfer catalyst (0.68kg tetrabutyl ammonium bromide) mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com