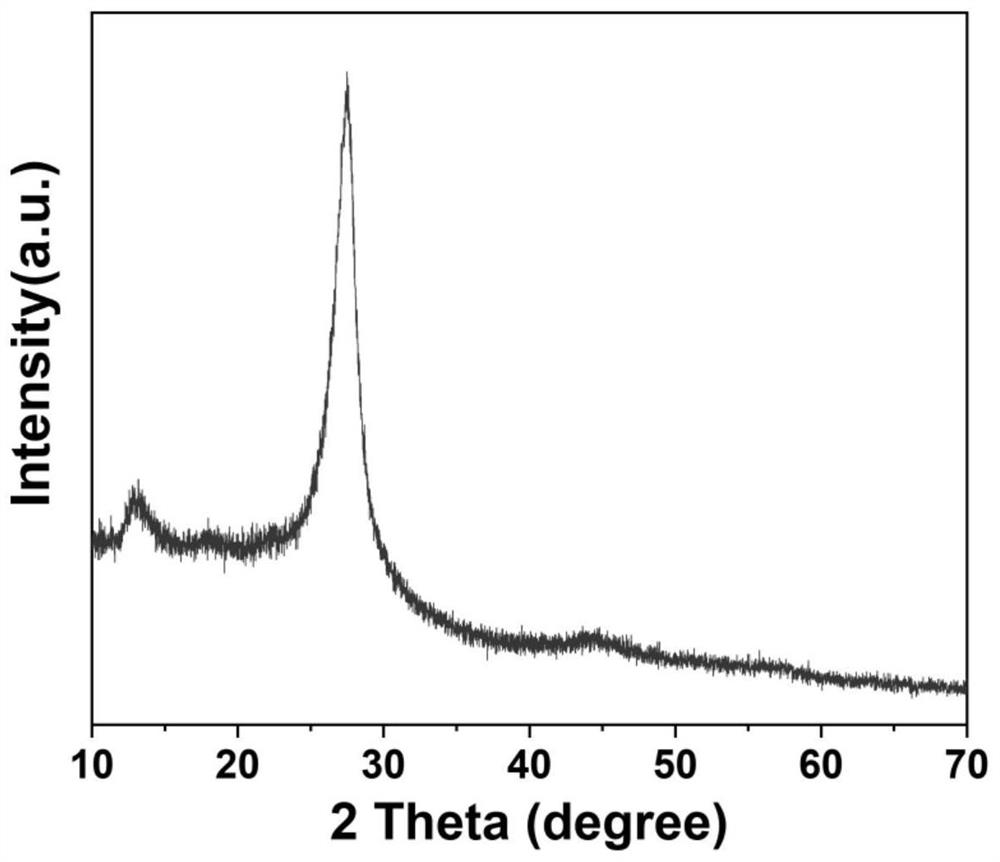

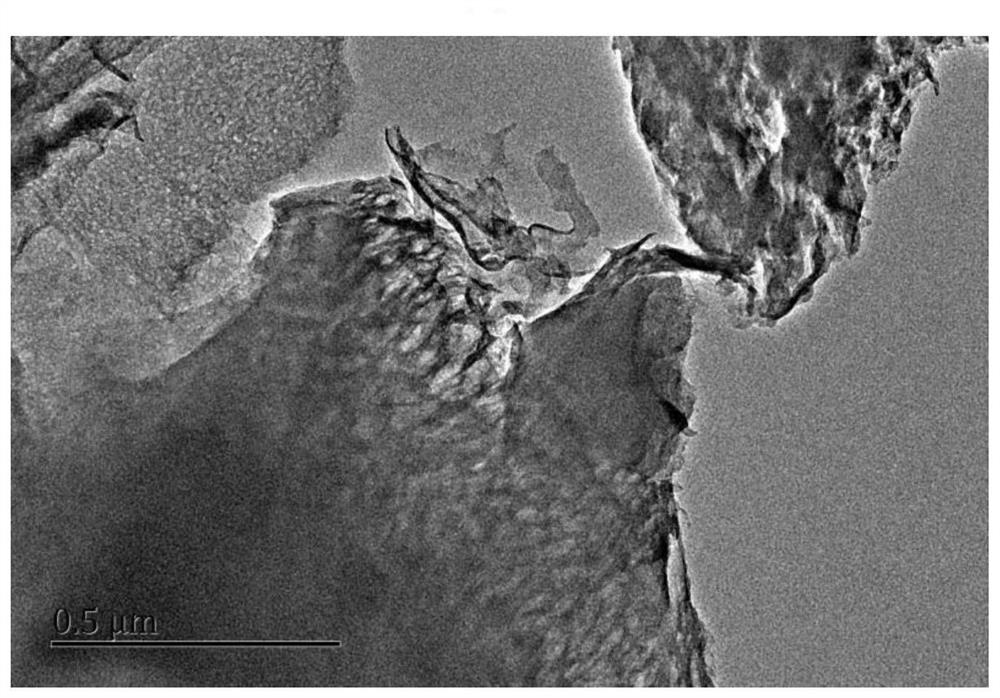

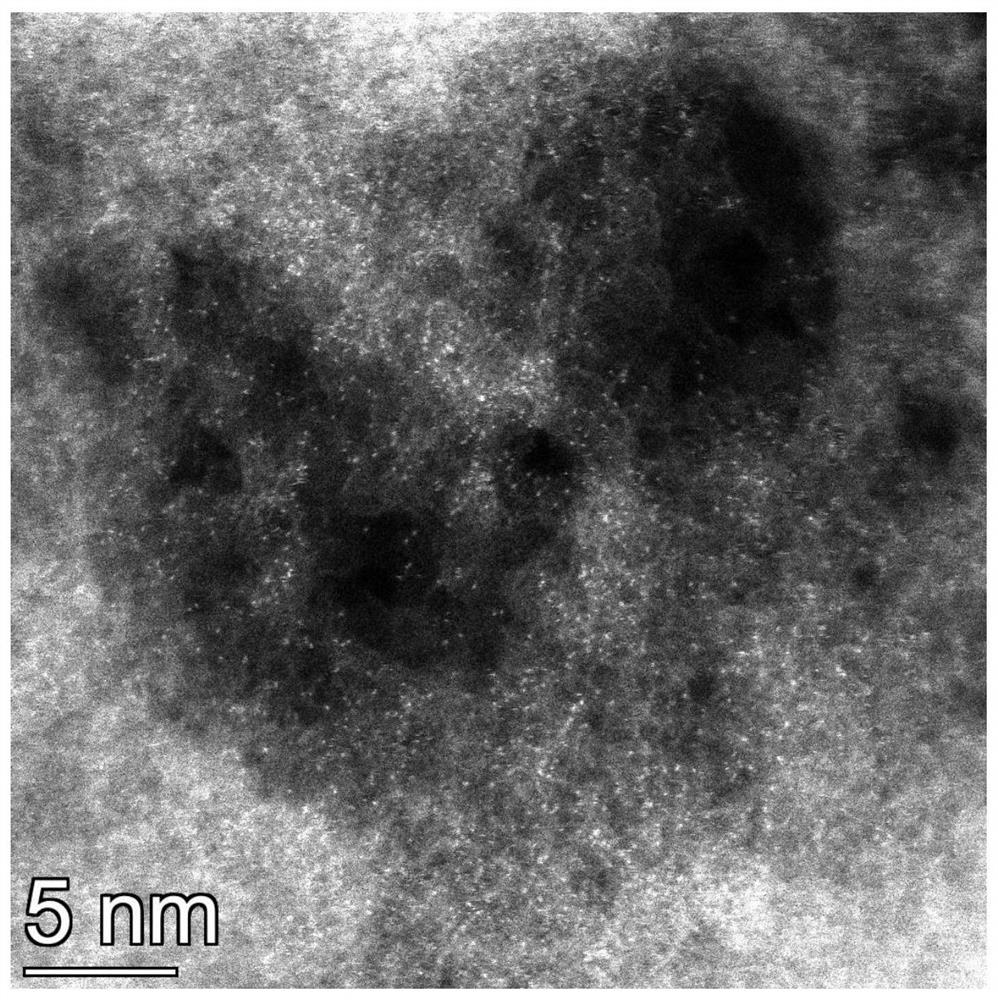

Monatomic copper catalyst as well as gram-level preparation method and application thereof to selective reduction of functional organic molecules

A copper catalyst and atomic technology, which is applied in the field of synthesis of non-noble metal single-atom materials, can solve the problems of low utilization rate of catalytic active sites, difficulty in multiple recycling, low hydrogenation selectivity, etc., and achieve simple operation, low raw material cost, The effect of high experimental repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Place 10g of melamine in a two-necked flask, add anhydrous methanol, ultrasonically disperse for 10min, add 3mL of glyoxal aqueous solution and ultrasonically disperse for 30min, place the two-necked flask on a magnetic heating stirrer, and connect the mouth of the two-necked flask The condenser tube, the other end of the condenser tube is plugged with a rubber stopper, and it is condensed and refluxed in an oil bath at 70°C for 2 hours to obtain process product A; process product A is centrifuged and dried to obtain product B; among which process product A is separated The centrifugation speed is 4000r / min, and the centrifugation time is 2 times, each centrifugation time is 7min; the centrifugal product A is dried at 60°C for 24h to remove the reaction solvent methanol; the volume ratio of the mass of melamine to anhydrous methanol is 1g:5mL; The concentration of the glyoxal aqueous solution is 8.8 mol / L; the molar ratio of glyoxal to melamine in the glyoxal aqueous s...

Embodiment 2

[0046] 1) Place 10g of melamine in a two-necked flask, add anhydrous methanol, ultrasonically disperse for 10min, add 3mL of glyoxal aqueous solution and ultrasonically disperse for 30min, place the two-necked flask on a magnetic heating stirrer, and connect the mouth of the two-necked flask The condenser tube, the other end of the condenser tube is plugged with a rubber stopper, and it is condensed and refluxed in an oil bath at 70°C for 2 hours to obtain process product A; process product A is centrifuged and dried to obtain product B; among which process product A is separated The centrifugal speed is 4000r / min, the centrifugation is 4 times, and the time of each centrifugation is 4min; the centrifugal product A is dried at 60°C for 24h to remove the reaction solvent methanol; the volume ratio of the mass of the melamine to the anhydrous methanol is 1g:5mL; The concentration of the glyoxal aqueous solution is 8.8 mol / L; the molar ratio of glyoxal to melamine in the glyoxal aq...

Embodiment 3

[0051] 1) Place 10g of melamine in a two-necked flask, add anhydrous methanol, ultrasonically disperse for 10min, add 3mL of glyoxal aqueous solution and ultrasonically disperse for 30min, place the two-necked flask on a magnetic heating stirrer, and connect the mouth of the two-necked flask The condenser tube, the other end of the condenser tube is plugged with a rubber stopper, and it is condensed and refluxed in an oil bath at 70°C for 2 hours to obtain process product A; process product A is centrifuged and dried to obtain product B; among which process product A is separated The centrifugal speed is 4000r / min, the centrifugation is 3 times, and the centrifugation time is 5min each time; the centrifugal product A is dried at 60°C for 24h to remove the reaction solvent methanol; the volume ratio of the mass of melamine to the anhydrous methanol is 1g:5mL; The concentration of the glyoxal aqueous solution is 8.8 mol / L; the molar ratio of glyoxal to melamine in the glyoxal aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com