Refining method of bisphenol A epoxy resin

A refining method and epoxy resin technology, applied in the field of epoxy resin purification, can solve the problems of shortening the service life, difficult to remove co-catalysts, affecting the insulation performance of insulating parts, long-term stability of aging performance, etc., to achieve insulation performance and aging performance. Excellent, reduce the content of hydrolyzable chlorine, and ensure the effect of long-term safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The conventional process for the preparation of bisphenol A epoxy resin is to use bisphenol A and epichlorohydrin etherification reaction, and then undergo a ring-closing reaction to obtain the crude epoxy resin, and then refine the crude epoxy resin by a second ring-closing reaction. Finally, after purification, bisphenol A epoxy resin is obtained. Generally, when refining, since there is an organic phase in the crude epoxy resin, and there is an aqueous phase in sodium hydroxide, the refining reaction is only carried out at the interface between the aqueous phase and the organic phase. , the refining reaction is very limited, making hydrolyzable chlorine removal limited. Based on the original technology, the present invention adopts spraying and atomizing lye combined with multi-source and multi-frequency ultrasonic vibration, so as to remove the hydrolyzable chlorine in the epoxy resin to the greatest extent. It can be understood that the etherification reaction of b...

Embodiment 1

[0038] A refining method for bisphenol A type epoxy resin, comprising the following steps:

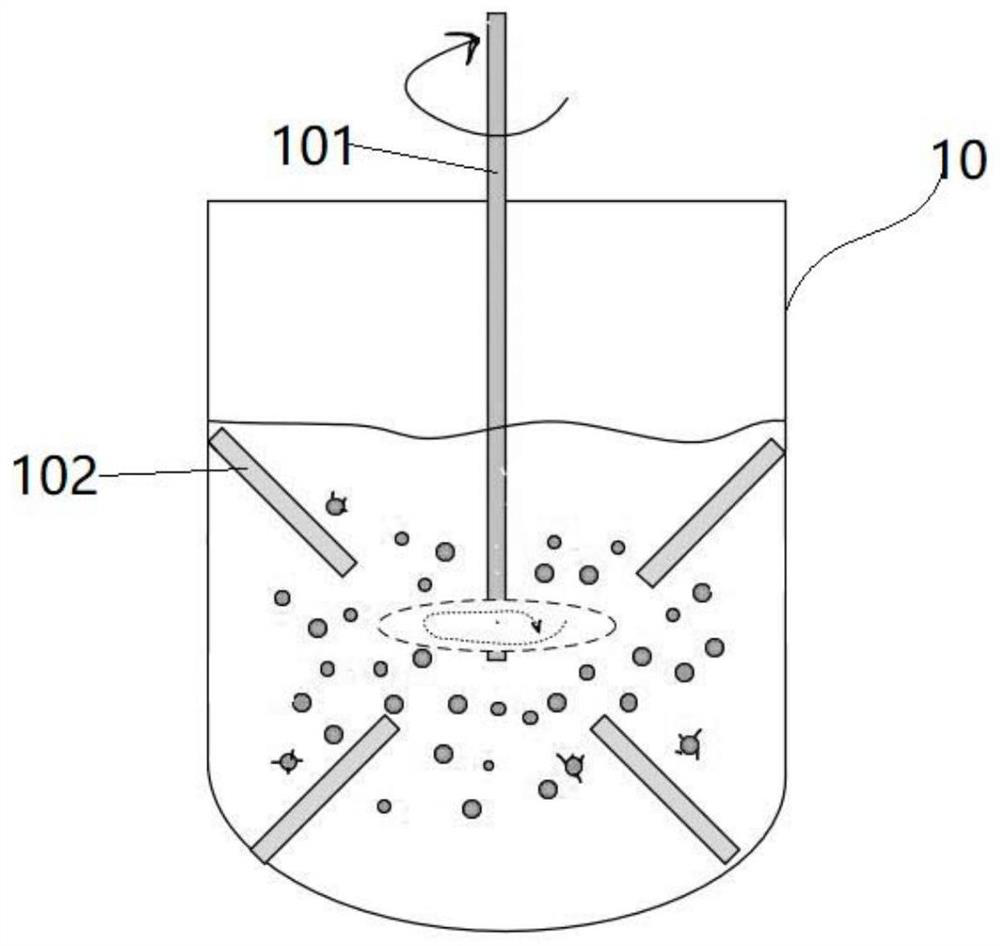

[0039] Add 224 g of crude epoxy resin, 260 mL of toluene and 50 mL of deionized water to figure 1 In the shown reactor 10;

[0040] 10.95g of NaOH solution with a mass fraction of 48.5% was added to the jet atomizer;

[0041]Turn on the jet atomizer (temperature range of high temperature tank: room temperature to 150°C, power supply: AC220V 50Hz) and turn on the reactor 10 to stir at the same time, spray and atomize the NaOH solution while stirring, and the stirring speed is 100rpm;

[0042] After the atomization of the NaOH solution is completed, adjust the temperature of the material in the reactor 10 to 75° C., and simultaneously set the stirring speed to 200 rpm;

[0043] Turn on the ultrasonic vibrating rod 102 (vibration frequencies are set to 27kHz, 35kHz, 25kHz and 40kHz in turn), perform multi-source multi-frequency ultrasonic vibration while stirring, and stop after 2 hours...

Embodiment 2

[0045] A kind of refining method of bisphenol A type epoxy resin, comprises the following steps:

[0046] Add 224 g of crude epoxy resin, 230 mL of toluene, and 38 mL of deionized water to figure 1 In the shown reactor 10;

[0047] Add 8.15g of NaOH solution with a mass fraction of 48.5% to the jet atomizer;

[0048] Turn on the jet atomizer (same as in Example 1) and simultaneously turn on the reactor 10 for stirring, and spray and atomize NaOH while stirring, and the stirring speed is 100rpm;

[0049] After the atomization of the NaOH solution is completed, adjust the temperature of the material in the reactor 10 to 85°C, and at the same time, set the stirring speed to 200rpm;

[0050] Turn on the ultrasonic vibrating rod 102 (same as in Example 1), perform multi-source multi-frequency ultrasonic vibration while stirring, and stop after reacting for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com