A kind of method and product for removing beany flavor from soybean meal and soybean dietary fiber based on Poria cocos fermentation

A technology of soybean dietary fiber and Poria cocos, which is applied in the directions of food ingredients, food drying, and food ingredients as odor modifiers, etc., can solve problems such as reducing the activity of lipoxygenase, and achieve fresh flavor, improved overall acceptance, and broad application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

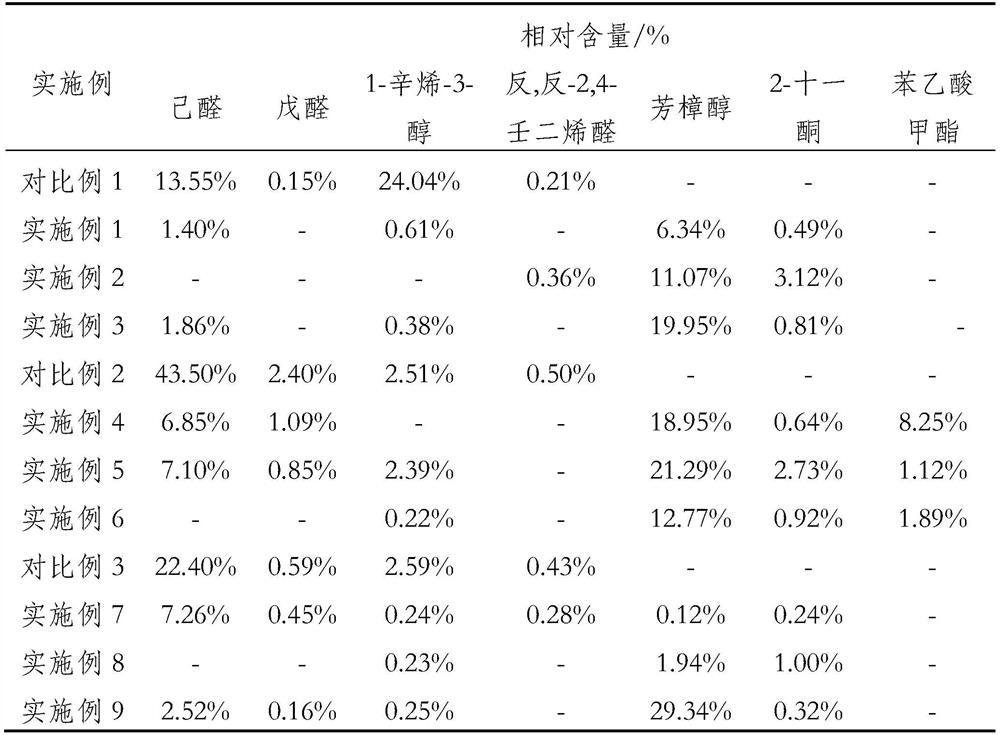

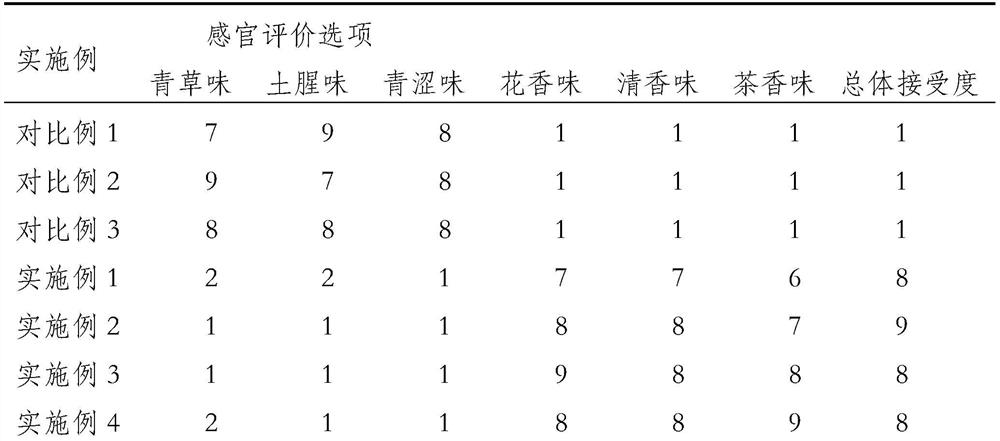

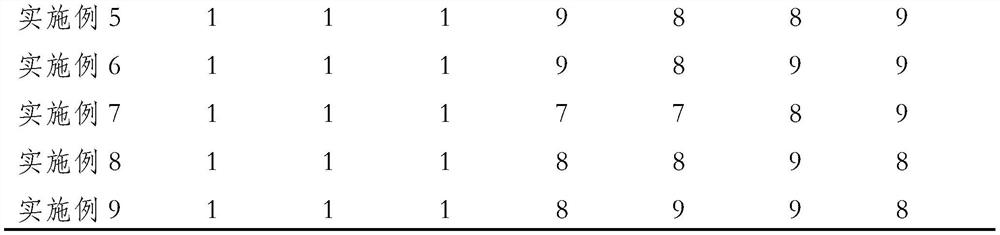

Examples

Embodiment 1

[0027] This embodiment provides a method based on the fermentation of Poria cocos bacteria to remove the beany smell of soybean meal, including:

[0028] (1) Grinding the soybean meal with a fineness of 180 mesh to obtain the crushed raw material.

[0029] (2) Take an appropriate amount of crushed soybean meal raw material, add deionized water according to 12 times its mass and mix evenly to prepare a soybean meal dietary fiber matrix.

[0030] (3) In the step (2), after the matrix was sterilized at 121° C. for 20 minutes, Poria cocos strains were inoculated, and the inoculation amount was 10% of the mass of the matrix after sterilization, to obtain a fermented soybean meal dietary fiber matrix.

[0031] (4) In the step (3), the substrate is fermented and cultured in aerobic ventilation for 3 days at a temperature of 26° C. and a pH of 6.

[0032] (5) The product in the step (4) is thermally sterilized, kept at a temperature of 95° C. for 30 seconds, and spray-dried to obtain...

Embodiment 2

[0034] This embodiment provides a method based on the fermentation of Poria cocos bacteria to remove the beany smell of soybean meal, including:

[0035] (1) Grinding the soybean meal with a fineness of 180 mesh to obtain the crushed raw material.

[0036] (2) Take an appropriate amount of crushed soybean meal raw material, add deionized water according to 12 times its mass and mix evenly to prepare a soybean meal dietary fiber matrix.

[0037] (3) In the step (2), after the matrix was sterilized at 121° C. for 20 minutes, Poria cocos strains were inoculated, and the inoculation amount was 10% of the mass of the matrix after sterilization, to obtain a fermented soybean meal dietary fiber matrix.

[0038] (4) In the step (3), the substrate is fermented and cultured in aerobic ventilation for 5 days at a temperature of 26° C. and a pH of 6.

[0039] (5) The product in the step (4) is thermally sterilized, kept at a temperature of 95° C. for 20 minutes, and spray-dried to obtain...

Embodiment 3

[0041] This embodiment provides a method based on the fermentation of Poria cocos bacteria to remove the beany smell of soybean meal, including:

[0042] (1) Grinding the soybean meal with a fineness of 180 mesh to obtain the crushed raw material.

[0043] (2) Take an appropriate amount of crushed soybean meal raw material, add deionized water according to 12 times its mass and mix evenly to prepare a soybean meal dietary fiber matrix.

[0044] (3) In the step (2), after the matrix was sterilized at 121° C. for 20 minutes, Poria cocos strains were inoculated, and the inoculation amount was 10% of the mass of the matrix after sterilization, to obtain a fermented soybean meal dietary fiber matrix.

[0045] (4) In the step (3), the substrate is fermented and cultured in aerobic ventilation for 7 days at a temperature of 26° C. and a pH of 6.

[0046] (5) The product in the step (4) is thermally sterilized, kept at a temperature of 95° C. for 20 minutes, and spray-dried to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com