Dynamic brewing method of low-alcohol fruit wine

A mellow fruit wine and dynamic technology, applied in the field of food and beverage, can solve the problems of sugar-acid balance breakdown, damage to sensory experience, consumption, etc., to achieve the effect of ensuring health and safety, good sensory experience, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Alcohol-producing ability test of strain

[0026] TTC plate: 0.5g / L TTC, 5g / L glucose, 15g / L agar.

[0027] YPD plate: 10g / L yeast extract powder, 20g / L yeast peptone, 20g / L glucose, 20g / L agar.

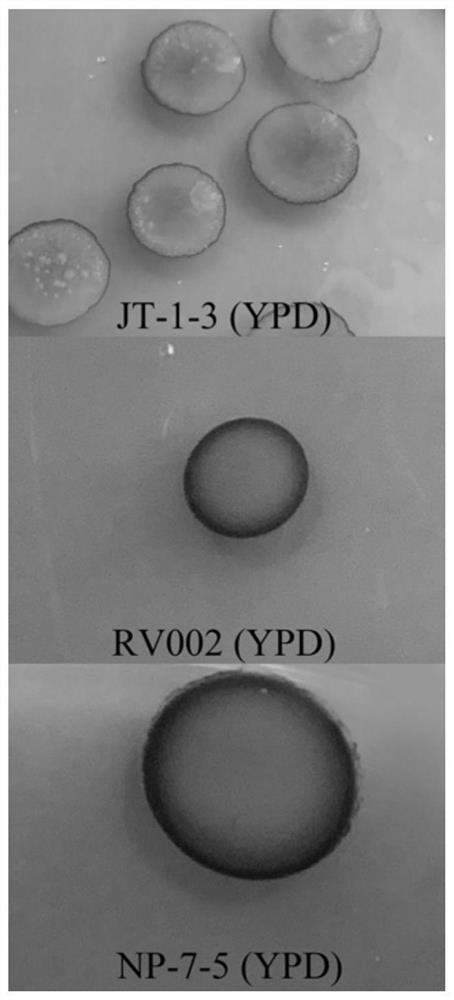

[0028] The applicant used a strain of Pichia pastoris JT-1-3 obtained by the preliminary screening (this strain has been disclosed in the patent document of CN 108676736 A), as well as two other strains of common Saccharomyces cerevisiae RV002 and NP-7-5 in the laboratory. experimenting.

[0029] Spread JT-1-3, RV002 and NP-7-5 on YPD plates and incubate them at 28°C for 60 hours, then cover the TTC plates incubated at 50°C on the YPD plates and incubate at 28°C in the dark for 3 hours. Take pictures and record the results. The colorless TTC can be reduced to red TTF during the yeast production process. The darker the color, the stronger the yeast production capacity. The result is as follows figure 2 As shown in the figure, it can be seen that JT-1-3 shows weaker alcohol...

Embodiment 2

[0030] Example 2 Fermentation ability test of strain

[0031] VHG medium: 200g / L glucose, 8g / L yeast peptone, 10g / L yeast extract powder.

[0032] In this experiment, JT-1-3, RV002 and NP-7-5 were inoculated in a VHG medium slightly higher than the sugar concentration in the juice, and their fermentation ability was tested to determine their potential in fruit wine fermentation. JT-1-3, RV002 and NP-7-5 were inoculated into VHG medium at an inoculum of 3% (v / v), cultured at 28°C, 120r / min, and weighed every 12h Stop the experiment until its quality no longer drops. The results show that the fermentation speed of JT-1-3 is slightly weaker than that of ordinary Saccharomyces cerevisiae, but it can also enter the stable fermentation period at 72h, and the fermentation weight loss of JT-1-3 is slightly greater than that of Saccharomyces cerevisiae in the late fermentation period.

Embodiment 3

[0033] Example 3: Fermentation experiment of kiwi fruit wine

[0034] The following takes kiwi fruit wine as an example to further describe the dynamic brewing method of the present invention in detail.

[0035] 1) Wash the fresh kiwi fruit and peel it, squeeze the juice and add 0.2% pectinase to enzymatically treat it for 3 hours, then filter the juice and paste it for use;

[0036] 2) Activate the non-Saccharomyces cerevisiae-Pichia pastoris JT-1-3 to a bacterial content of 10 7 -10 8 CFU / mL, collect the yeast cells after centrifugation and wash them with sterile saline until there is no peculiar smell, then adjust the concentration of the bacterial solution to 10 with sterile water 10 -10 12 CFU / mL;

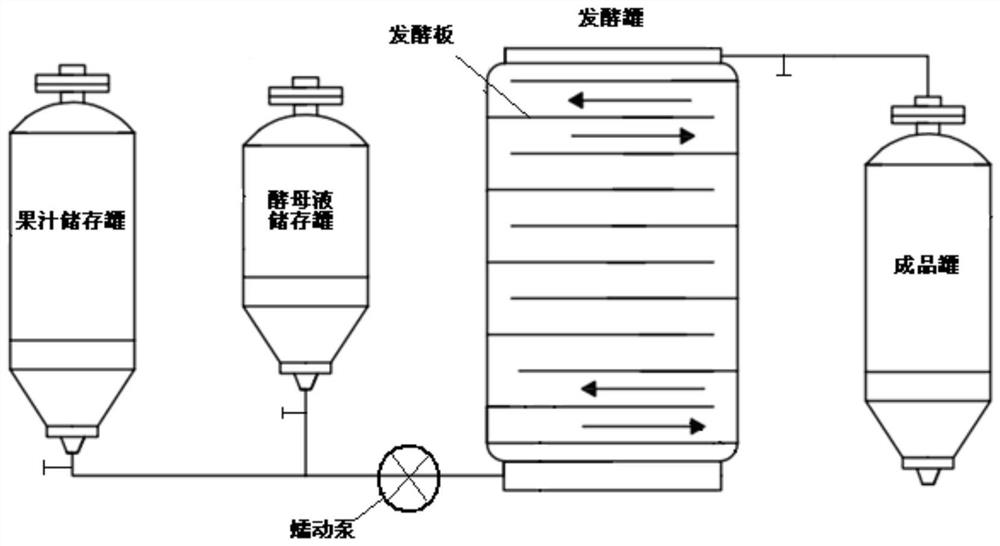

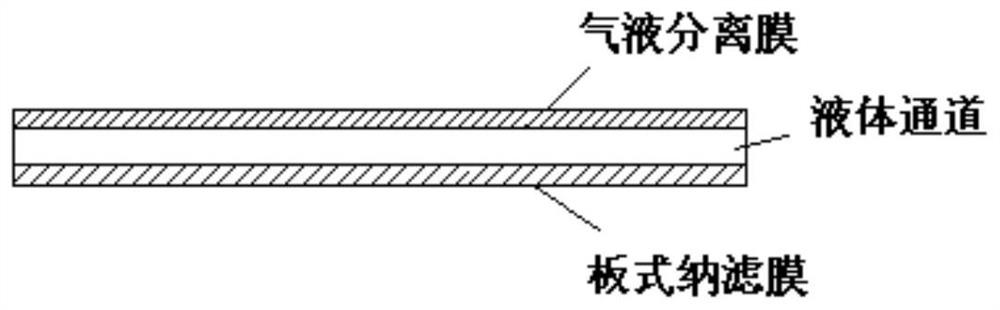

[0037] 3) Pass the adjusted concentration of yeast liquid into the fermentation tank (structure such as figure 1 (Shown), the fermentation tank is provided with several layers of fermentation plates staggered up and down, and the fermentation plate is composed of a plate ultrafiltratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap