Cadmium sulfide/nickel tungstate composite visible light catalyst, preparation method and application

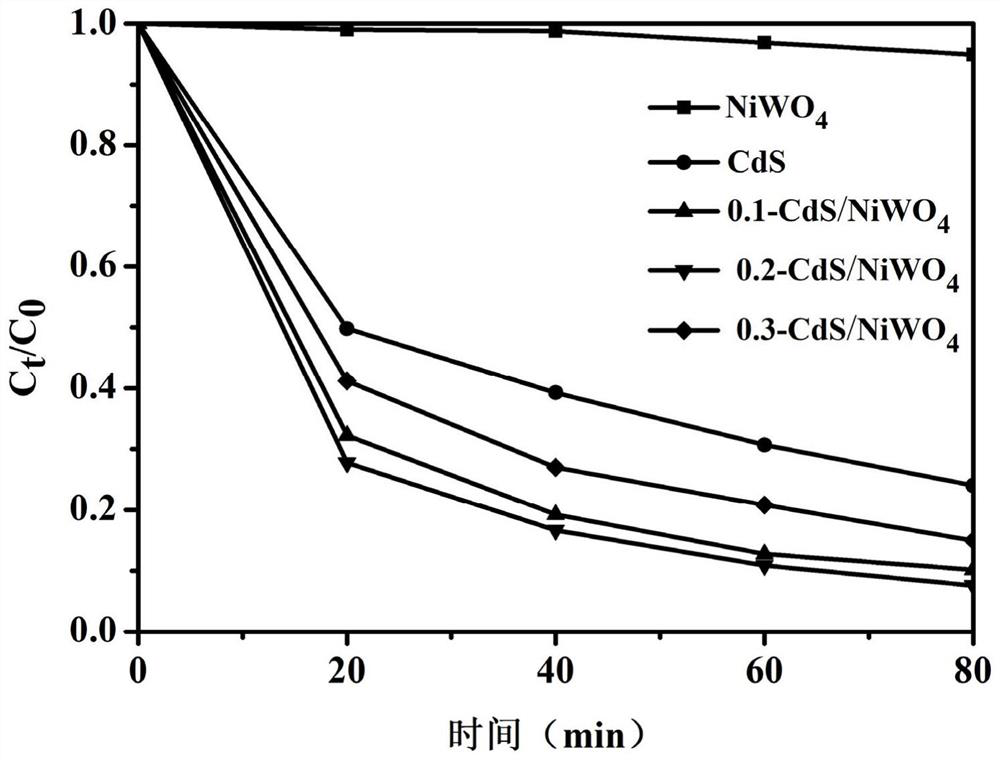

A technology of nickel tungstate and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low photocatalytic activity and high electron-hole recombination rate of pure nickel tungstate , to achieve the effects of excellent photocatalytic activity, good stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

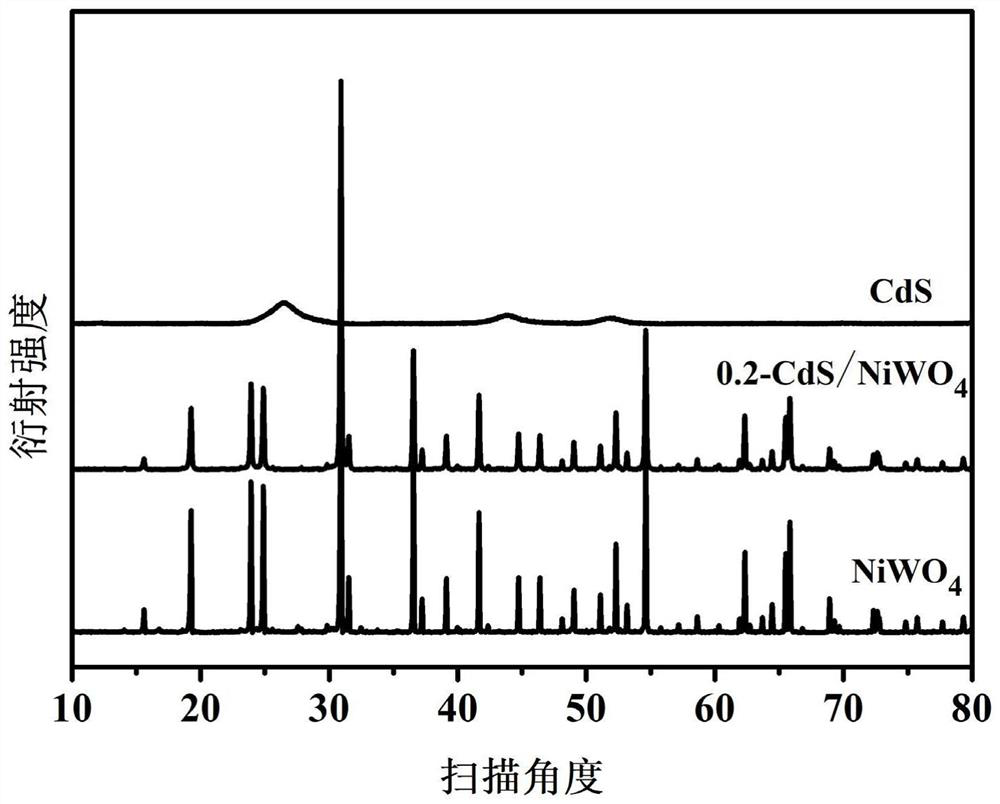

[0025] (1) Preparation of nickel tungstate: add 0.33g of nickel nitrate and 0.291g of sodium tungstate into 30ml of deionized water respectively, and stir magnetically for 2 hours to obtain a homogeneous solution. Then the sodium tungstate solution was added dropwise to the nickel nitrate solution, and the stirring was continued for 2 hours. Then, the obtained mixed solution was transferred to a 100ml reactor, and reacted hydrothermally at 180°C for 16 hours. The obtained product was centrifuged and washed 3 times with deionized water and ethanol, and dried at 100°C for 2 hours, and finally the dried powder was calcined in a muffle furnace at 700°C for 4 hours to obtain a light yellow powdery nickel tungstate sample .

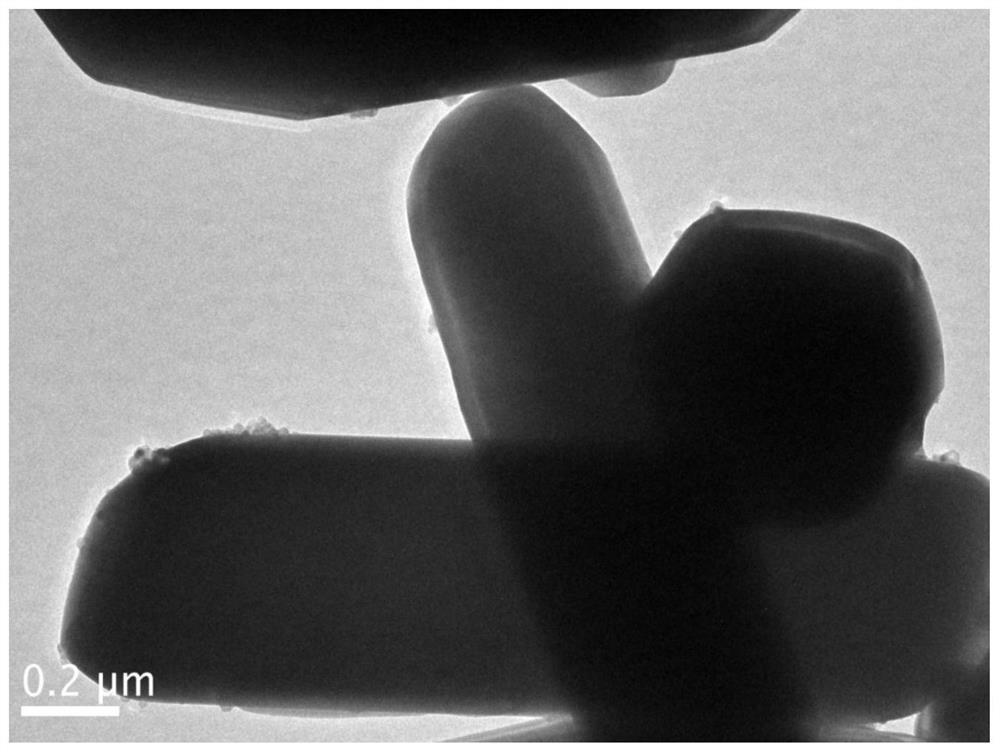

[0026] (2) Preparation of cadmium sulfide / nickel tungstate composite photocatalyst: Weigh 0.1g nickel tungstate and add it to 70ml ethylene glycol, stir magnetically for 1h, then add 0.018432g cadmium acetate, continue ultrasonication for 1h, then add 0.0052g s...

Embodiment 2

[0028] (1) Preparation of nickel tungstate: add 0.33g of nickel nitrate and 0.291g of sodium tungstate into 30ml of deionized water respectively, and stir magnetically for 2 hours to obtain a homogeneous solution. Then the sodium tungstate solution was added dropwise to the nickel nitrate solution, and the stirring was continued for 2 hours. Then, the obtained mixed solution was transferred to a 100ml reactor, and reacted hydrothermally at 180°C for 16 hours. The obtained product was centrifuged and washed 3 times with deionized water and ethanol, and dried at 100°C for 2 hours, and finally the dried powder was calcined in a muffle furnace at 700°C for 4 hours to obtain a light yellow powdery nickel tungstate sample .

[0029] (2) Preparation of cadmium sulfide / nickel tungstate composite photocatalyst: Weigh 0.1g nickel tungstate and add it to 70ml ethylene glycol, stir magnetically for 1h, then add 0.036864g cadmium acetate, continue ultrasonication for 1h, then add 0.0104g s...

Embodiment 3

[0031] (1) Preparation of nickel tungstate: add 0.33g of nickel nitrate and 0.291g of sodium tungstate into 30ml of deionized water respectively, and stir magnetically for 2 hours to obtain a homogeneous solution. Then the sodium tungstate solution was added dropwise to the nickel nitrate solution, and the stirring was continued for 2 hours. Then, the obtained mixed solution was transferred to a 100ml reactor, and reacted hydrothermally at 180°C for 16 hours. The obtained product was centrifuged and washed 3 times with deionized water and ethanol, and dried at 100°C for 2 hours, and finally the dried powder was calcined in a muffle furnace at 700°C for 4 hours to obtain a light yellow powdery nickel tungstate sample .

[0032] (2) Preparation of cadmium sulfide / nickel tungstate composite photocatalyst: Weigh 0.1g nickel tungstate and add it to 70ml ethylene glycol, stir magnetically for 1h, then add 0.055296g cadmium acetate, continue ultrasonication for 1h, then add 0.0156g s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com