Cellulose-based multifunctional absorbing material and preparation and application methods thereof

A cellulose-based, adsorption material technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as the difficulty of compounding hydrophobic materials, and achieve excellent adsorption capacity, excellent mechanical properties, and good mechanical properties. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

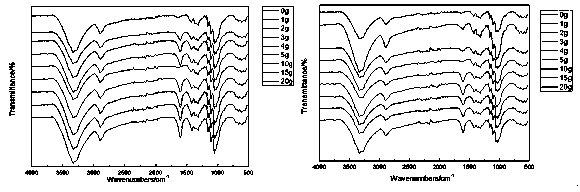

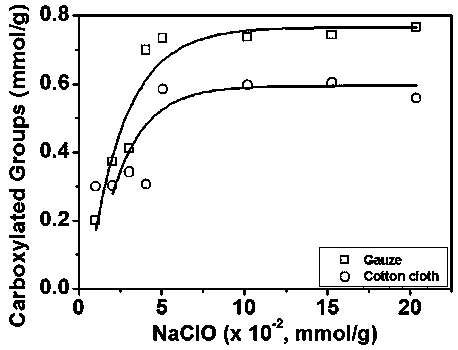

[0032] Example 1: Preparation of cellulose-based multifunctional absorbent cloth: A certain amount of gauze (or cotton cloth) is placed in water dissolved with an appropriate amount of TEMPO and NaBr, and a predetermined amount of NaClO solution is added to keep the pH of the system at about 11. After reacting for a certain period of time, add ethanol to terminate the reaction, filter, wash with deionized water until neutral, and dry. Put the product in a certain amount of NaIO 4In aqueous solution, room temperature or heating reaction for 12 to 48 hours. The product was filtered, washed, and dried to obtain a cellulose-based multifunctional adsorption cloth oxidized by TEMPO / NaIO4.

example 2

[0033] Example two: reverse the oxidation process in example one, that is, carry out NaIO first 4 oxidation, followed by a brief TEMPO oxidation process to give NaIO 4 / TEMPO oxidized cellulose-based multifunctional absorbent cloth, both of which have different surface carboxyl and aldehyde content.

example 3

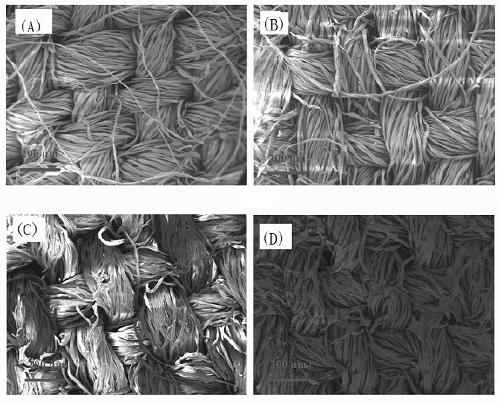

[0034] Example 3: Will go through TEMPO, NaIO 4 The oxidized cloth is observed with SEM, see as figure 1 The fiber morphology shown. It can be seen that by adjusting the degree of oxidation, the cotton cloth or gauze can keep the original shape basically unchanged, that is, maintain the original mechanical strength, but introduce functional groups such as carboxyl and aldehyde groups on the surface. from figure 1 It can also be seen that the first NaIO 4 The surface morphology of the cellulose adsorption cloth obtained by oxidation and then TEMPO oxidation changed greatly, which meant a higher degree of surface functionalization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com