Self-powered airflow sensor and production method thereof

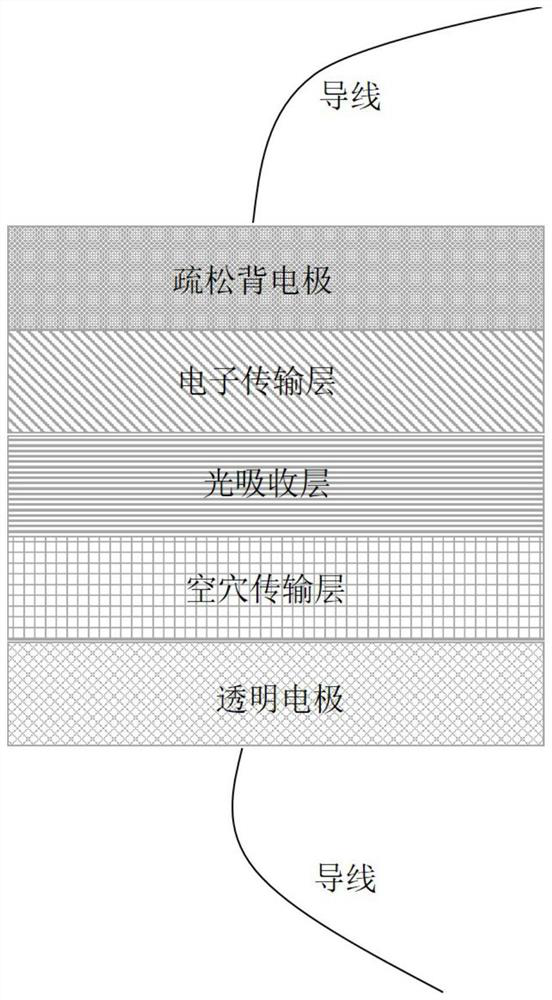

An airflow sensor and self-powered technology, applied in the field of airflow sensors, can solve the problems of small device size, low sensitivity, and high manpower and material resources, and achieve the effect of easy integration and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Place the ITO glass in ethanol, acetone, and isopropanol for ultrasonic cleaning for 15 minutes, and then dry it with a nitrogen gun. Spin-coat PEDOT:PSS on ITO at a speed of 3000r / min for 30s, and then heat on a hot stage at 120°C for 10min, thus completing the preparation of the hole transport layer;

[0039] 2. Combine MaI and PbI 2 Dissolved in DMF:DMSO (volume ratio 4:1), stirred at 70°C for 30min to obtain 1.4mol / L perovskite MaPbI 3 Solution, spin-coat the perovskite solution on the hole transport layer. The process is to spin-coat at 1000r / min for 5s, then spin-coat at 4000r / min for 30s. In the second stage of 7s, add 350μL of toluene as anti-solvent, and then Annealing, first annealing at 60°C for 1min, then annealing at 80°C for 5min;

[0040] 3. The electron transport material PCBM was dissolved in chlorobenzene to prepare a 20mg / mL solution, and the PCBM solution was spin-coated on the perovskite layer at 600r / min for 2min. Afterwards, place the sheet ...

Embodiment 2

[0047] The structure and preparation method of the airflow sensor in this embodiment are the same as in Embodiment 1, the only difference is that the back electrode is replaced by carbon paste with silver paste, which is still prepared by screen printing process, and the obtained sensor is recorded as ITO / PEDOT:PSS / PVK / PCBM / Ag.

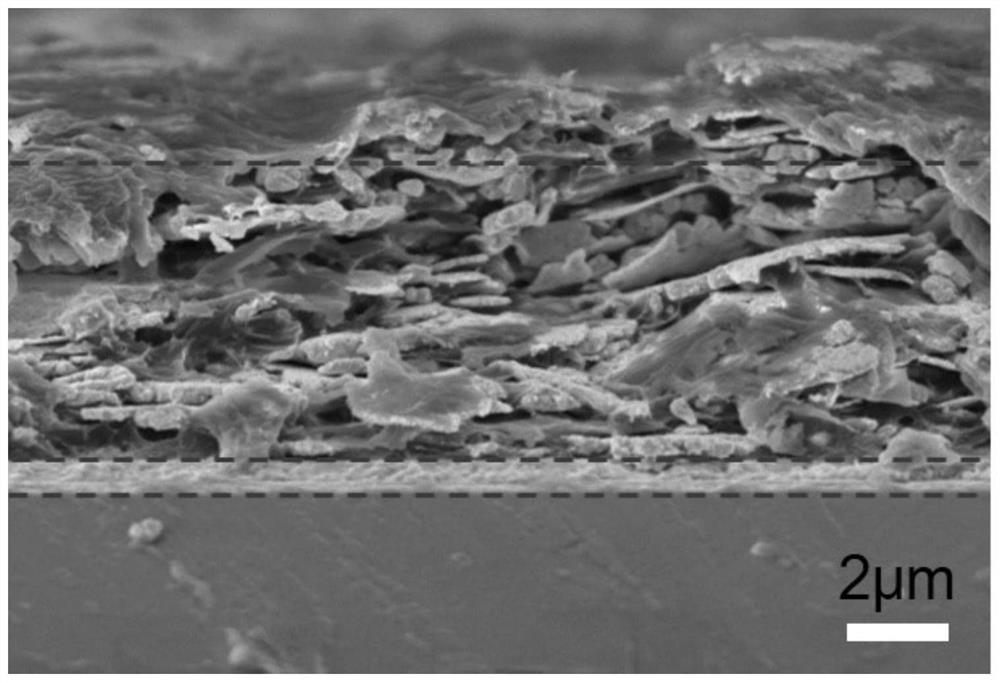

[0048] Figure 4 It is the cross-sectional electron microscope image of the sensor prepared in Example 2. It can be seen that the silver electrode prepared by the screen printing process presents a loose and porous structure, and the thickness of the back electrode is about 10 μm, which is much thicker than that prepared by the spin coating method below. The sum of the thicknesses of the electron transport layer, light absorbing layer and hole transport layer.

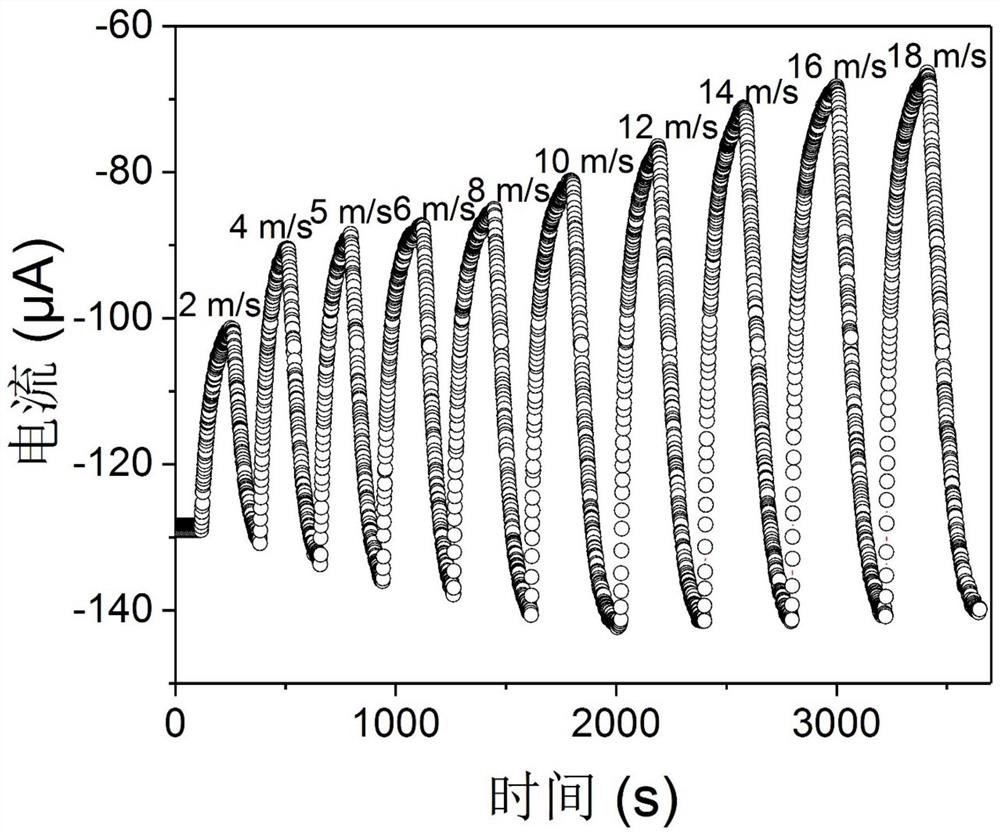

[0049] Figure 5When the ITO / PEDOT:PSS / PVK / PCBM / Ag sensor prepared in Example 2 is exposed to different flow rates, the current between the two electrodes varies with time. It can be seen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com