Saturated steam process for biomass fuel processing

A biomass fuel and biomass raw material technology, applied in the field of saturated steam technology, can solve the problems of resource waste, poor energy saving and environmental protection effect, and increase processing cost and difficulty, so as to control processing cost, improve purity, and shorten processing chain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

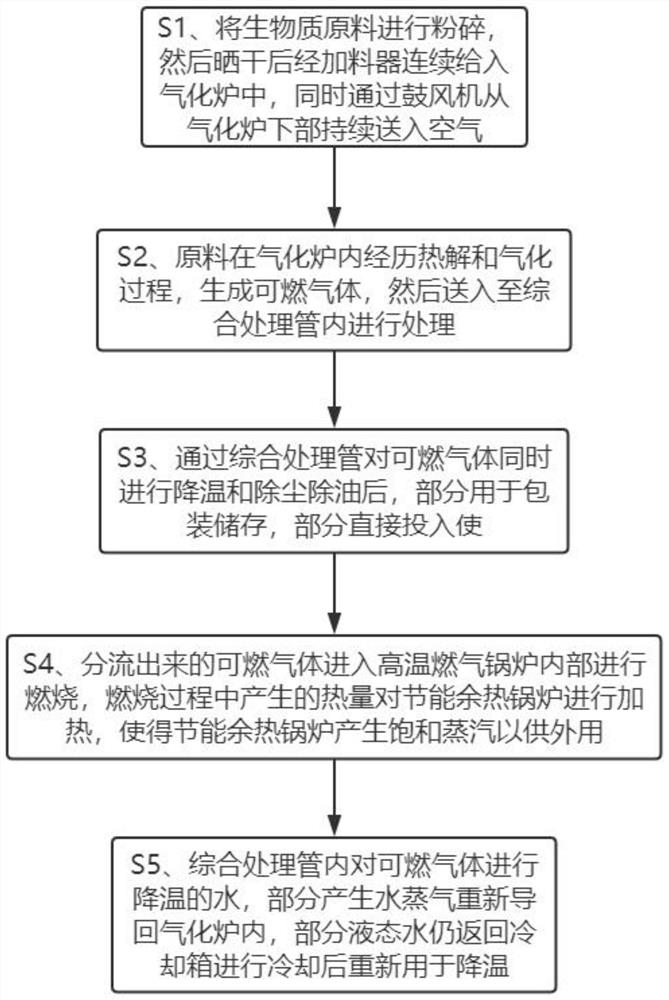

[0041] see Figure 1-2 , a saturated steam process for biomass fuel processing, comprising the following steps:

[0042] S1. The biomass raw material is crushed, then dried and fed continuously into the gasification furnace through a feeder, and at the same time, air is continuously fed from the lower part of the gasification furnace through a blower;

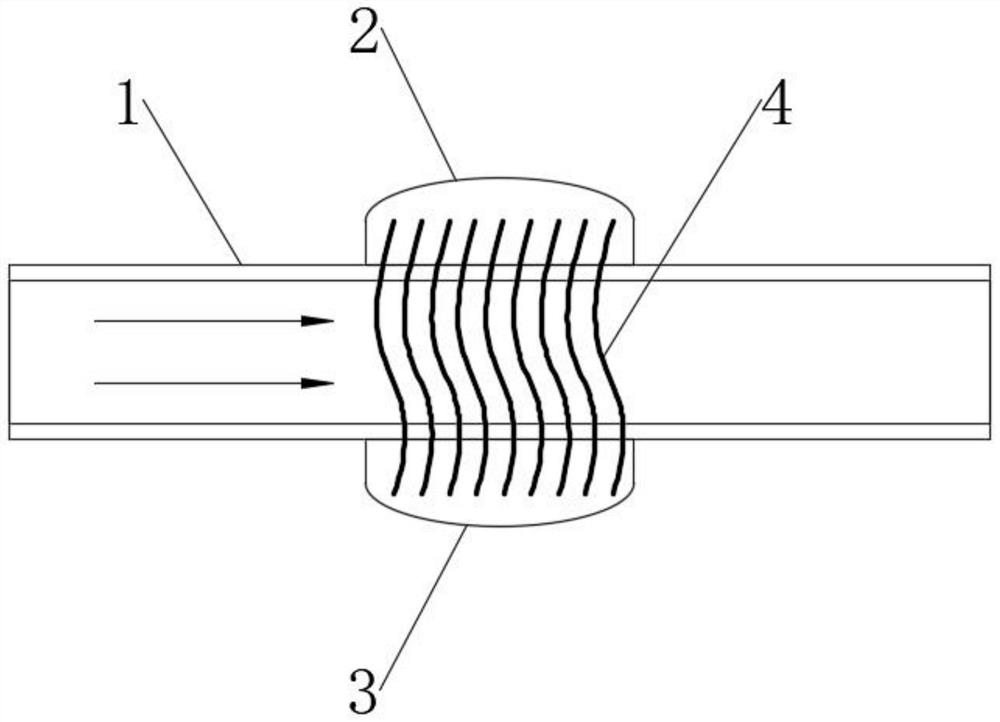

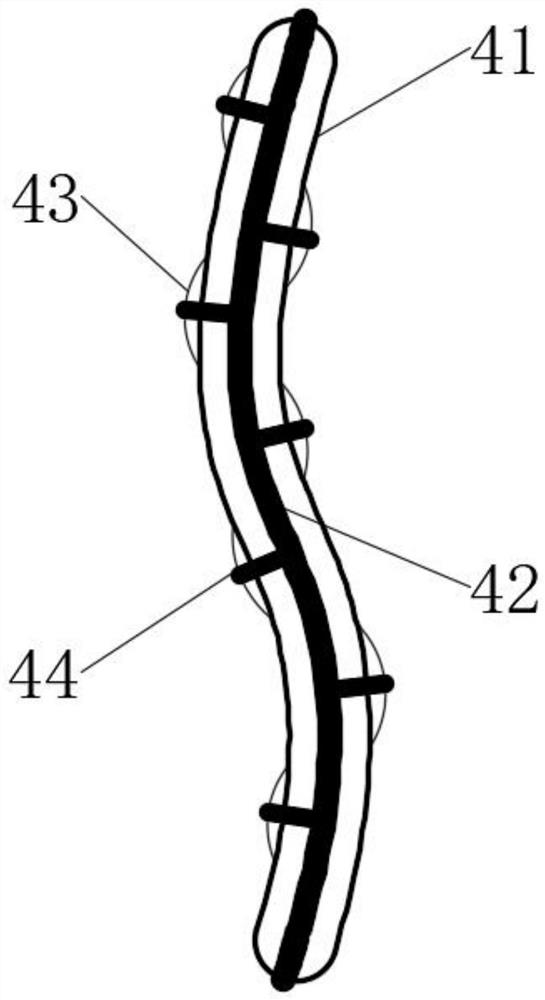

[0043] S2. The raw material undergoes pyrolysis and gasification process in the gasifier to generate combustible gas, which is then sent to the comprehensive processing pipe 1 for processing;

[0044] S3. After the combustible gas is cooled and dust-removed and oil-removed at the same time through the comprehensive treatment pipe 1, part of it is used for packaging and storage, and part of it is directly put into use;

[0045] S4. The diverted combustible gas enters the high-temperature gas-fired boiler for combustion, and the heat generated during the combustion process heats the energy-saving waste heat boiler, so that the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com