Solid-phase micro-extraction analysis method

A technology of solid-phase microextraction head and analysis method, applied in the field of solid-phase microextraction analysis, can solve the problems of reduced extraction efficiency, high incubation extraction temperature, unstable analyte, etc., and achieves simple and easy operation and easy online monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take 0.2g of shredded tobacco into two 20ml headspace injection bottles respectively, and pump one of the headspace injection bottles with a 25ml syringe with an injection needle for several times until the pumping piston stops when it is difficult to pull. Coat the headspace bottle cushion with vacuum grease to serve as the experimental group; the control sample was not subjected to the above treatment, and the headspace sample bottle was placed in a heating furnace and heated to 250 ° C for 3 minutes. The experimental group bottle cap was intact, and the headspace of the control sample was intact. The soft cap of the vial cap burst and popped out.

Embodiment 2

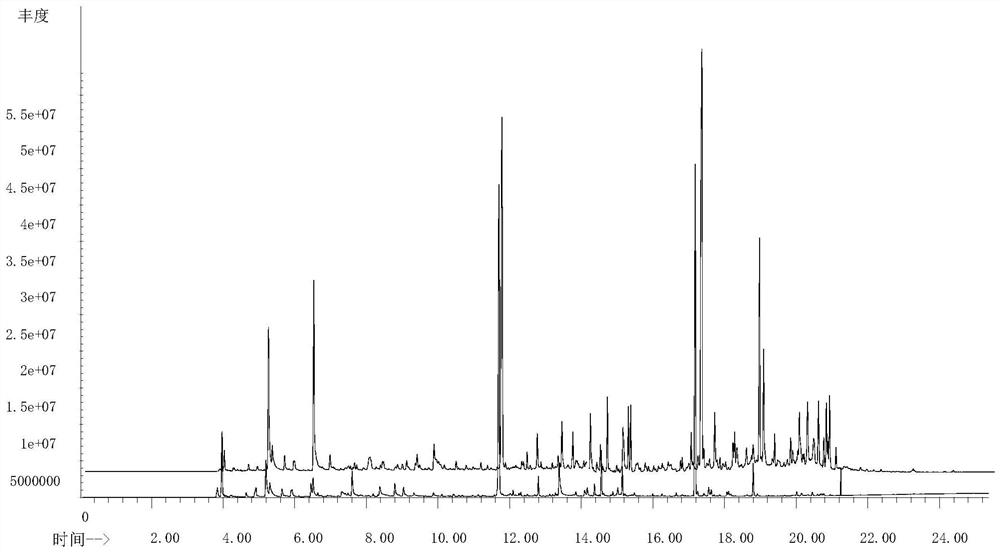

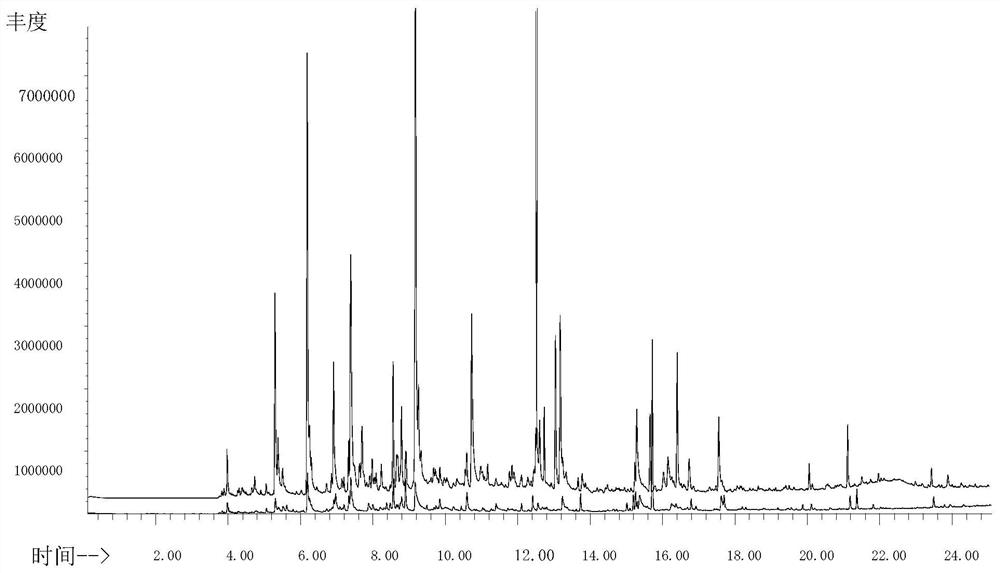

[0042]Take 0.2g of shredded tobacco into two 20ml headspace sampling bottles respectively, connect one of the headspace sampling bottles to a circulating vacuum pump with a syringe with an injection needle and pump for a few minutes. After the pressure gauge of the vacuum pump is stable at 0.1mp, Put the sample into a heating furnace and heat it to 250 °C, keep it for 3 minutes, take out the headspace sampling bottle, and take it as the experimental group; Headspace solid-phase microextraction time was 50 min. Take out the solid-phase microextraction needle, and then perform analytical injection at the injection port of the gas chromatography-mass spectrometer. Compared with the control group, the information on the volatile components of the cut tobacco treated with negative pressure and high temperature is obviously rich, especially the types and contents of high-boiling components are significantly increased (see figure 1 , in general, the higher the boiling point, the lat...

Embodiment 3

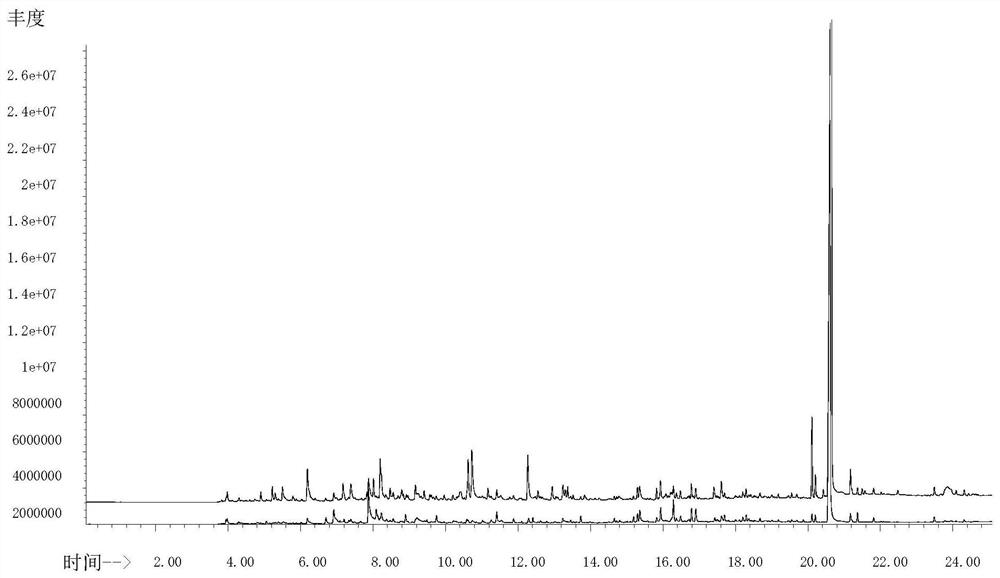

[0044] Take 0.5g of dry soybean powder into two 20ml headspace injection vials, connect one of the headspace injection vials to a circulating vacuum pump with a syringe with an injection needle and pump for a few minutes. The pressure gauge of the vacuum pump is stable at 0.1mp. After that, put the sample into a heating furnace and heat it to 250 °C, keep it for 3 minutes, take out the headspace sampling bottle, and take it as the experimental group; 5min, headspace solid-phase microextraction time 30min. Take out the solid-phase microextraction needle, and then perform analytical injection at the injection port of the gas chromatography-mass spectrometer. Compared with the control group, the relative abundances of volatile components of soybean flour treated with negative pressure and high temperature were significantly enhanced, and the component information was significantly enriched.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com