Zero-dimensional perovskite Cs4PbBr6 micro-crystal capable of regulating and controlling laser performance and preparation method thereof

A microcrystalline and perovskite technology, applied in chemical instruments and methods, lead compounds, inorganic chemistry, etc., can solve the problem of not having a good control method for laser performance, and achieve the effect of enhancing laser intensity and optimizing preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

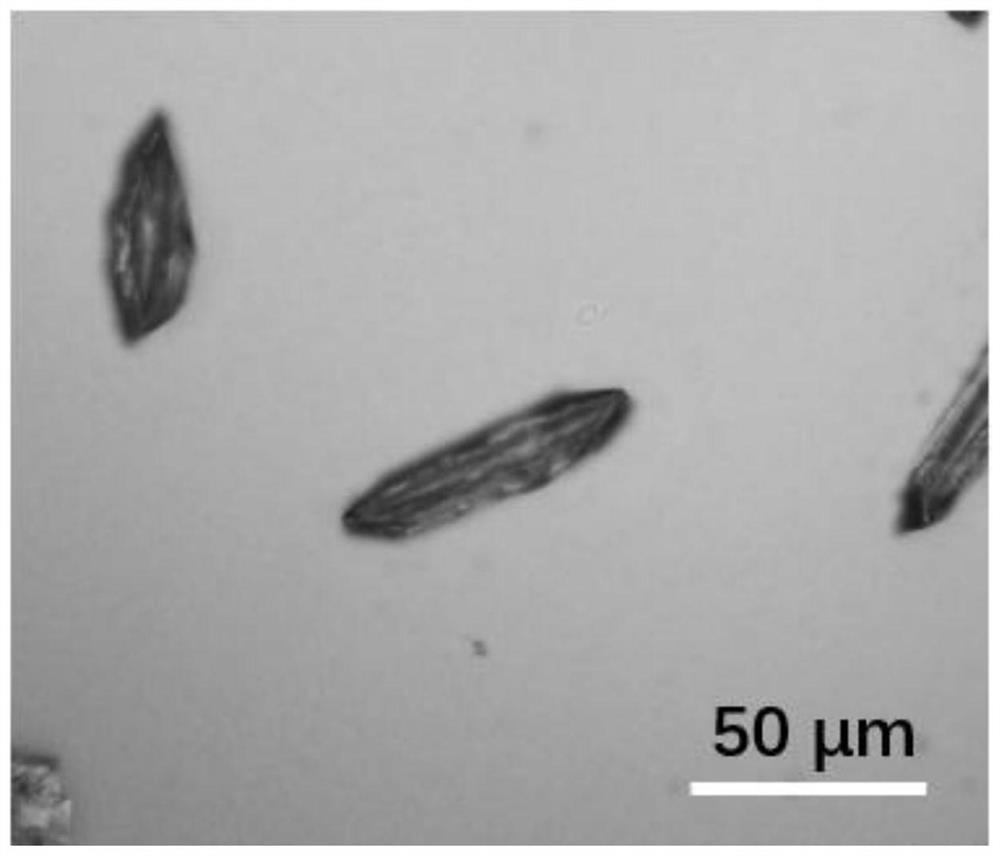

[0038] The zero-dimensional perovskite microcrystalline raw materials in this example are dissolved in dimethyl sulfoxide respectively, and a 0.2Mm CTAB-dimethyl sulfoxide solution precursor solution is prepared, and the raw materials cesium bromide and lead bromide are respectively dissolved in the precursor solution, and ensure that the molar concentration ratio cesium bromide: lead bromide: CTAB = 20:5:1, take an equal volume of cesium bromide, lead bromide dimethyl sulfoxide solution and mix it into a glass bottle. Open the glass bottle and put it into a larger airtight container and add dichloromethane into the container as an anti-solvent to ensure that the volume of dimethyl sulfoxide solution: dichloromethane volume = 1:5. React at 40°C for 48 hours , the microcrystalline powder of the product after washing and drying is the zero-dimensional perovskite Cs 4 PbBr 6 Microcrystalline. Microscopic topography such as figure 1 shown.

Embodiment 2

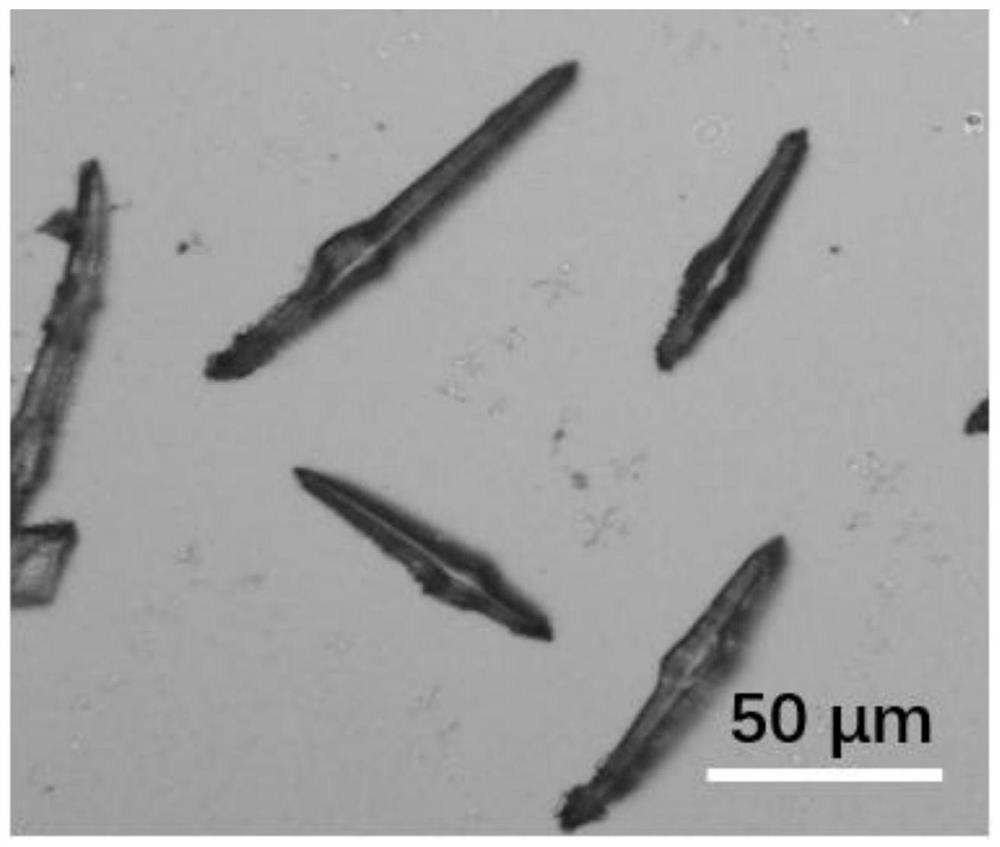

[0040] Configure the precursor solution of 0.2Mm CTAB-dimethyl sulfoxide solution, dissolve the raw materials cesium bromide and lead bromide in the precursor solution respectively, and ensure that the molar concentration ratio cesium bromide:lead bromide:CTAB=20:5 : 1. Take an equal volume of cesium bromide and lead bromide in dimethyl sulfoxide solution and mix them into a glass bottle. Open the glass bottle and put it into a larger airtight container and add dichloride to the container. Methane is used as an anti-solvent to ensure the volume of dimethyl sulfoxide solution: dichloromethane volume = 1:5. The reaction is carried out at 40°C for 72 hours, and the microcrystalline powder of the product after washing and drying is zero-dimensional perovskite Cs 4 PbBr 6 Microcrystalline. Microscopic topography such as figure 2 shown.

Embodiment 3

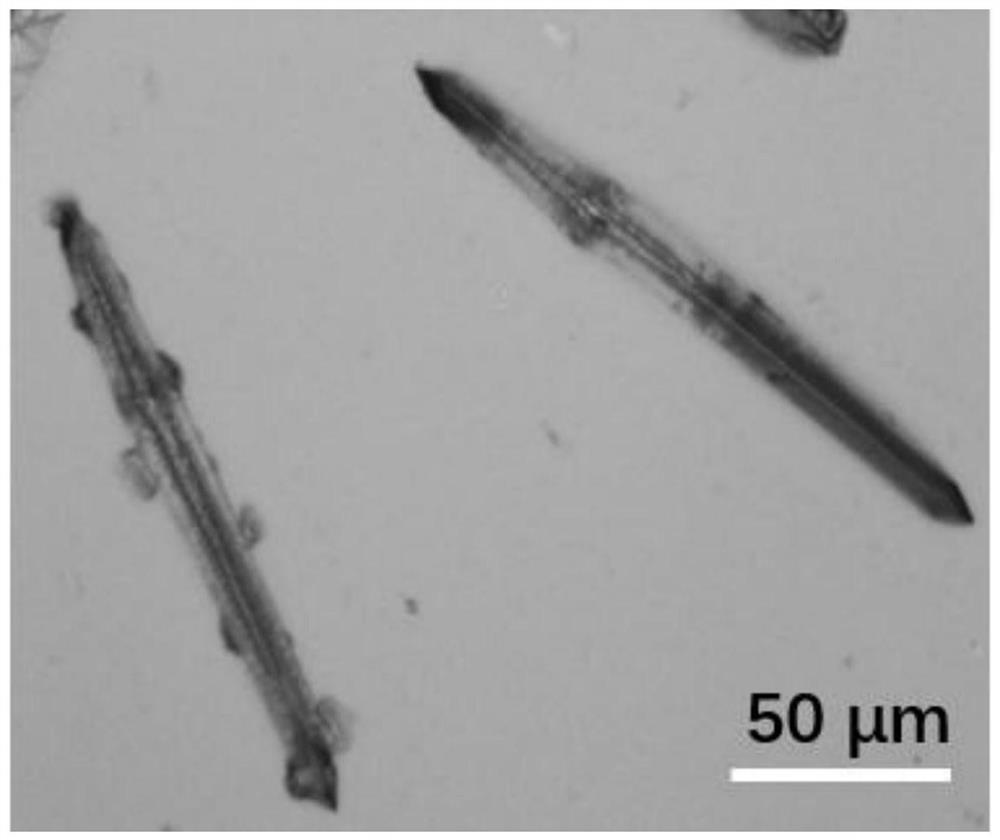

[0042] Configure the precursor solution of 0.2Mm CTAB-dimethyl sulfoxide solution, dissolve the raw materials cesium bromide and lead bromide in the precursor solution respectively, and ensure that the molar concentration ratio cesium bromide:lead bromide:CTAB=20:5 : 1. Take equal volumes of cesium bromide and dimethyl sulfoxide solution of lead bromide and mix them into a glass bottle, open the glass bottle and put it into a larger airtight container, and add two Chloromethane is used as an anti-solvent to ensure that the volume of dimethyl sulfoxide solution: dichloromethane volume = 1:5. The reaction is carried out at 40°C for 96 hours, and the microcrystalline powder of the product after washing and drying is zero-dimensional perovskite Cs 4 PbBr 6 Microcrystalline, microscopic morphology as shown in image 3 shown.

[0043] In this embodiment, the zero-dimensional perovskite Cs 4 PbBr 6 The relationship between laser intensity and threshold controlled by microcrystals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com