Antibacterial polypropylene melt-blown material as well as preparation method and application thereof

An antibacterial polypropylene and polypropylene meltblown technology, applied in the field of textile materials, can solve problems such as side reactions and polymer molecular weight reduction, and achieve the effect of durable antibacterial function and renewable antibacterial function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of antibacterial polypropylene melt-blown material, comprises the following steps:

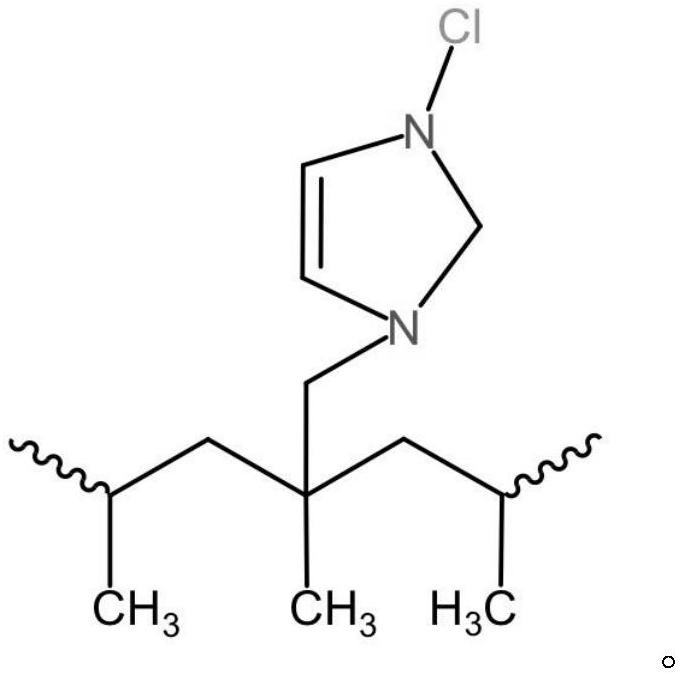

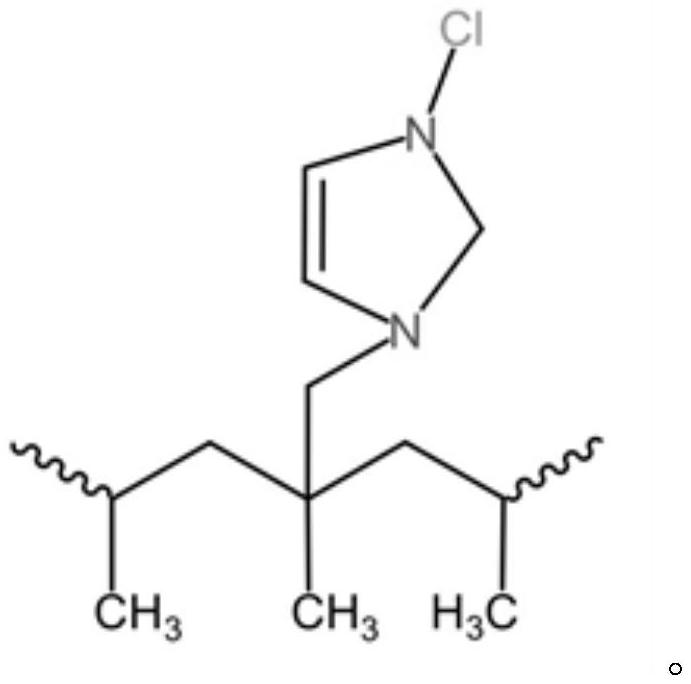

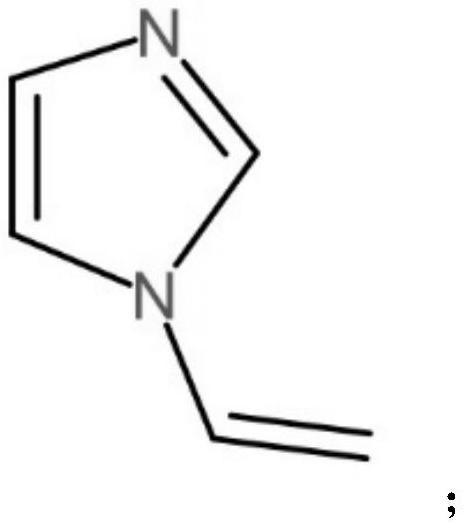

[0032] S1. According to the predetermined ratio, dry mix the polypropylene masterbatch, 1-vinylimidazole and peroxide initiator for 2 to 10 minutes to obtain the mixture; then quickly introduce the mixture into the preheating chamber within the predetermined time, under nitrogen Under a protective atmosphere, carry out a modification reaction of polypropylene to obtain a modified product;

[0033] S2, freezing the modified product prepared in step S1 in an ice-water bath, and preparing the frozen modified product into modified particles with a particle size of less than 5 mm;

[0034] S3, dissolving the modified particles prepared in step S2 in boiling toluene according to a predetermined ratio to obtain a mixed hot solution, and performing a thermal reaction for 20 to 40 minutes;

[0035] S4, drop the mixed hot solution after the rea...

Embodiment 1

[0050] Embodiment 1 of the present invention provides a kind of preparation method of antibacterial polypropylene melt-blown material, comprises the following steps:

[0051] S1, the polypropylene masterbatch, 1-vinylimidazole with a concentration of 400mpm and the peroxide initiator 2,5-dimethyl-2,5-di-tert-butylperoxy-3-hexyl with a concentration of 10mpm Alkyne (DTBHY) was dry-mixed for 5 min to obtain a mixture with a total mass of 40 g; then the mixture was quickly introduced into the preheating chamber within 0.5 min, and heated at 200 ° C on a Brabender Plasti-Corder ATR (Brabender plasticizer). The polypropylene modification reaction was carried out at 50 rpm for 5 min, and nitrogen was blown over the mixing chamber so that the reaction was carried out under a nitrogen atmosphere to prevent oxidation during the reaction.

[0052] S2, freezing the modified product prepared in step S1 in an ice-water bath, and preparing the frozen modified product into modified particles...

Embodiment 2-5

[0075] The difference with embodiment 1 is: the difference of antibacterial monomer 1-vinylimidazole and peroxide initiator DTBHY concentration, other steps are all identical with embodiment 1, repeat no more at this.

[0076] Table 1 is parameter setting and its performance parameter in embodiment 1-5

[0077]

[0078] Combining with Table 1, it can be seen that the effect of antibacterial monomer 1-vinylimidazole on the antibacterial properties of antibacterial polypropylene melt-blown materials is: when the weight of polypropylene (PP), antibacterial monomer and initiator is 40g, the antibacterial monomer is 150-450 mpm (moles per million parts of PE), the obtained antibacterial polypropylene melt-blown material has the best performance.

[0079] The effect of the peroxide initiator on the antibacterial properties of antibacterial polypropylene melt-blown materials is: when the weight of PP, antibacterial monomer and initiator is 40g, the peroxide initiator is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com