Blockage clearing device for cullet in articulated chute and blockage clearing method

A broken glass and chute technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of chronic physical injuries of workers, large differences in broken glass sizes, and waste of labor, etc. The effect of reducing the risk of deformation of the chute, avoiding the splash of broken glass, reducing the risk of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

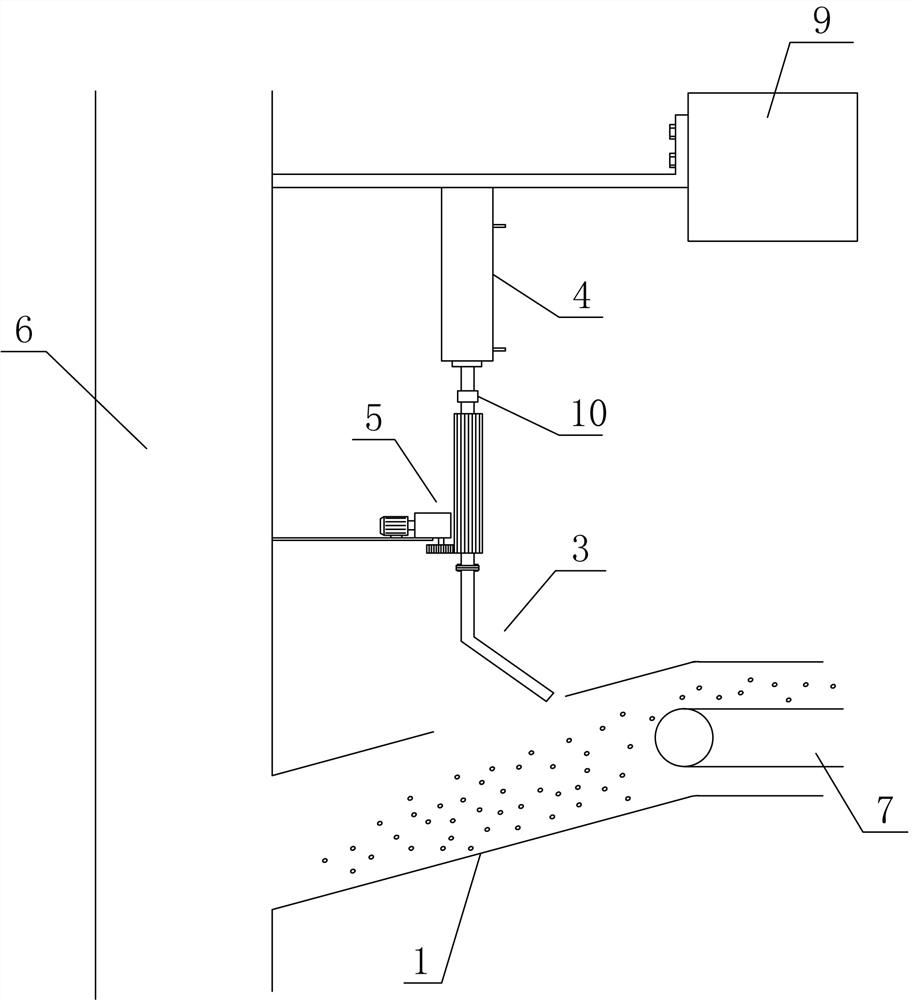

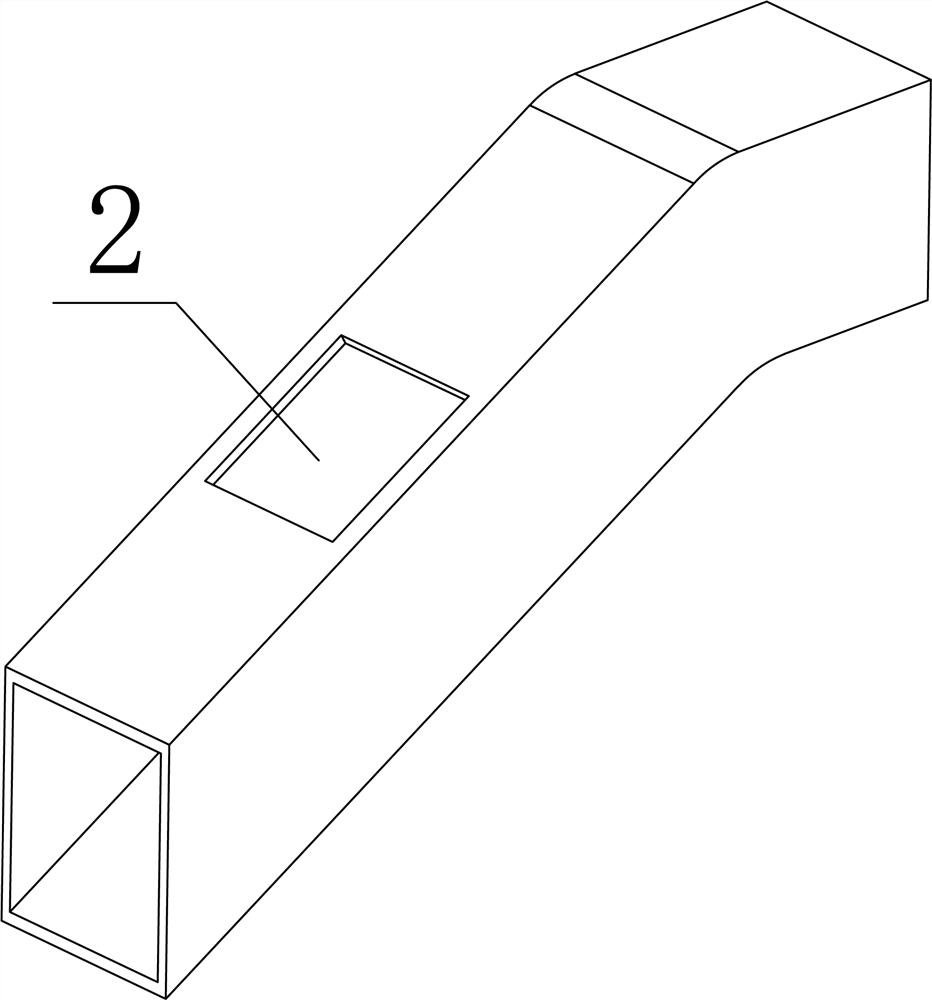

[0050] The preferred solution is as Figure 1 to Figure 3 As shown, a broken glass chute unclogging device includes a chute 1, the top surface of the chute 1 is provided with a deblocking operation hole 2, and the deblocking operation hole 2 is used to provide a moving space for the deblocking stirring member 3, and the deblocking The agitator 3 is driven to move up and down by the lifting device 4 , and the clogging agitator 3 is driven to rotate by the rotary drive device 5 . The clogging stirring member 3 is used to stir the cullet in the chute 1 .

[0051] Such as figure 1 As shown, the chute 1 is arranged obliquely, the lower end of the chute 1 is connected with the bucket elevator transportation passage 6, and the bucket elevator transportation passage 6 is used for installing the bucket elevator, and the upper end of the chute 1 is provided with a feeding belt 7, which is used for For transporting broken glass. Lifting device 4 is fixed by support beam, and described...

Embodiment 2

[0059] On the basis of embodiment 1, introduce as follows with more optimal technical scheme:

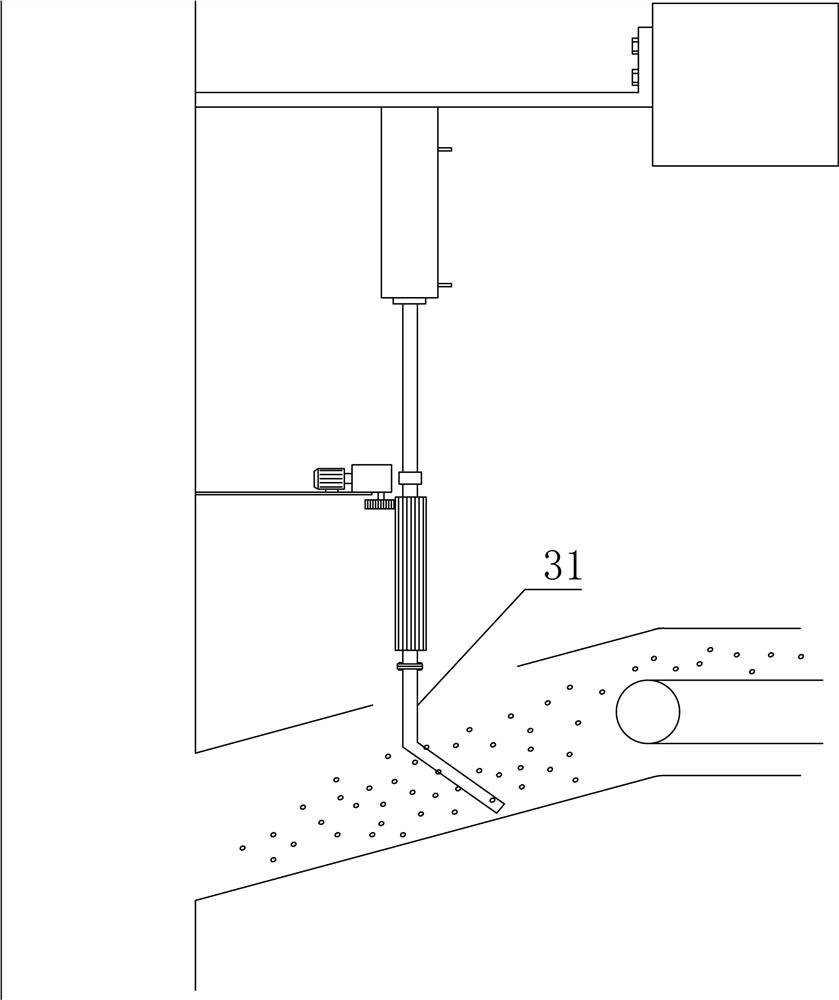

[0060] In embodiment 1, although the chute pipe clearing device can play a good clearing effect, the problem is:

[0061] First, the caliber of the unclogging operation hole 2 is relatively large. When the broken glass is unblocked, the broken glass may splash out from the unblocking operation hole 2, which poses a safety hazard;

[0062] The second, the plug-clearing stirring member 3 is a folded rod 31, and if the folded rod 31 wants to enter into the cullet pile, the folded rod 31 needs a large force to squeeze the broken glass downwards, and the extrusion force increases not only The power requirements of the lifting device 4 are high, and the slide pipe 1 is likely to be extruded and deformed.

[0063] Based on the above problems, this embodiment proposes an improved technical solution:

[0064] The preferred solution is as Figure 4-6 As shown, the block removal stirring me...

Embodiment 3

[0070] On the basis of embodiment 2, introduce as follows with more optimal technical scheme:

[0071] The preferred solution is as Figure 7-11 As shown, the bottom of the stirring rod 33 is a cone structure, and the bottom of the cone is rotatably provided with a ball 35 . The design of the ball 35 can reduce the friction between the stirring rod 33 and the inner wall of the chute 1 when the stirring rod 33 is bent.

[0072] Preferably, a material level gauge 8 is provided near the blockage removal operation hole 2, and the material level gauge 8 is used for detecting material level blockage.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap