Resin composition, and prepreg, insulating film, metal foil-clad laminate and printed circuit board having same

A technology of resin composition and prepreg, which is applied in the direction of metal layered products, synthetic resin layered products, printed circuits, etc., can solve the problems affecting the water absorption rate of the final cured product, achieve excellent heat resistance, increase crosslinking density, The effect of excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

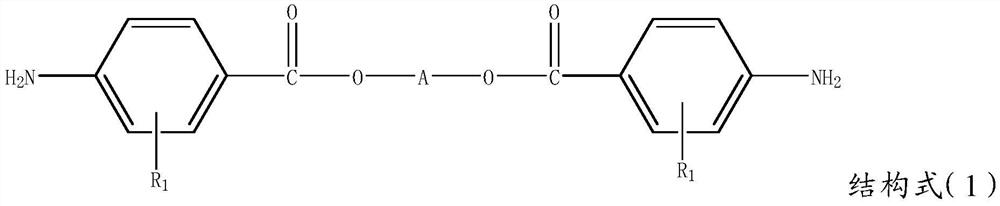

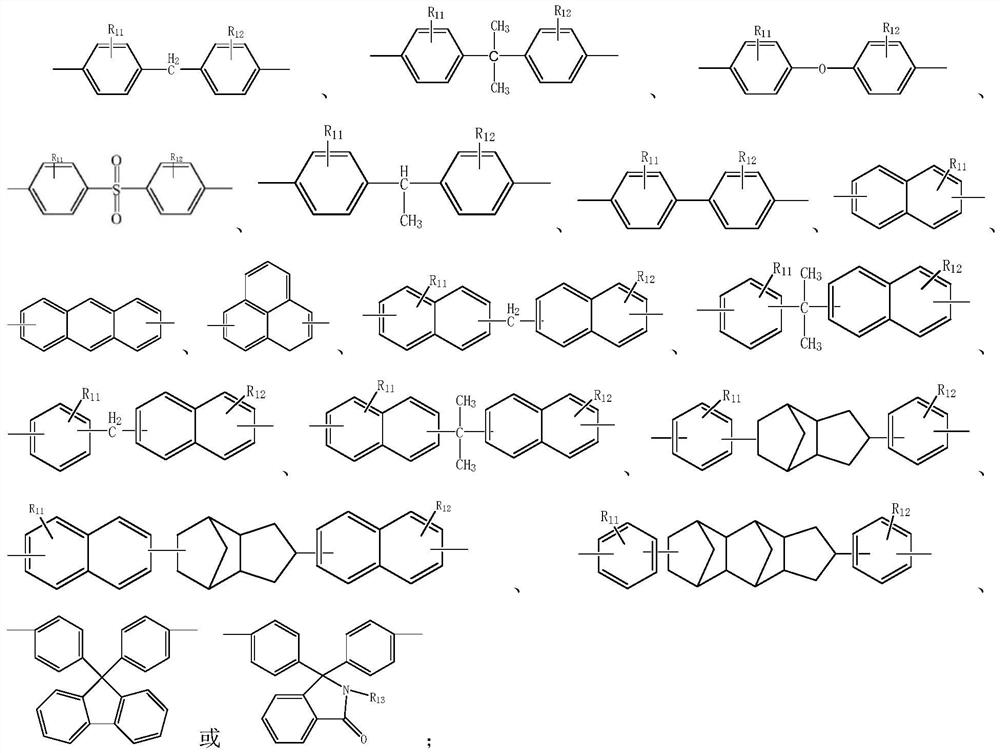

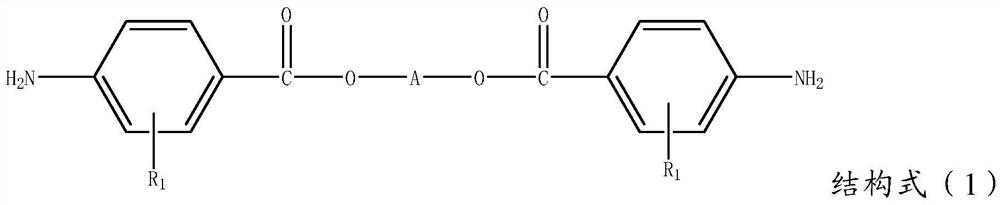

Method used

Image

Examples

Synthetic example 1

[0093] Synthesis Example 1: Synthesis of Dicyclopentadienyl Active Ester Compound

[0094] Get 1mol of dicyclopentadienyl phenol resin and 2mol of p-aminobenzoic acid (PABA), stir and dissolve in toluene solvent evenly, under the temperature condition of 60 ℃, feed nitrogen simultaneously, add tetrabutylammonium bromide catalyst, Then slowly drip a 20% sodium hydroxide aqueous solution, react for 4 hours, then finish the reaction and wash several times, and dry for 5 hours under vacuum conditions at 105°C to obtain the dicyclopentadienyl active ester Compound, denoted as active ester A.

Synthetic example 2

[0095] Synthesis Example 2: Synthesis of Tricyclopentadienyl Active Ester Compound

[0096] Take 1mol tricyclopentadienylphenol resin and 2mol p-aminobenzoic acid (PABA), stir and dissolve in toluene solvent evenly, and at a temperature of 60°C, feed nitrogen at the same time, add tetrabutylammonium bromide catalyst, Then slowly drip a 20% sodium hydroxide aqueous solution, react for 4 hours, and after the reaction is completed, after several washings, dry for 5 hours under vacuum conditions at 105°C to obtain the tricyclopentadienyl activity The ester compound is denoted as active ester B.

Synthetic example 3

[0097] Synthesis example 3: Synthesis of naphthyl active ester compound

[0098] Take 1 mol of naphthol resin and 2 mol of p-aminobenzoic acid (PABA), stir and dissolve in toluene solvent evenly, and at a temperature of 60°C, feed nitrogen at the same time, add tetrabutylammonium bromide catalyst, and then slowly drop into Concentration is 20% sodium hydroxide aqueous solution, react for 4 hours, then after several times of washing after reaction, under vacuum condition of 105 ℃, dry 5h, obtain described naphthyl active ester compound, denote as active ester C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com